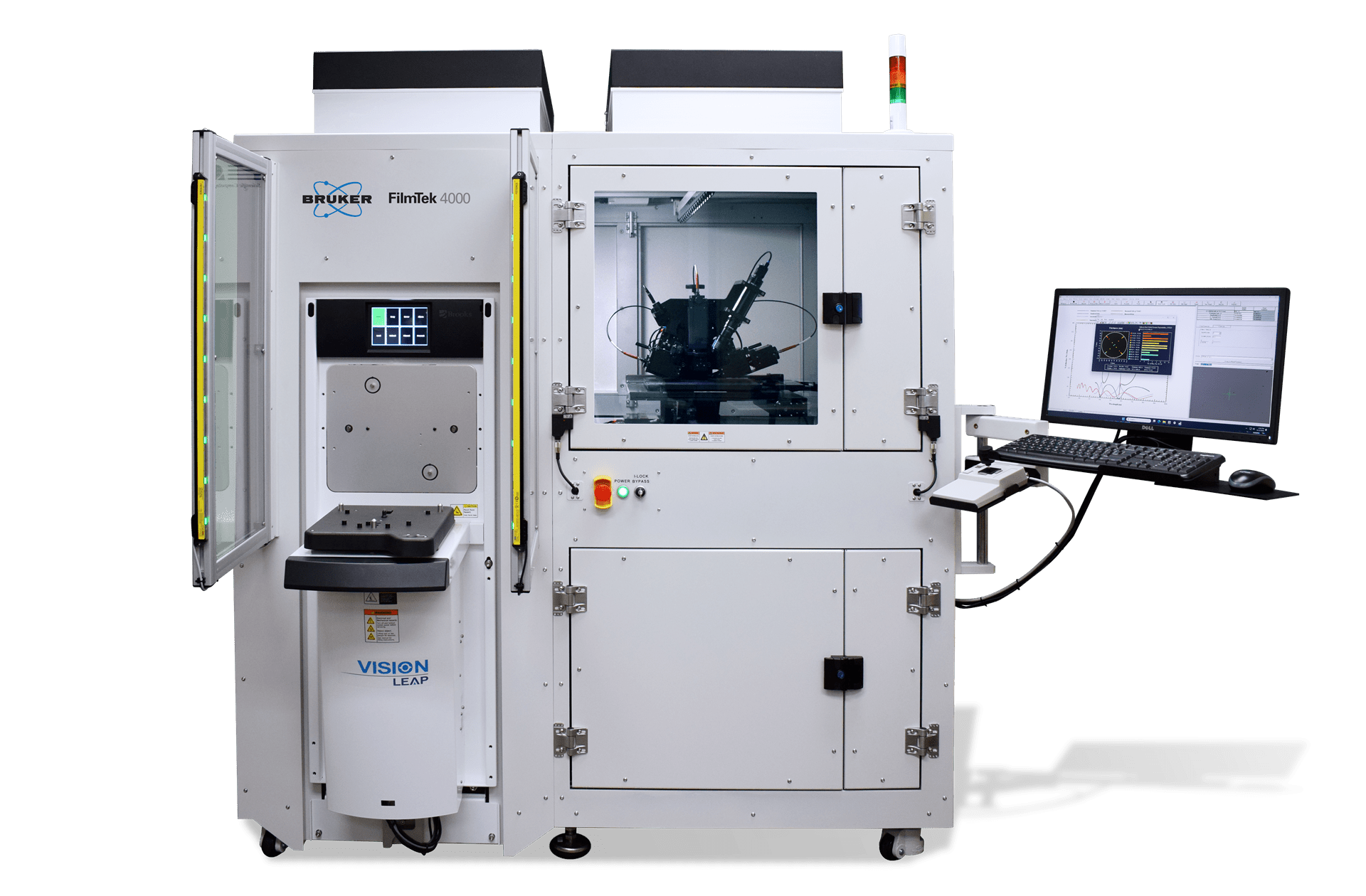

FilmTek 4000 Robotic

FilmTek 4000 Robotic

FilmTek™ 4000 is fully equipped to provide exceptional real-time in-line monitoring of film thickness and optical properties index of refraction (n) and coefficient of extinction (k). The system utilizes a patented multi-angle reflectometry design to collect reflectance spectra from 400 nm to 920 nm and can be customized to extend capabilities to the NIR wavelength range and to accommodate ultrathin film measurements. FilmTek 4000 is a fully automated, non-destructive optical property and thickness metrology tool specifically designed to address the demanding process control needs of silicon photonics, photonic integrated circuits, and planar waveguides.

Ultimate Refractive Index Precision and Resolution

FilmTek 4000 has a refractive index measurement precision 100 times higher than any other optical techniques and 10 times higher than contact systems like prism couplers. Its resolution is up to 2x10-5, equal to the challenge of matching increasingly tighter tolerance specifications.

These capabilities are enabled by a specialized optical design and Bruker’s patented multi-angle differential power spectral density (DPSD) analysis capability.

Full Automation for In-Line Metrology

FilmTek 4000 delivers seamless integration into in-line production environments that require real-time process control feedback. It enables 300 mm wafers to be loaded automatically with results uploaded to the host network, and performs automated beam alignment, calibration, and focusing to ensure consistently accurate results.

Typical Application Areas

Inline Semiconductor Manufacturing

Perform fast, accurate, and repeatable multi-layer film thickness and refractive index measurements on patterned device wafers for semiconductor manufacturing.

FilmTek systems enable process control of oxides, nitrides, ONO, Oxide / Nitride / Cu, polysilicon / oxide, AlN, TaN, TiN, SiGex and composition control, resist, Si3N4/GaAs, ARC, gate oxide, and GaAs films, CMP on Cu, and many other materials encountered throughout the entire wafer fabrication process.

Multi-layer Thin Films

Collect accurate, precise production measurements of thin films and multi-layers on patterned device wafers for front and back-end manufacturing.

Filmtek advanced multi-angle and multi-modal technology enables in-line composition control (e.g., %Ge in SiGex) for thin films, Oxide / Nitride / Cu, CMP process monitoring, and measurement of thin metal oxide thickness (SnO, CuO, InO) with sub-Angstrom repeatability to prevent non-wet open failures in bonding processes.

Silicon Photonics

Measure film thickness and refractive index with a 10x performance advantage over the best prism coupler contact systems.

Filmtek non-contact multi-angle reflectometry systems deliver precise high-resolution measurements and enable automated, in-line process control for a wide range of planar waveguide and silicon photonics applications (e.g., SiON, Si3N4, Ge-SiO2, P-SiO2, BPSG, APOX, HiPOX, and multi-layer SiO2/ SiON film stacks).

Index of Refraction as a Function of Temperature

FilmTek 4000 provides exceptionally high accuracy for index of refraction measurements taken as a function of temperature.

Fully Automated Multilayer Thickness Metrology

With FilmTek 4000, accurate multilayer thickness results are be obtained from stacks like this thermal Si3N4 on CVD Si3N4. This capability can be fully automated, from wafer-loading to alignment and data processing.

Automated multilayer thickness measurements are especially valuable for Si photonics applications.

FilmTek 4000 Select Specifications

Each wafer manufacturing facility and semiconductor fab has its own specific requirements and challenges. Our listed product specifications and offerings are always a starting point for a conversation with our experts to determine how our capabilities can meet your needs.

| Film Thickness Range | 0 Å to 250 µm (with SE option) |

|---|---|

| Film Thickness Accuracy | ±1.5 Å for NIST traceable standard oxide 5000 Å to 1 µm |

| Precision (1σ) | 5 µm Oxide (t,n): 2Å / 0.00002 |

| Spectral Range | 380 nm - 1700 nm (380 nm - 1000 nm is standard) |

| Measurement Spot Size | 1 mm (normal incidence); 2 mm (70°) |

| Spectral Resolution | Visible: 0.3 nm / NIR: 2 nm |

| Light Source | Regulated halogen lamp (10,000 hrs lifetime) |

| Detector Type | 2048 pixel linear CCD array / 512 pixel cooled InGaAs CCD array (NIR) |

| Automated Stage | 2000 mm or 300 mm |

| Computer | Multi-core processor with Windows™ 11 Operating System |

| Measurement Time | <5 sec per site (e.g., oxide film) |

| DOWNLOAD THE BROCHURE TO SEE FULL SPECS LIST | |

How Can We Help?

Bruker partners with our customers to solve real-world application issues. We develop next-generation technologies and help customers select the right system and accessories. This partnership continues through training and extended service, long after the tools are sold.

Our highly trained team of support engineers, application scientists and subject-matter experts are wholly dedicated to maximizing your productivity with system service and upgrades, as well as application support and training.