Restricted Materials Screening (RoHS)

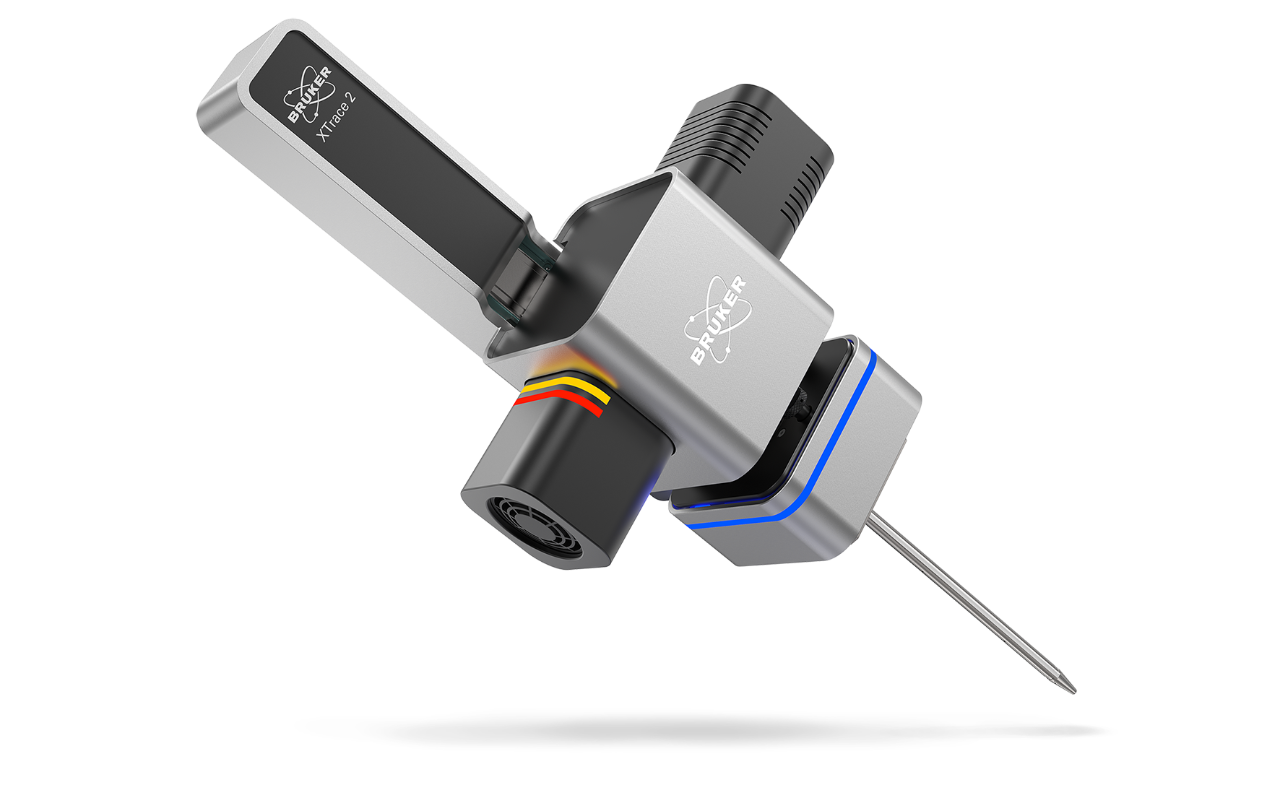

Restricted Material Screening with micro-XRF

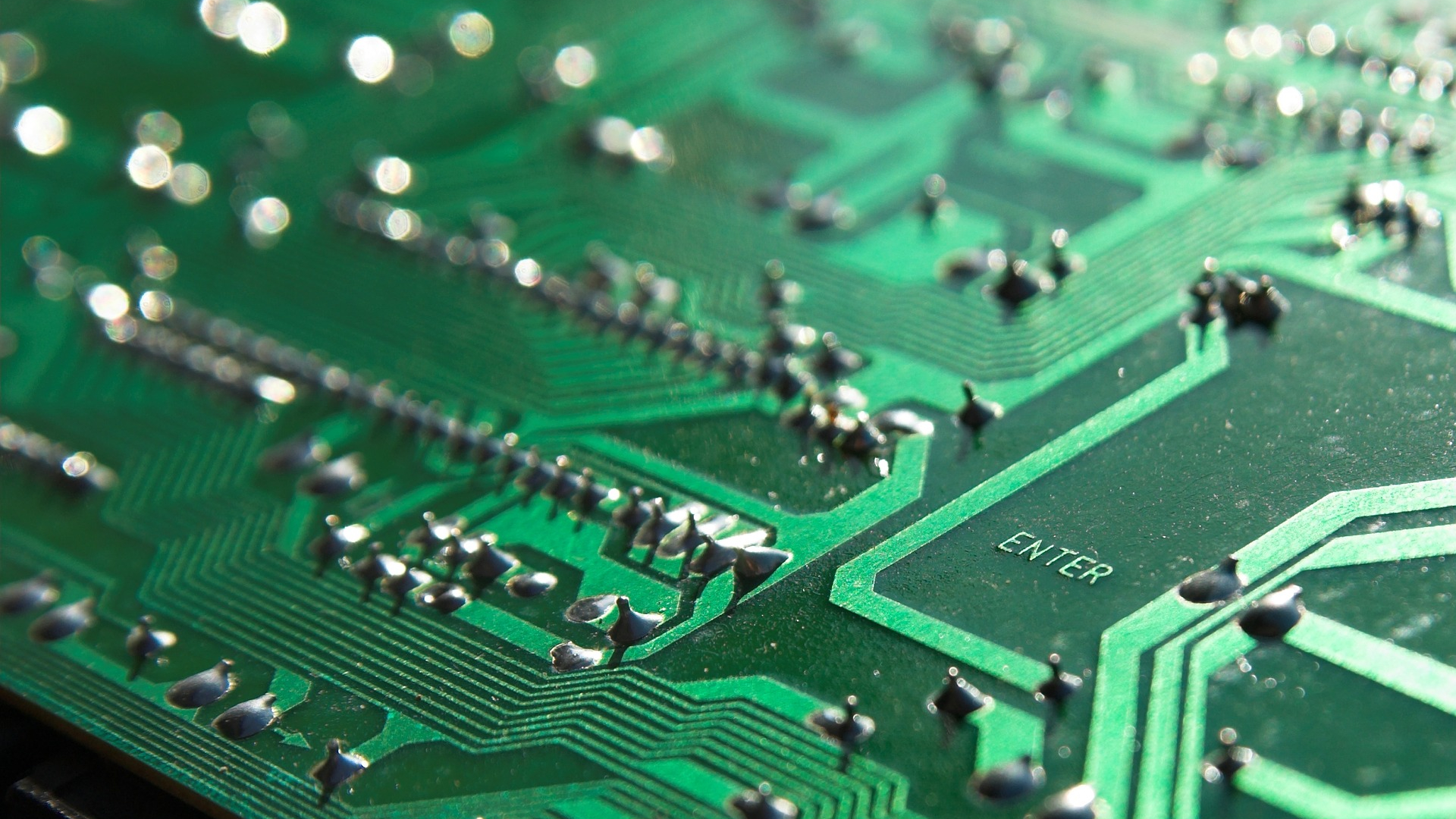

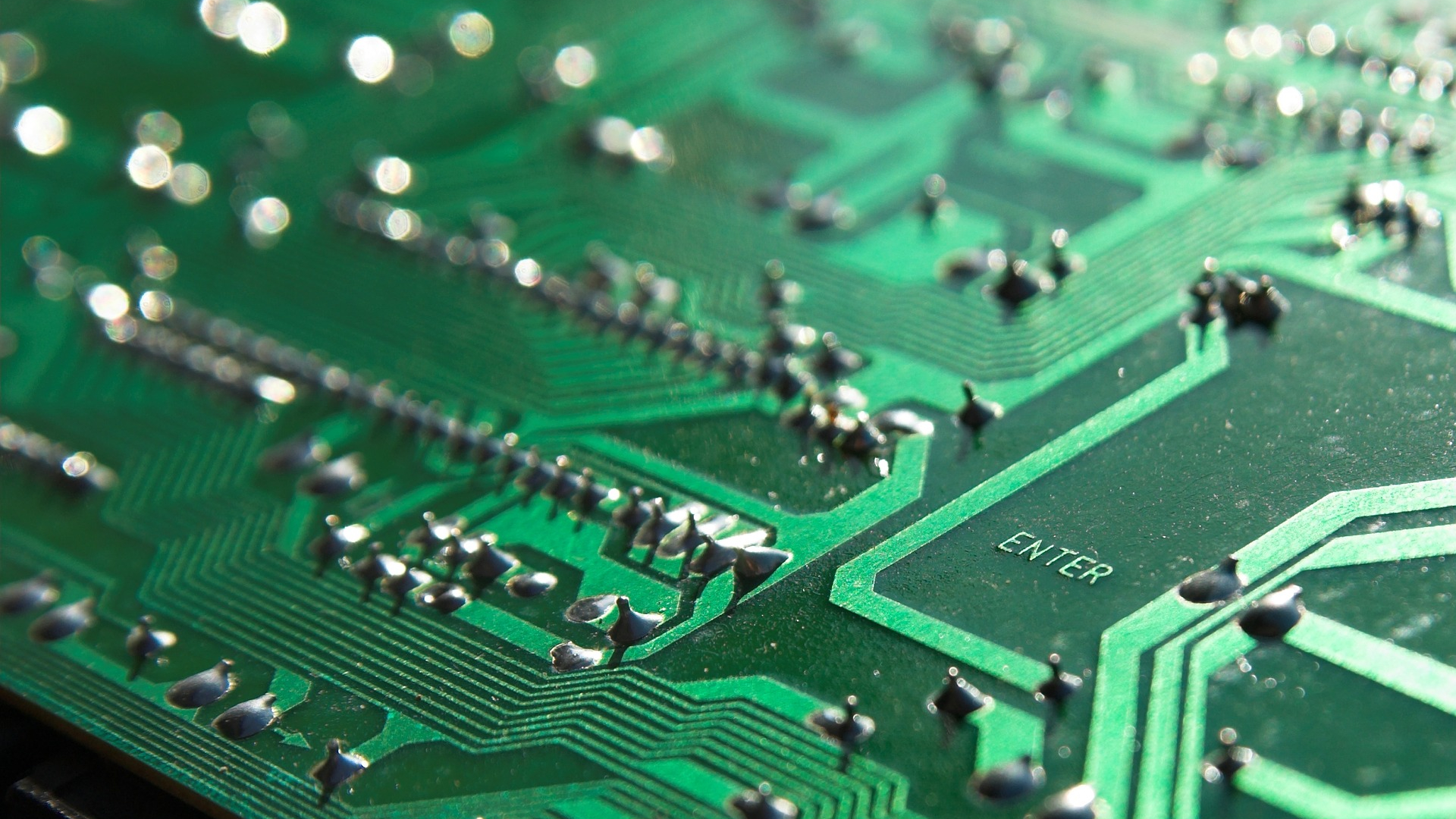

With the increasing presence of electronic devices, electronic waste is also being produced faster than ever before. In recent years the EU and other countries have established multiple regulations to promote recycling of e-waste and reduce the health and environmental risks associated with the increase in e-waste production. RoHS directive (Restriction of the use Of certain Hazardous Substances) is one of those rule sets aimed at reducing hazardous material from entering e-waste streams by restricting their use in electronic equipment. These restricted materials include heavy metals (lead, mercury, cadmium), hexavalent chrome, polybrominated flame retardants (PBB and PBDE) and phthalates.

X-ray fluorescence (XRF) offers a fast, non-destructive method of screening for these restricted elements. Small spot analysis is important for successful analysis, since the analysis beam must match the sample size which makes M4 TORNADO micro-XRF perfect choice for RoHS screening. For RoHS screening selectable collimator between 0.4 mm and 1.5 mm allows accurate analysis on individual components and cables, as well as bulk samples (metals, solder, raw materials) and large circuit boards.