Application Note: Adhesion Testing of Photosensitive Insulators to Passivation Layers Under Controlled Humidity

Realistically Evaluating Adhesion Performance with In-Situ Testing

Photosensitive polymer films are widely used in microelectronics packaging as a protective dielectric layer. Adhesion quality between the polymer and underlying passivation layer determines the organic film’s performance, and adhesion quality is affected by the high temperatures and humidity regularly experienced by devices. To simulate the effects of realistic conditions, nanoindentation-based adhesion testing has traditionally been conducted after simulated environmental exposure (ex-situ). There are, however, significant advantages to instead conducting in-situ nanoindentation-based adhesion testing—capturing both reversible and permanent effects in real time.

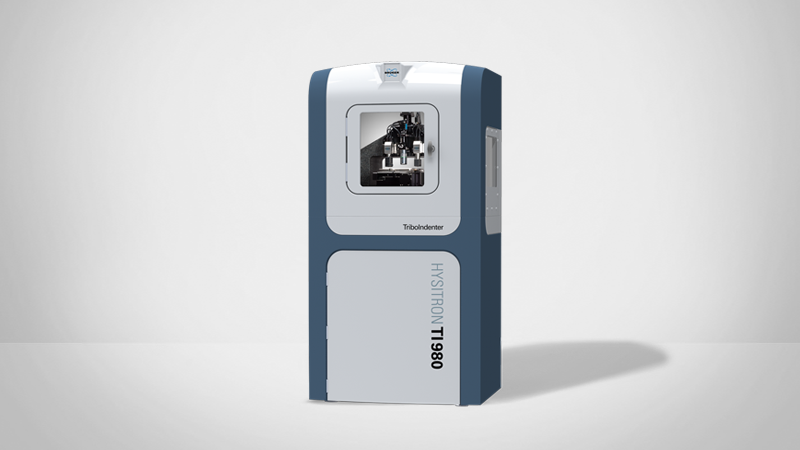

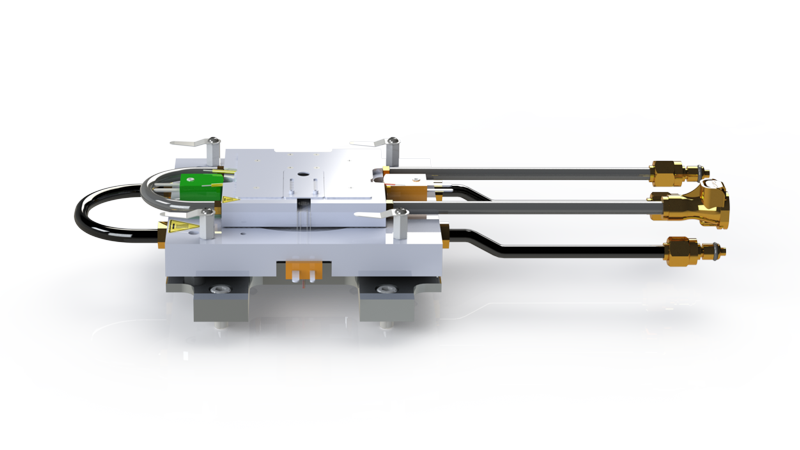

This application note utilizes a Hysitron TI 980 TriboIndenter® equipped with the xSol® Humidity module to enable direct, in-situ mechanical characterization of a nitride/polymer interface under controlled temperature and relative humidity. It is found that relying exclusively on ex-situ tests after aging can lead to an overestimation of interface reliability

Readers can expect to find:

- Real-time mechanical characterization of nitride/polymer interfaces under varying humidity and temperature

- Side-by-side comparison of in-situ and ex-situ nanoindentation for PBO films on SiN substrates

- Insights into the limitations of ex-situ testing for predicting real-world device reliability

KEYWORDS: Nanomechanical Test Instrument; Hysitron; AN1550; Bruker; Application Note; TriboIndenter; Humidity Testing; Polymers; xSol; TI 980

Environment-Driven Adhesion Degradation

Photosensitive polymeric dielectrics with micrometric thickness are widespread in microelectronic devices with non-hermetic packaging. These organic films are usually interjected between traditional inorganic passivation layers and the outer encapsulation material (e.g., epoxy molding compound) to provide mechanical protection, electrical insulation, and an additional barrier against moisture penetration into the active device. Consequently, the performance of the organic insulator strongly depends on adhesion quality between the polymer and the underlying inorganic passivation. These interfaces often face challenging environmental conditions, such as high temperature and humidity, which can degrade adhesion and compromise device reliability.

Traditional adhesion testing methods involve ex-situ nanoindentation performed after environmental aging treatments. However, this approach may not accurately capture the realtime mechanical behavior of the interface under operational conditions, as post-aging recovery phenomena could conceal the true extent of degradation. The following study compares in-situ nanoindentation-based adhesion testing with traditional ex-situ testing for a photosensitive polybenzoxazole (PBO) film deposited on silicon nitride (SiN).

Experimental Setup

Two types of SiN substrates were investigated: standard stoichiometric SiN (Si/N 0.8 at%) and Si-rich SiN (Si/N 1.1 at%), both coated with a 9 µm PBO film deposited via electrospinning. The samples were subjected to ex-situ and in-situ adhesion testing with nanoindentation under varying environmental conditions, as reported in Figure 1.

In-Situ Testing Results

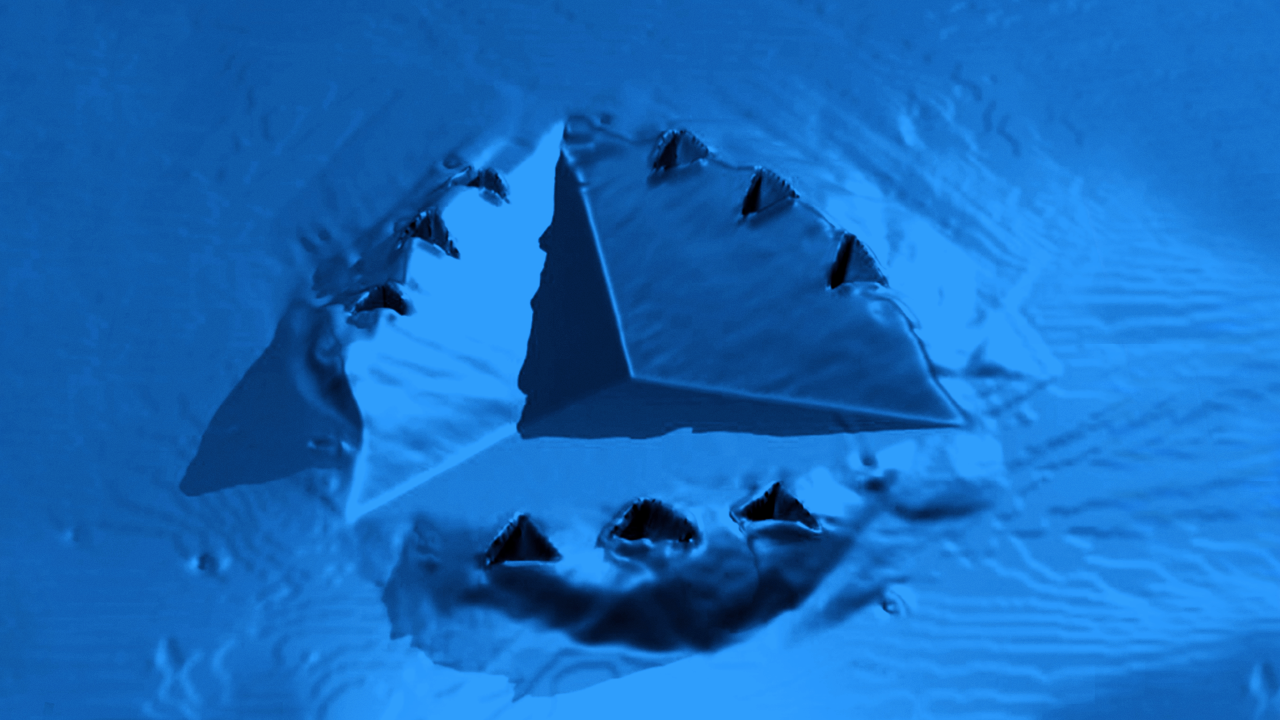

In-situ nanoindentation measurements using the xSol Humidity module revealed a clear decrease of adhesion strength with increasing dew point, as illustrated in Figure 2. The critical delamination load, determined from a visible local decay of slope in the load-displacement curve, decreased consistently with increasing dew point for both standard and silicon-rich SiN substrates (Figure 2a). Simultaneously, the delaminated area increased with the ambient dew point, as evidenced by optical micrographs of residual indents (Figure 2b). Brightness thresholding was employed to segment the outer ring of delamination, which manifests as a region of locally brighter contrast. These observations suggest that moisture uptake by the PBO film, along with the associated swelling and interfacial weakening, are directly correlated with the ambient moisture dew point.

Importantly, the mechanical compliance of the PBO remained relatively stable across all tested environments, confirming that the observed changes in critical load were mainly attributable to variations in interfacial adhesion, rather than in bulk polymer properties. Notably, despite differences in SiN stoichiometry, PBO exhibited similar adhesion degradation versus dew point profiles with both samples, suggesting that environmental conditions are the dominant factor influencing adhesion loss.

Comparison with Ex-Situ Testing

Complementary ex-situ tests were conducted on identical samples after aging in a climatic chamber at elevated temperature and humidity for durations of two and seven days. After aging, the samples were removed and tested under ambient laboratory conditions. Results reported in Figure 3 showed a markedly different adhesion behavior compared to in-situ testing. After two days of aging (not reported), the critical delamination load values largely recovered to levels comparable to initial ambient measurements. Even after seven days of aging (Figure 3, dashed lines), only a slight permanent adhesion loss was observed, without clear correlation to the severity of the aging environment. Results reported in Figure 3 showed a markedly different adhesion behavior compared to in-situ testing. After two days of aging (not reported), the critical delamination load values largely recovered to levels comparable to initial ambient measurements. Even after seven days of aging (Figure 3, dashed lines), only a slight permanent adhesion loss was observed, without clear correlation to the severity of the aging environment.

As compared to in-situ results (Figure 3, solid lines), ex-situ testing underestimates the extent of adhesion degradation occurring during exposure to harsh conditions. This suggests that aging (meaning a permanent change of physical properties) is not the only cause of adhesion degradation, and that the current moisture level plays a dramatic role in weakening (reversibly) the interfacial strength, which can recover. The recovered strength is likely due to rapid desorption of moisture upon returning to ambient conditions.

xSol Humidity Enables Realistic Evaluations of Adhesion Performance

Bruker’s xSol Humidity module enables real-time measurements under controlled temperature and humidity, revealing that current exposure to a given moisture level leads to more SiN/PBO adhesion degradation as compared to being aged in comparably harsh conditions. Partial or total recovery of PBO adhesion may be due to fast moisture desorption. This potentially leads to an overestimation of interface reliability when relying exclusively on ex-situ tests after aging.

The comparison between in-situ and ex-situ adhesion testing highlights the critical role of recovery time in accurately assessing the interfacial reliability of photosensitive insulators on passivation layer interfaces. In-situ nanoindentation with environmental control provides a more realistic and comprehensive evaluation of adhesion performance, capturing both reversible and permanent effects induced by critical environments. This approach is essential for developing and qualifying robust polymer/inorganic interfaces in microelectronic devices.

Authors

- Eric Hintsala, Ph.D., NI Applications Development Manager, Bruker (eric.hintsala@bruker.com)

- Filippo Sabatini, Ph.D. candidate, Politecnico di Milano and STMicroelectronics

- Emanuele Cattarinuzzi, Ph.D., Characterization and Modeling Engineer, STMicroelectronics

- Vincent Coutellier, Characterization and Modeling Engineer, STMicroelectronics

©2025 Bruker Corporation. All rights reserved. Hysitron, TriboIndenter, and xSol are trademarks of Bruker Corporation. All other trademarks are the property of their respective companies. AN1550, Rev. A0.