Grade Control

Quality Grade Control

Bruker helps achieve the goal of mine profitability by providing reliable instrumentation exactly where and when it is needed. We are your partner in maximizing value and reducing risk in the process of providing tonnes at optimum grade to the mill.

Bruker is committed to providing more than just instrumentation, we provide solutions for grade control and impurity identification with:

- Accurate analysis with calibrations designed for the mineral industry and the tools needed to ensure ongoing data validation and data integrity

- A commitment to supporting mining operations with expertise and resources specifically tailored for mining

- A recognition that long-term cost of ownership is important, and commitment to meeting the service needs of our customers over the lifetime of mine projects from exploration to remediation and closure

Bruker’s solutions approach to mining means that our experts will help you select the best instrumentation, software, and calibrations needed for your project. We empower the selection of the right analytical technology to calculate grade, tonnage or contained metal at each step in the mining value chain.

EDXRF for Grade Control

Energy dispersive X-Ray Fluorescence (XRF) is the most trusted method for grade control in mines and mineral processing facilities. Bruker’s XRF analyzers allow for the simultaneous analysis of elemental concentrations required for identification of grades, sub-grades, and waste. Bruker’s solutions are focused on maximizing value and reducing risk along the entire mining value chain from mine-site portable XRF analysis to high throughput grade control and impurities workflows. Solutions include:

The high-capacity benchtop S2 PUMA Series 2 capable an analyzing from C to Am with options for one, 12, and 20 sample changers.

WDXRF for Grade Control

Wavelength dispersive XRF (WDXRF) provides the most accuracy and lowest limits of detection, particularly in complex ores. WDXRF uses X-ray optics to disperse the fluorescence into individual wavelengths for each element. The resulting spectrum has a low background and eliminates most element overlaps. This technology is critical for grade control applications where discrimination of trace elements or elements with many overlaps is important. Bruker’s solutions for WDXRF

The S8 LION provides the fastest time-to-result as a multi-channel WDXRF. Analyze up to 16 elements simultaneously for high throughput grade control and impurity applications where precision at low detection limits is required.

The S8 TIGER Series 2 is a robust and easy-to-use sequential WDXRF capable of providing major and trace elements in a single run. The S8 TIGER provides the analytical flexibility required for demanding and diverse supervision of mining or stockpile management.

The S6 JAGUAR is a compact WDXRF that is small and fast enough to be deployed to mine-site laboratories but powerful enough to meet the needs of the most demanding grade discrimination.

Grade Control with Mineralogy

Complex ores often require mineral identification as part of the grade control workflow. For example, kaolinite can substitute for goethite in iron ores and cannot be identified visually. It can also be desirable to quantify mineral assemblages when assigning grade blocks to high grade, low grade or waste rock. Rapid X-Ray Diffraction (XRD) combined with cluster analysis is an emerging tool for mineral-based grade control and impurity analysis. When mineral associations are a key discriminator in grade control and bulk element or mineral content doesn't tell the whole story - automated mineralogy steps in to provide additional information key for mineral processing. Bruker’s solution for minerology in grade control include:

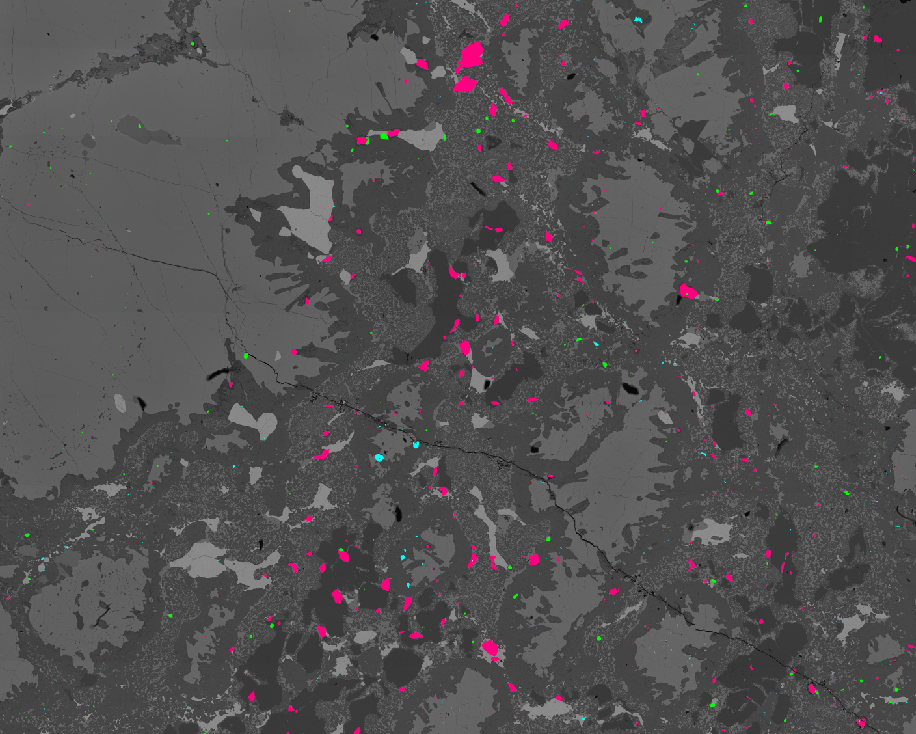

AMICS is Bruker’s automated mineralogy solution for scanning electron microscopes. AMICS automates the collection of backscatter electron and EDS X-ray points to make mineral maps to calculate locking, liberation, and modal minerology.

The D6 PHASER delivers XRD analysis at the speed required for grade control analysis in a compact desktop package.

The DIFFRAC.SUITE™ software provides all the tools needed for grade control and quantitative analysis for grade sorting. The PolySNAP module provides the cluster-analysis while the TOPAS software allows profile fitting and quantitative Rietveld analysis.

Automation Systems for Grade Control

Mining is undergoing a revolution in technology adoption and automation. The incorporation of analytical technology into the connected mine has become a priority for the global mining industry. XRF and XRD analysis provide critical inputs into mining operations models and stockpile management. By incorporating elemental and mineral data directly into automated sample preparation systems, Bruker’s instruments can provide real time data to decision makers. Bruker is committed to making the system integration process as painless as possible.

- Many products come ready with a API and configurations to accept samples.

- Dedicated teams for special projects, hybrid instruments, and unique solutions