Fiber Manufacturing

Quality Inspection of Fibers in Manufacturing by FT-IR

In order to chemically characterize natural and synthetic as well as organic and inorganic fibers, FT-IR microscopy is an extraordinarily effective tool. Due to its ability to measure with a high lateral resolution, the presence of a single fiber is usually sufficient to perform an analysis.

It does not matter whether it is an analysis of the fiber itself, its coating or chemical functionalization. FT-IR provides precise information about the chemical composition and properties of the fiber and can thus provide vital data for quality control applications.

Development and Research on New Fiber Materials by FT-IR and Raman

Innovation is one of that key differentiators that is becoming increasingly important. Whether it is self-repairing, intelligent, electrically conductive or new, highly resistant fiber materials, Raman and FT-IR can help in their discovery.

FT-IR spectroscopy and microscopy enable chemical characterization and quantification of contents in bulk or microscopic samples. By adding time-resolved spectroscopy to the mix, it is also able to investigate chemical reactions making it an material research powerhouse.

In direct comparison, Raman spectroscopy and microscopy offers an even higher spatial resolution for microscopic applications, all the way to the investigation of nanofibers (≥ 0.5 µm). Especially for carbon and carbene fibers or any other carbon analog, Raman offers decisive advantages that benefit all materials research.

Application of XRM in woven and non-woven fabrics

Functional clothing nowadays consists of high-tech textiles made of natural or synthetic fibers. Key properties such as permeability or thermal isolation strongly depend on the fiber orientation and packing density.

The same is also true for non-woven fabrics such as paper products or filtering materials in regards of their mechanical strength or hydraulic properties respectively.

X-ray microscopy supports product developments by providing a thorough understanding and analysis of the 3D microstructure and fiber orientation.

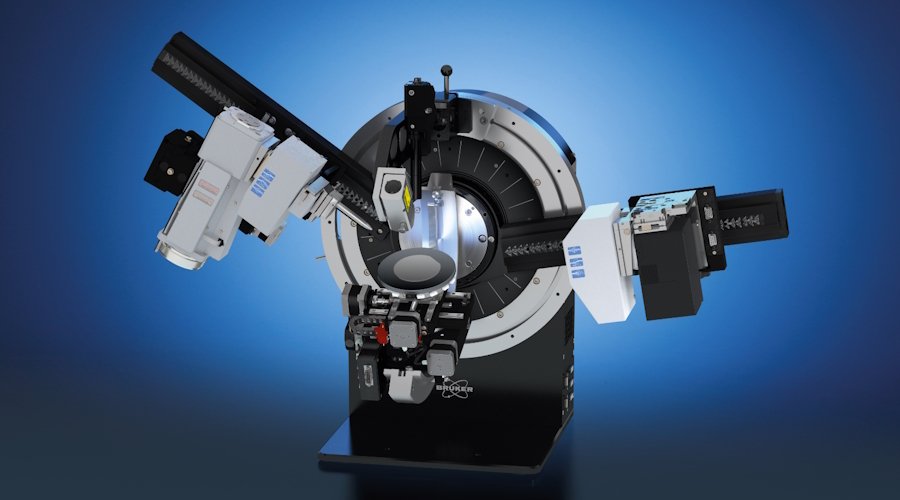

Orientation and Nanostructure Analysis of Fibers

Similar to how a rope is made from many strands, polymers and organic fibers are often made of many intertwined molecules. The orientation, size and interconnected structure of these fibers on the nanoscale strongly influence their bulk properties. X-ray Diffraction and Small Angle X-ray Scattering offer a window into this nanoscopic world by revealing the length scales and degree of orientation of these nano-features.