Aluminum

Aluminum

Aluminum is a versatile metal found in everyday objects and products such as soda cans, smartphones, cars, and airplanes parts. The industry is facing two challenges, increasing the production to satisfy the demand for lightweight material in the automotive sector, and finding more energy efficient technologies and methods to make the aluminum production and recycling more environmentally friendly.

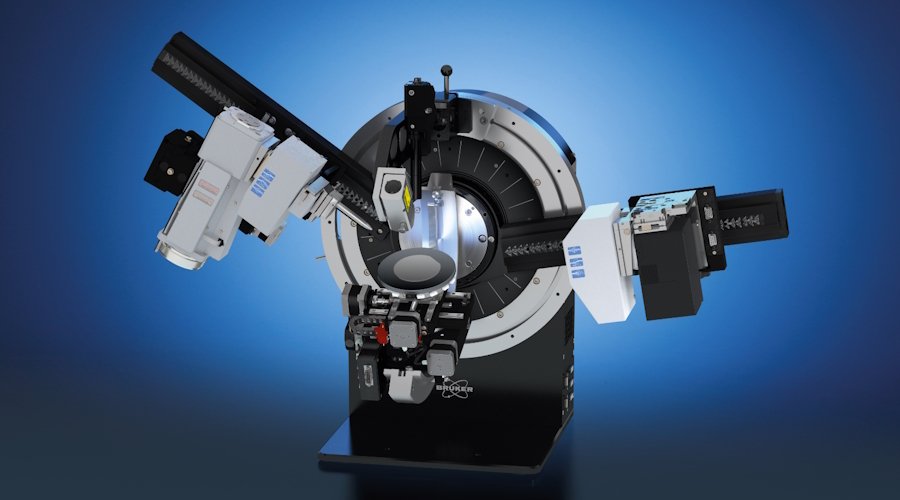

Detailed studies of the mechanisms involved in recovery and recrystallisation during heat treatment can be done quantitatively with SEM-based analytical techniques instead of using TEM. QUANTAX EDS , EBSD and ARGUS™ provide a fast and quantitative identification of the chemical elements, microstructural and crystal orientation down to the nanoscale. In addition, it is easy to use, non-destructive and relatively inexpensive. The benefit of a large field of view compare to TEM is also required when inspecting large fraction of samples for surface quality control of aluminum products. Surface quality is important since it can influence the corrosion resistance and adhesive bonding and durability.

Abrasion in Production Lines Can Be a Source of Contaminated Products and/ or Malfunctioning Machinery

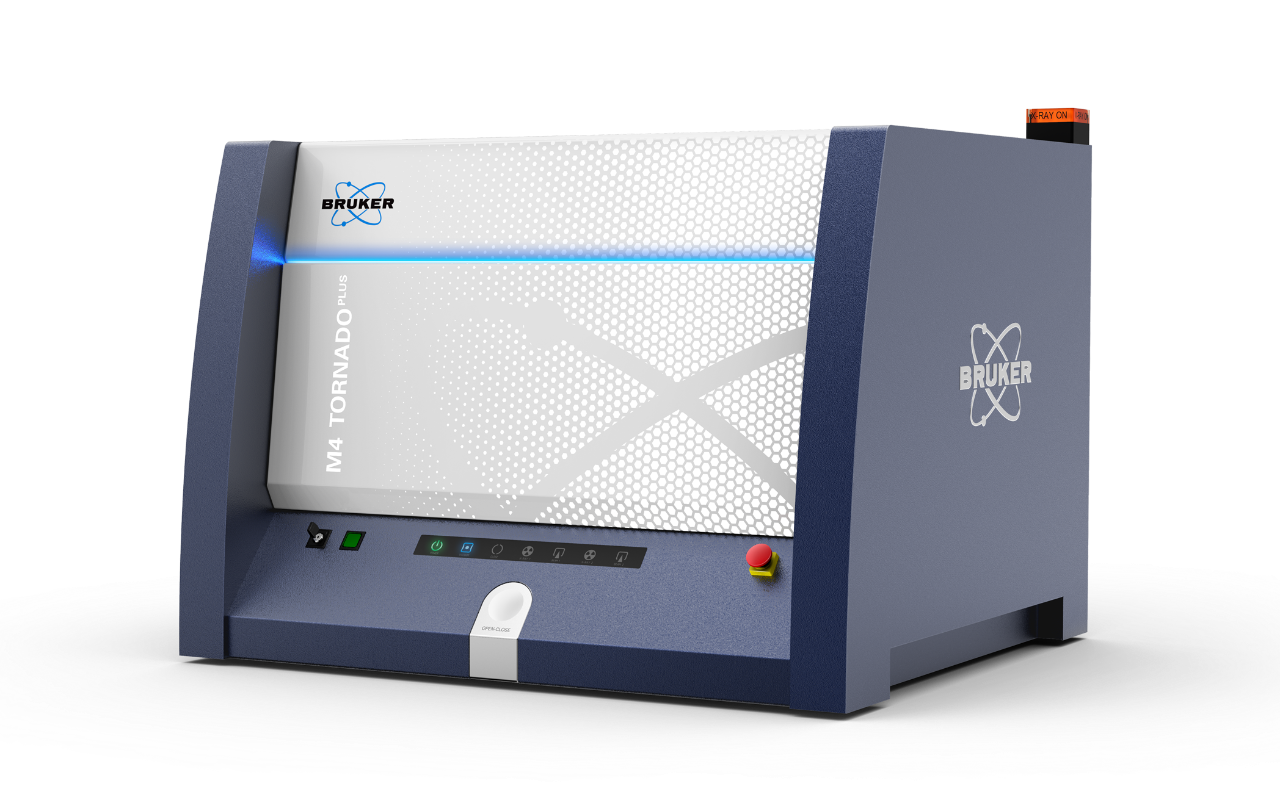

Abrasion in production lines can be a source of contaminated products and/or malfunctioning machinery. Using micro-XRF is straight-forward to classify steel particles with sizes down to 50 µm because their heavy matrix will allow a reliable quantitative analysis of the main elements. For the classification of Aluminum flakes usually heavy elements are of importance, whereas the main element is very light. Therefore, it is difficult to asses the alloy type of thin aluminum particles. The fast mapping capabilities of the M4 TORNADO (PLUS) allow quick scanning of small Al particles and find the thickest part of the sample. This thick region is likely to give the most reliable results for a classification. The region of interest can be cut out from the Hypermap dataset and be quantified for classification.

The production of aluminum in the smelter is uniquely controlled by Powder XRD. Hundreds of samples of the hot molten electrolyte are regularly taken, cooled down and analyzed with the D8 ENDEAVOR Aluminum editon. The volume texture of the final metal product can be inspected by XRD.

Texture Analysis of Rolled and Drawn Aluminum Sheets

The orientation distribution of grains in a polycrystalline material, commonly referred to as its crystallographic texture, has a profound impact on its mechanical, electrical, and thermal behavior. Commonly, manufacturing processes such as machining, rolling, extruding, and drawing lead to changes in texture which can be measured and controlled to enhance functionality or prevent failure. X-ray Diffraction provides an easy to use non-destructive method for the determination of crystallographic texture.

Aluminum Electrolytic Bath Analysis

A major cost factor in Al production is energy for electrolytic smelting of alumina. A melting temperature below 1000 °C is obtained by adding cryolite (Na3CaAlF6), AlF3 and CaF2 to the alumina. The actual composition of such a bath is represented in the mineralogy of the solid cooled electrolyte. This contains chiolite and two forms of Ca-cryolite mixed crystals in addition to the feed material. The bath acidity (ExAlF3) and other control variables are obtained in DQUANT from single XRD peak analysis and the total Ca content that is simultaneously measured by XRF in the D8 ENDEAVOR.

Aluminum Alloys and XRF Aluminum Analysis

Aluminum alloys are very light and have good corrosion resistance and electric conductivity. Cu and Mg alloyed grades are tough; Si alloyed grades can easily be cast. Aluminum alloys are used as construction material of aircrafts, sea crafts, car motors, cans, and containers. Aluminum is also used to cast window frames and can be colored to wide range of colors.

Aluminum alloys fall into the category of light metal alloys and are now easily analyzed using Silicon Drift Detector (SDD) XRF aluminum analyzers.

Aluminum is the most recycled metal

The scrap types are cans, unalloyed and alloyed plates, crushed casts, chips, and slag. Aluminum scrap sorters use portable XRF analyzers, while aluminum producers and foundries use big stationary laboratory analyzers as well as portable analyzers. Aluminum producers are interested in Mg, Si, Ni, Pb, Bi, Cr, Ti, Sn, V, Be, Fe, Zn, Cu, Mn, Ca, Sr, Sb and P. The scrap is analyzed prior to charging to the furnace. As little as 0.003 % Ca can be detrimental in aluminum processing. P can be either an alloying element or a tramp element. As an alloying element, P is 0.008-0.018 %, Sr is 0.001-0.01% and Sb 0.001-0.01%.

Aluminum alloys are broken into the following series:

- 1000 Series: essentially pure aluminum with a minimum 99% aluminum content by weight; can be work hardened.

- 2000 Series: alloyed with copper; can be precipitation hardened to strengths comparable to steel. Formerly referred to as duralumin, they were once the most common aerospace alloys, but were susceptible to stress corrosion cracking and are increasingly replaced by 7000 Series in new designs.

- 3000 Series: alloyed with manganese; can be work-hardened.

- 4000 Series: alloyed with silicon; also known as silumin.

- 5000 Series: alloyed with magnesium; derive most of their strength from solution hardening, and can also be work hardened to strengths comparable to steel.

- 6000 Series: alloyed with magnesium and silicon, easy to machine, and can be precipitation-hardened, but not to the high strengths that 2000, 5000 and 7000 Series can reach.

- 7000 Series: alloyed with zinc; can be precipitation hardened to the highest strengths of any aluminum alloy.

- 8000 Series: miscellaneous category