Beverages

Analysis of Beverages

Infrared and Near-Infrared Spectroscopy, Nuclear Magnetic Resonance, Elemental Analysis and other well-established analytical techniques help our customers worldwide to optimize the production processes for high-quality, pure and authentic beverages.

Many of the raw materials used for producing beverages can be analyzed by FT-NIR spectroscopy. From solid samples like wheat, barley, malt, hops and yeasts to liquids like concentrates.

Most intermediates and products are liquids and analyzed in transmission through a maintenance free quartz flow cell with 1mm (1,000μm) path length that does not show cuvette wear over time. Bruker’s NIR systems allow automating the process of analyzing and cleaning for highest reproducibility and accuracy.

The quality of beverages often reflects the quality of the raw materials used. Are grapes free of contaminants? Is my packing material free of leachable chemicals? What about mycotoxins? There are many questions to ask and answer to ensure a quality product. With our Mass Spectrometry solutions, we can offer a broad range of systems which can answer those challenging questions. In some cases, specific solutions are offered like our unique Corksceener solution.

XRF is a fast, nondestructive technology for elemental analysis of macro-nutrients, micro-nutrients, and heavy metals.Equally important is its ability to screen for toxic metals. Bruker’s Elemental Analyzer portfolio includes high-throughput lab-based ED-XRF and WD-XRF, point-and-shoot handheld XRF, micro-XRF, and ultra-trace analysis TXRF spectrometers.

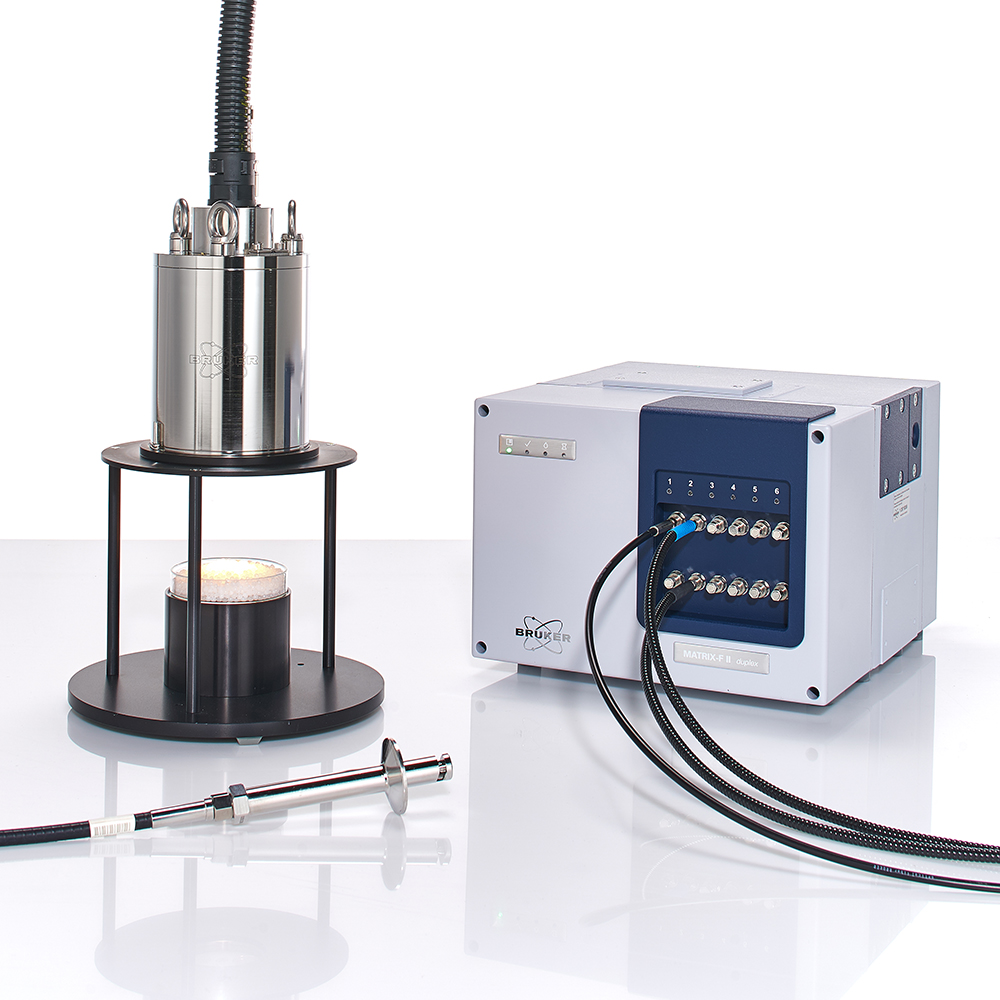

Oxidative staling of beer occurs by a free radical process. During storage, even trace amounts of transition metals such as iron or copper will catalyze the conversion of molecular oxygen to what are known as "reactive oxygen species". Antioxidants in beer help it to resist free radical Oxidation can be minimized by optimizing brewing operations and storage conditions to provide maximum antioxidant content in packaged beer. The EPR oxidation profile technique provides an analytical measure for evaluating the overall antioxidant status of a beer at each stage of the brewing process. Bruker has developed a benchtop electron spin resonance instrument with automation and a software solution designed specifically for measuring free radical oxidation in beer from raw material to packaged product.

Related Videos

Benefits of Benchtop Electron Spin Resonance: An interview with Dr. Heidi Grimmer, head of flavor activity, FlavorActiV.