Importance of Thin Film Mechanical Properties Under Environmental Control

Learn how to control the impact of test conditions on product reliability, process control and regulatory compliance

Product innovation in modern industries—especially the semiconductor, hard coating, and display industries—relies heavily on decreasing the thickness of thin-film components.

We are pleased to present this webinar as one part of our 4-part Thin Film Measurements Series, in which our experts provide the information manufacturers need about leading-edge nanomechanical testing technology for thin films measurement, complete with use case studies for a range of industrial applications.

Collect Accurate Measurements in a Wide Range of Environmental Conditions

Natural and synthetic materials from rubber to metal and plastics affect our everyday. Material mechanical behavior of materials changes in different environments. To ensure and enhance the reliability of a product, it is extremely important to understand the products’ performance in a simulated environment during the production process.

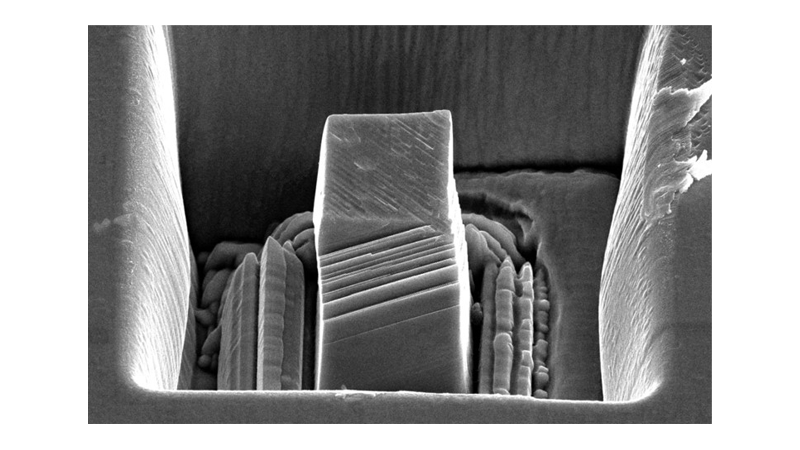

Materials with high environmental sensitivity have been used in multiple industries including interlayer filling in integrated circuits or thin films in flexible display screens. In these industrial applications, how to get accurate mechanical properties under different temperatures and humidity is becoming the main technical challenge for product development or process control. In this webinar, you can expect to:

- Find out how and when to measure thin film mechanical properties and performance under non-ambient conditions.

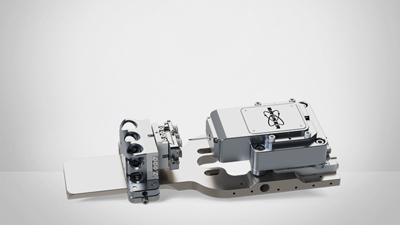

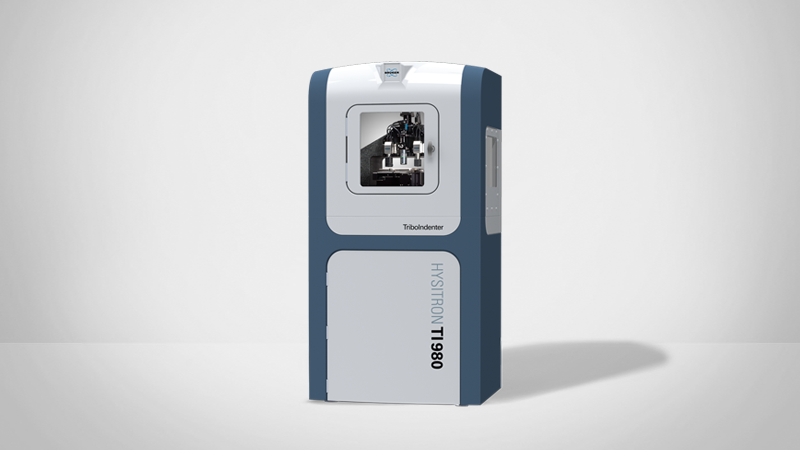

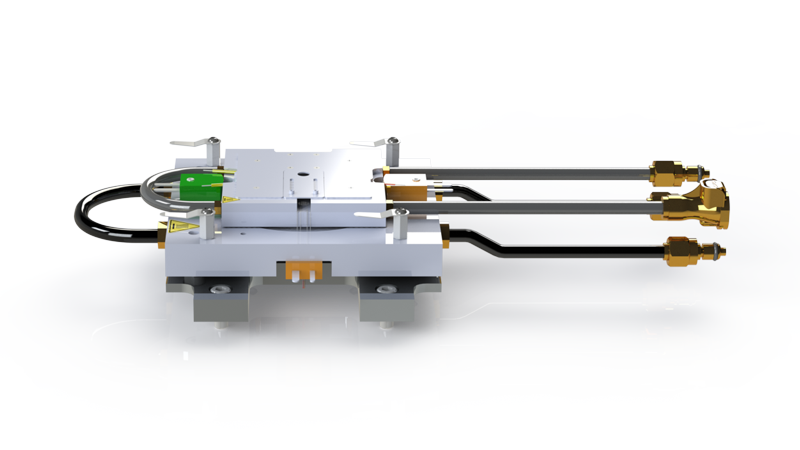

- Understand how to use Bruker's standalone systems (with xSol environmental control chamber) and SEM instruments with our heating stage options.

- See these principles demonstrated through use case studies including samples of glass-based film materials, polymer films, adhesives, silicon films, and superalloys.

Learn about the common measurement challenges of high environmental sensitivity films, Bruker’s technical advantages in the latest thin film mechanics measurement technology development under environmental control.

Find out more about the technology featured in this webinar or our other solutions for Studying Thin Film Mechanical Properties under Environmental Control:

Speaker

Pal-Jen Wei, Ph.D.

Applications Scientist, Bruker

Dr. PJ Wei is an Application Scientist at Bruker Nano Surfaces, responsible for application development and technical support of Nano-Mechanical, Nano-Tribological and Nano-Indentation instruments. His academic background was in mechanical engineering and nano-metrology. Dr. Wei obtained his Ph.D. at National Cheng Kung University, Taiwan; majoring in nano-mechanical properties of thin solid films. Prior to joining Bruker, Dr. Wei was an Assistant Prof. at the Nanotechnology and Micro-system Institute in Taiwan and then a senior engineer of RD department in Catcher Tech. He has published in over 30 peer reviewed international journal papers and has also presented at many international conferences.