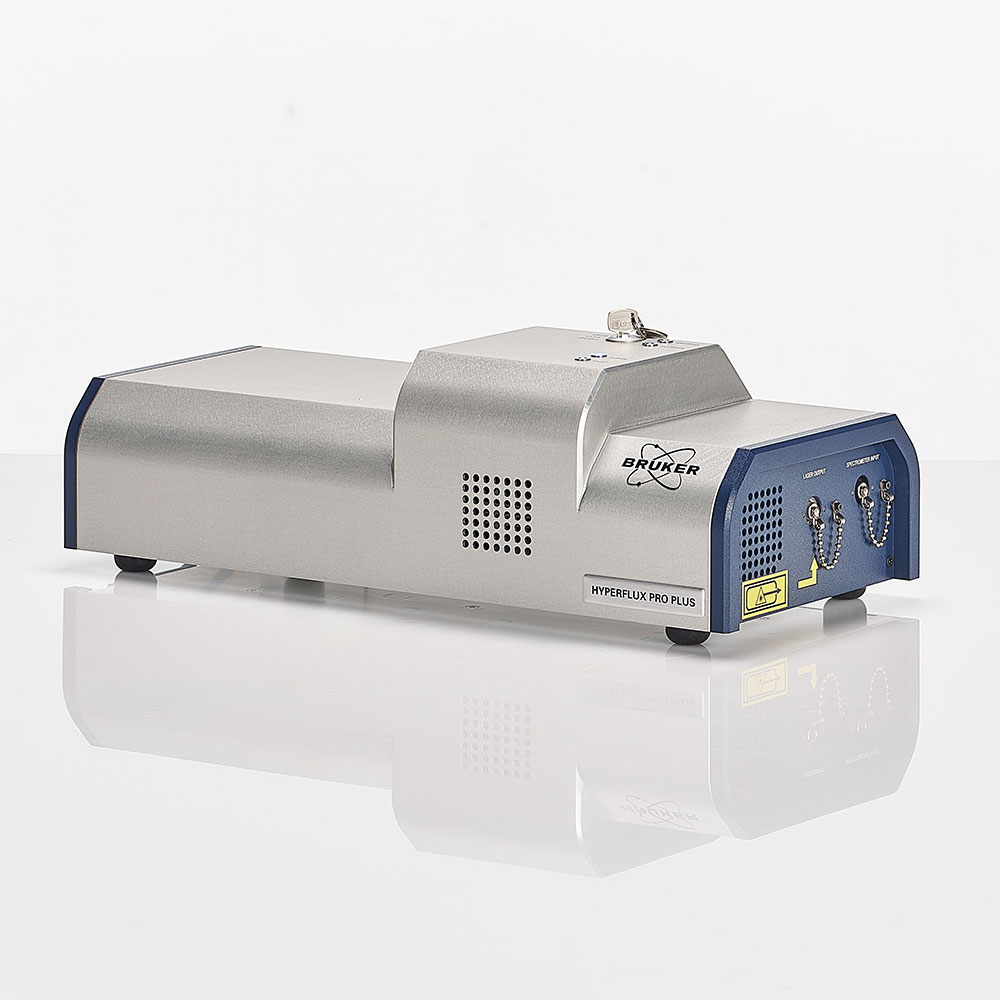

SuperFluxTM

Your Fit-For-Purpose Raman Analyzer

The SuperFlux™ Raman spectrometer delivers powerful performance in a compact benchtop form factor. Designed for laboratory-scale and light industrial process use, the SuperFlux™ combines speed, sensitivity, and affordability in a standalone analyzer that’s easy to deploy and operate.

Powered by Tornado’s proprietary High Throughput Virtual Slit (HTVS™) technology, SuperFlux™ achieves 10x to 30x higher Raman signal intensity than conventional slit-based spectrometers—enabling faster measurements, enhanced chemometric precision, and lower detection limits.

Whether you're doing QA/QC, R&D, or monitoring small-scale production, the SuperFlux™ is a reliable and cost-effective solution for real-time, non-destructive chemical analysis.

Key Features

- HTVS™ technology for industry-leading sensitivity and speed

- Compact benchtop design

- Embedded control system—no external PC required

- 785 nm laser

- Rugged construction with no moving parts

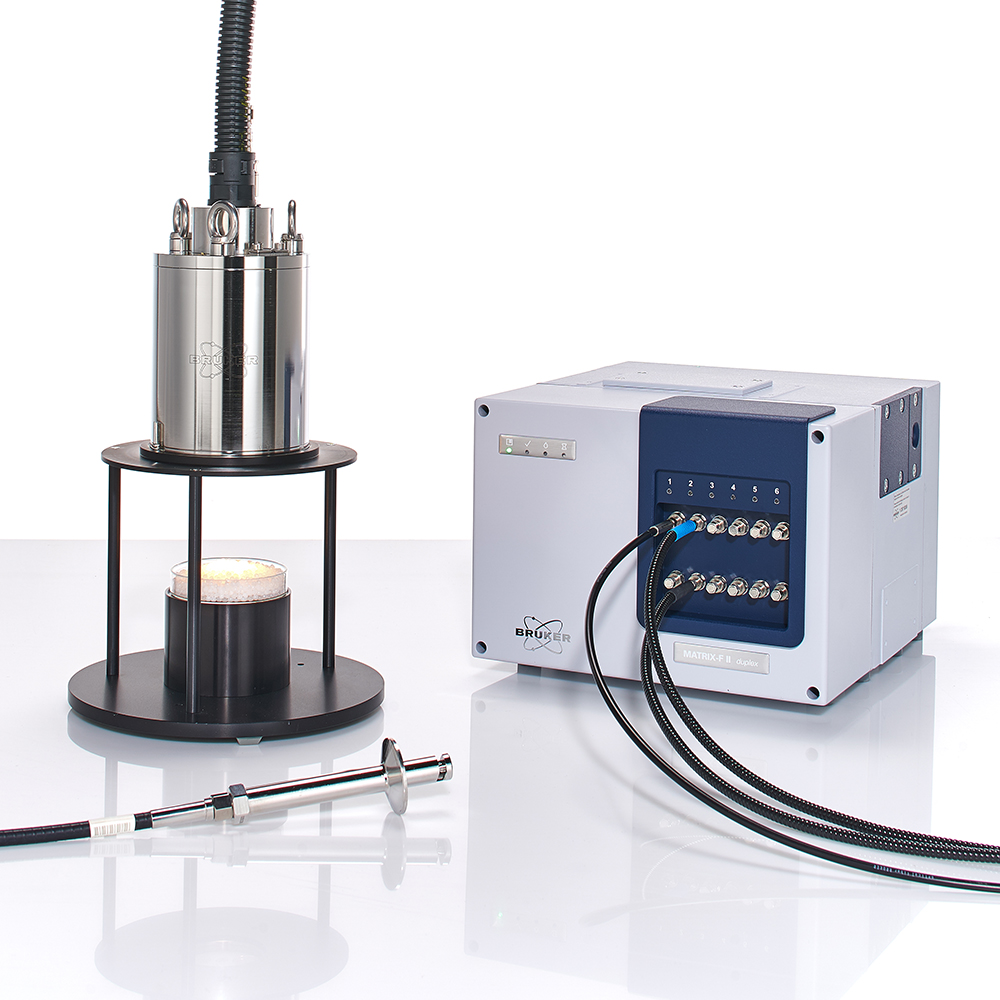

- Duplex fiber optic connectors with break detection

- Supports a wide range of Raman probes for diverse applications

- Remote operation via OPC UA client

- 21 CFR Part 11 compliant

Unmatched Sensitivity with HTVS™ Technology

At the heart of SuperFlux™ is Tornado’s patented High Throughput Virtual Slit (HTVS™) technology, which provides 10x to 30x higher signal intensity than traditional slit-based designs. This breakthrough enables faster measurements, improved signal-to-noise ratios, and lower detection limits—ideal for precise quantification and real-time process control.

Rugged, Reliable Operation

Engineered without moving parts, the SuperFlux™ ensures long-term durability and stable performance. Safety interlocks, break detection, and duplex fiber optic connectors further enhance reliability and ease of use in daily operation.

Compact, Standalone Design

SuperFlux™ delivers powerful Raman capabilities in a small benchtop footprint with an embedded control system—no external PC required. It’s easy to install, simple to operate, and fits seamlessly into any environment.

Applications

Large Molecules (Biologics)

SuperFlux™ is well suited for upstream and downstream bioprocess development and quality control. With its high sensitivity and non-destructive measurements, it enables real-time monitoring of critical quality attributes such as glucose and lactate during cell culture, and supports capture-phase and polishing steps in downstream workflows—all from a compact, easy-to-integrate analyzer.

Chemical

The SuperFlux™ enables real-time insight into chemical reactions and process development at the lab scale. Its high sensitivity allows users to monitor low-concentration species, track reaction kinetics, and measure impurities and residuals with confidence, supporting both research and pre-scale-up stages.

Food and Beverage

The SuperFlux™ supports food quality testing with real-time compositional analysis of oils, alcohols, sugars, and other key components. Its non-destructive approach and rapid measurement capabilities make it ideal for laboratory-based authenticity checks, contaminant screening, and formulation testing in food and beverage development

Small Molecules (Chemical Drugs)

From formulation development to QA/QC, SuperFlux™ provides fast, accurate chemical analysis of active pharmaceutical ingredients (APIs) and complex formulations. Its precision makes it ideal for monitoring crystallization processes, verifying blend uniformity, and supporting tablet coating studies in lab environments.

Polymers

With its ability to characterize both chemical and physical properties, SuperFlux™ is a valuable tool for polymer formulation and quality control. Users can monitor polymerization reactions, measure additive levels, and assess material properties such as density—all with fast, non-destructive analysis.