Process GuardianTM

Real-Time Process Monitoring with Uncompromised Precision

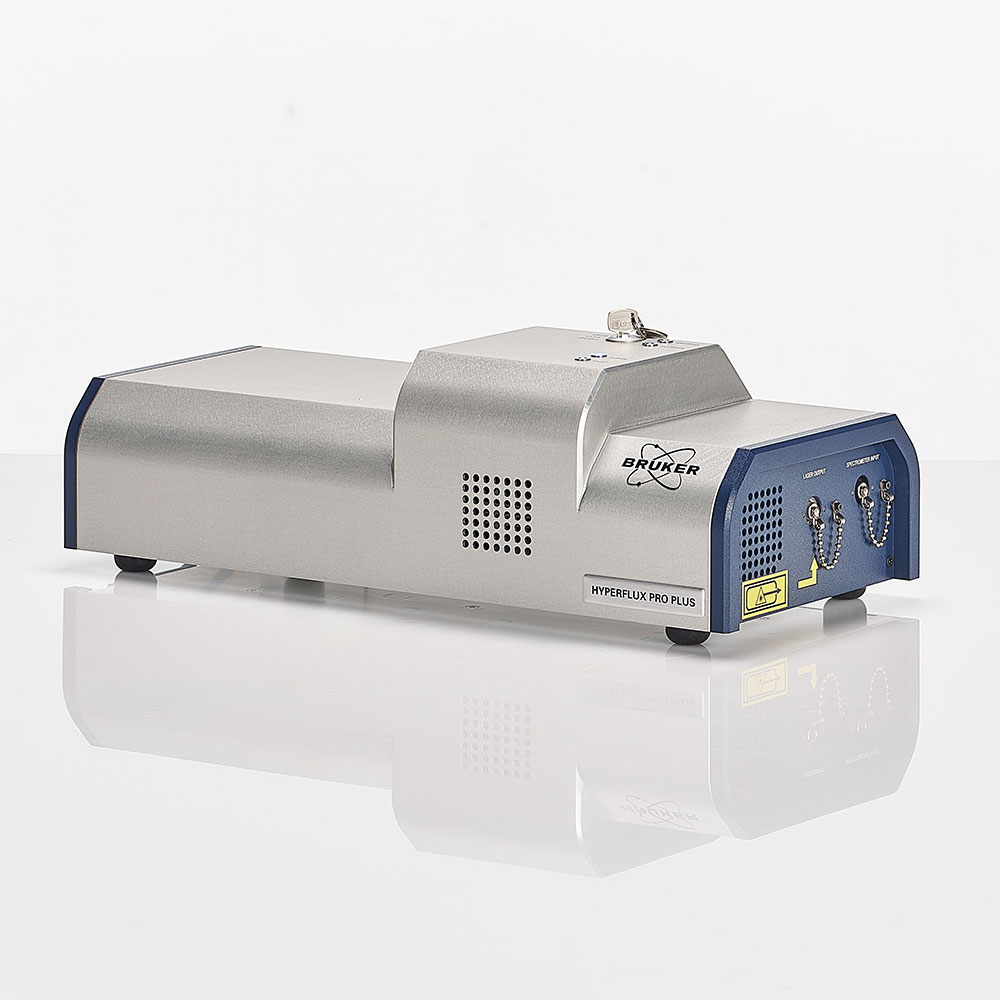

The Process Guardian™ Raman spectrometer is engineered to meet the evolving demands of modern process analytics. Built on our patented High Throughput Virtual Slit (HTVS™) technology, it delivers 10x–30x greater signal intensity than conventional slit-based Raman spectrometers—enabling faster measurements, lower detection limits, and greater chemometric accuracy.

Designed as a rugged, rack-mountable standalone analyzer, the Process Guardian™ simplifies deployment and operation in both development labs and industrial settings. With an integrated processor, embedded software, and built-in display, it operates independently—no external PC or IT maintenance required.

Whether used for in-line, at-line, or benchtop applications, the Process Guardian™ offers the performance, flexibility, and ease of use required for confident, real-time decision-making in critical processes.

Key Features

- HTVS™ technology for industry-leading sensitivity and speed

- Fully standalone design with embedded processor and software

- Field-replaceable 785 nm stabilized laser

- Intuitive control via rotary dial and glove-friendly buttons

- 8.7" integrated high-resolution display

- Dual LAN interfaces with OPC UA and Modbus TCP/IP support

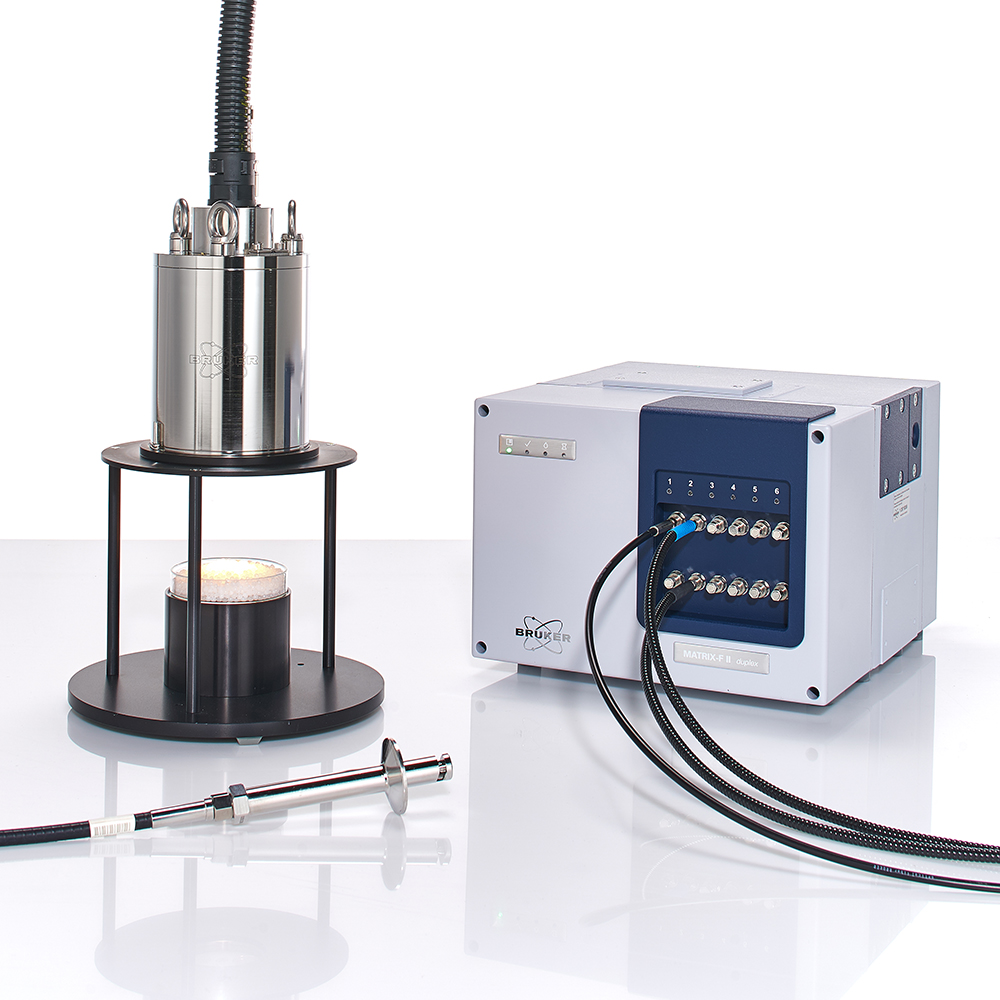

- Compatible with up to 8-channel fiber multiplexer

- Supports a wide range of Raman probes for diverse applications

- 21 CFR Part 11 compliant

- Available ATEX-certified configurations for hazardous zones

The HTVS™ Advantage

Our patented High Throughput Virtual Slit (HTVS™) technology is the core innovation behind the Process Guardian™'s superior analytical performance. By eliminating the optical slit of conventional spectrometers, HTVS™ dramatically increases photon throughput without compromising resolution. This results in up to 30x higher signal intensity, faster acquisition times, enhanced signal-to-noise ratios, and lower detection limits, even for low-concentration analytes or samples with strong background fluorescence.

Built for Hazardous Environments

The Process Guardian™ is available in configurations suitable for hazardous (Ex) zones, enabling safe and compliant operation in chemically or physically demanding industrial settings. When paired with the OPIS 35™ ATEX/IECEx certified laser accessory, the system supports intrinsically safe Raman measurements, expanding its usability in petrochemical, pharmaceutical, and other regulated sectors.

Optimized for Process Insight and Control

Combined with its fast acquisition speeds and advanced chemometric capabilities, the Process Guardian™ helps users gain enhanced process understanding and control, enabling real-time adjustments and long-term optimization. Whether in development or production, it empowers teams to make faster, smarter decisions based on high-quality Raman data.

With optional multiplexing support for 4 or 8 channels, a single analyzer can monitor multiple points across a process line—dramatically reducing equipment footprint and cost per measurement. This capability enables users to scale monitoring efforts, gain a more holistic view of their process, and accelerate deployment across development and production environments.

Simple Installation and Operation

The Process Guardian™ is purpose-built to thrive in demanding process environments, delivering actionable insight with minimal operational burden. Its fully embedded architecture means no external PC is required—simplifying installation, eliminating IT dependencies, and improving system uptime.

Operators benefit from an intuitive interface featuring durable hardware controls and a bright, glove-compatible display, while remote users can access key performance data 24/7 via standard industrial protocols. Integrated health monitoring, laser safety interlocks, and smart fault detection add layers of reliability and automation.

Applications

Large Molecules (Biologics)

The Process Guardian™ enables precise, real-time monitoring of both upstream and downstream biopharmaceutical processes. From tracking key nutrients like glucose and lactate in cell cultures to monitoring critical quality attributes (CQAs) across purification and formulation steps, it supports process optimization and control at every scale. Its high sensitivity and embedded intelligence make it ideal for continuous monitoring and digital bioprocessing strategies.

Chemicals

The Process Guardian™ excels in chemical manufacturing environments where real-time insights are critical. It provides fast, precise measurements of reaction progress, impurity levels, and residual reactants, even at low concentrations. With its robust design and process-ready software, it’s an ideal tool for supporting advanced kinetic studies and continuous manufacturing workflows.

Food and Beverage

For industrial food processing, the Process Guardian™ offers a rapid, non-destructive solution for compositional and structural analysis. It enables continuous monitoring of key quality indicators such as fat and sugar content, alcohol concentration, and food authenticity. Its precise molecular characterization helps improve process control, support regulatory compliance, and safeguard product integrity.

Small Molecules (Chemical Drugs)

Whether used for formulation development, process optimization, or production control, the Process Guardian™ delivers high-quality Raman data to support consistent drug quality and yield. Its multiplexing capabilities allow monitoring of multiple points simultaneously, enabling seamless analysis of crystallization, blending, and tablet coating processes—while meeting regulatory compliance for pharmaceutical manufacturing.

Oil and Gas

Designed for harsh and hazardous environments, the Process Guardian™ provides robust Raman analysis for petrochemical and refinery applications. It supports real-time quantification of olefins, aromatics, and benzene, as well as indirect property estimation such as octane rating and vapor pressure. Its gas-phase monitoring capabilities enable the detection and quantification of key components like hydrogen, hydrocarbons, and carbon dioxide.

Polymers

From development through manufacturing, the Process Guardian™ brings detailed chemical insight to polymer processes. It enables monitoring of polymerization reactions, detection of residual monomers, and analysis of additive content. With real-time feedback during extrusion or formulation, manufacturers can optimize product quality and maintain tight control over process variables.