ContourSP

ContourSP

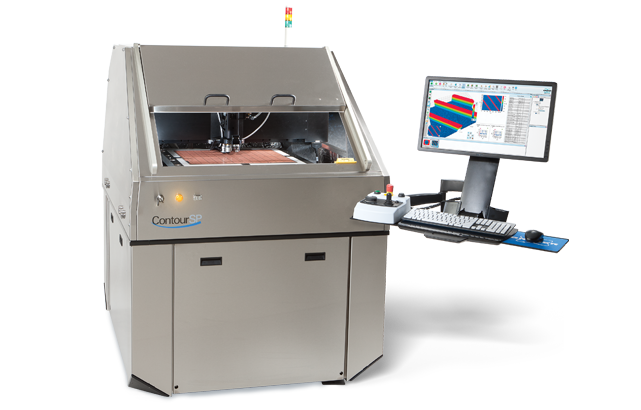

Incorporating over ten years of packaging optical characterization expertise, the ContourSP Large Panel Metrology System more than doubles the measurement throughput of high-density interconnect PCB (HDI-PCB) substrates over previous-generation WLI instruments. The system is specifically designed to measure each layer of the PCB panels during manufacturing, and incorporates a host of advanced features that deliver utmost production performance, convenience, reliability, and throughput for the semiconductor packaging industry. The gauge-capable ContourSP utilizes an intuitive production interface that offers fast and easy fiducial alignment with configurable user input.

Unmatched Accuracy

With its new vibration-tolerant system design and patented Wyko Vertical Scanning Interferometry (VSI) imaging, the gauge-capable ContourSP system performs extremely accurate 3D critical dimensional (CD) measurements in nanometer resolution. This ability combined with extensive automation allows ContourSP to multitask as both a powerful surface texture metrology instrument as well as an easy-to-use defect inspection tool.

Streamlined Operation and Analysis

The ContourSP intuitive production interface offers fast and easy fiducial alignment with configurable user input. In addition to pass/fail information, users can now select detailed parameter results for display on the summary screen. Vision64 software provides full access control for engineers, technicians and operators with easy coordinate file import capability, guaranteeing system-to-system recipe portability and fast file creation.

Large Measurable Area Tailored to Panel Metrology

The system utilizes Bruker's revolutionary gantry-based design and integrated workstation to support up to 600x600 millimeter samples in a highly compact footprint. Software designed specifically for production panel metrology helps manufacturing engineers and operators to take the fullest advantage of the unique optical profiling features with dynamic signal segmentation, remeasure functionality, topography scanning to compensate for wafer bow, coordinate file import, ESD, panel ID reading, and pattern recognition.