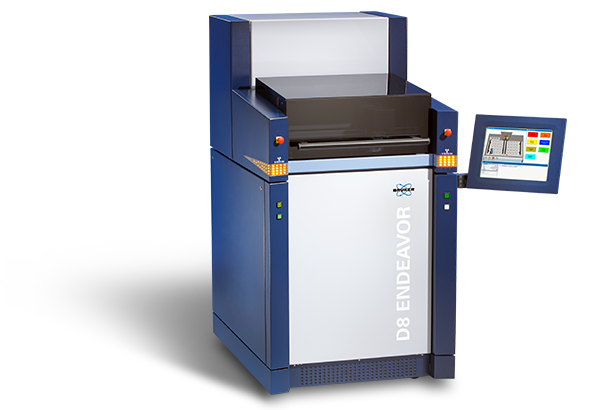

D8 ENDEAVOR

Automated X-ray Diffractometer

for high sample turnaround

Flexibility in Sample Handling

Powder XRD at all Conditions

The D8 ENDEAVOR is made for extremely simple operation, high measurement speed at lowest detection limits and fast sample turnaround. The system is well suited for multi-user operation in industry, academia and research. For industrial process optimization and quality control, the D8 ENDEAVOR can be interfaced to automated sample preparation systems, which feed the samples without further operator actions. This guarantees highest integrity, homogeneity and quality of sample preparation and presentation.

This analyzer easily fits all kinds of laboratory and environmental conditions

- 1 kW ECO version – low running costs by energy savings, single phase electricity, and no need for external cooling water

- 3 kW version – performance for those who desire lowest detection and quantification limits, or fastest measurement time

- Harsh environment option – highest reliability at high temperatures, humidity and in dusty atmospheres

- High altitude option – improved cooling and electrical safety for operation up to 4000 m above NN

The D8 ENDEAVOR, ready-to-use and capable of any circumstances.

Highest Performance – Lowest Operator Efforts

Not only is the D8 ENDEAVOR made for rough 24/7 operation. Under the hood you will find the finest Bruker XRD technology that is key for satisfying highest analytical demands.

- Dynamic Beam Optimization (DBO) – no instrument reconfiguration by the operator needed. Motorized optics optimally adapt the beam-path geometry to the measurement conditions needed for various materials

- LYNXEYE detectors – highest data quality and lowest quantification limits. The energy discriminating LYNXEYE XE-T detector exhibits unprecedented fluorescence and white beam residue suppression, high count rate capability paired with excellent angular resolution. And, there is no more need for secondary monochromators or primary Kß filters.

- Sample handling – High sample turnaround is achieved by unloading the previous and preloading the next sample while the current analysis is running. New samples can be put into the sample changer while the measurements are running without exposure of the operator to X-ray radiation.

Daily use of the D8 ENDEAVOR has the operator in mind and is not exclusive to the XRD expert.

- TouchControl and Loader – the intuitive and easy use reduces operator training to the absolute minimum. Just assign graphically the analytical method to a samples position shown in the loader software

- Push Button Templates – created by the lab manager or our experts they combine the entire workflow: loading the sample, adapting the instrument settings, performing the measurement, running an automated data evaluation, and finally presenting the analysis in the ResultsManager

Feature Gallery

Tailor made analytical solutions

Turn-key versions of the D8 ENDEAVOR are available for the cement, minerals, pharmaceutical, Aluminum, and metals industries.

They include:

- instrument configurations that are tailored to the specific requirements of those industries,

- optimized data acquisition and evaluation packages,

- industry specific application training and support.

Cement

XRD combined with TOPAS Rietveld analysis is nowadays the most powerful technique for doing quantitative phase analysis of hotmeal, bypass, kilndust, clinker and cements.

Combined with the XRD Method Package Cement the new D8 ENDEAVOR is the perfect solution for the industry.

It offers direct phase analysis along the entire production process, ranging from raw materials, intermediate products like hotmeal and dusts (REACH) to clinker and the finalized cements. Analytical highlights are the capability to distinguish the Alite polymorphs M1 & M3 and the quantification of amorphous phases by the proprietary PONKCS method.

Minerals

The most direct method of mineral identification and quantification is powder X-ray diffraction (XRD) with the D8 ENDEAVOR Minerals.

Complex geologic materials can reliably be analyzed using TOPAS quantitative analysis.

Furthermore, cluster analysis techniques can be used to quickly and automatically analyze large amounts of data for similarities and generate exploration mappings.

Metals

X-ray powder diffraction (XRD) is a widely used analytical method for the process and quality control of making steel.

Knowing the exact FeO concentration in the raw material is key to cut the greenhouse-gas emission of iron plants.

The FeO amount can directly be calculated from the stoichiometry and concentration of the minerals. These values determined by rapid XRD makes it a very fast alternative to titration.

Aluminum

Controlling aluminum production is a crucial analytical task that demands a robust X-ray diffraction (XRD) solution.

This is due to the harsh environment in a smelter, where the XRD instrument needs to be located, and the enormous sample throughput required to successively probe hundreds of smelter cells.

The D8 ENDEAVOR addresses these challenges with reliable mechanics and technological innovations that reduce measurement times and expand analysis capabilities.

Respirable Silica

The D8 ENDEAVOR is best suited to monitor lowest amounts of free silica, a material that causes lung cancer and other severe health issues.

Highest accuracy and a lowest detection limit are achieved with the D8 ENDEAVOR equipped with the LYNXEYE XE-T detector.

To complete the silica solution, Bruker offers sample holders for different filter types and a complete method for the DIFFRAC.DQUANT software, which is compliant with NIOSH 7500 requirements and also allow segment calibrations.

D8 ENDEAVOR Specifications

Specification | Benefit | |

Generator | 3 kW 1 kW ECO | Fastest scan time, lowest detection and quantification limits Low power consumption, single phase power, no external cooling water required |

Sample handling | Magazines with 66 samples 51.5 mm (2‘’) diameter or 72 samples with 40 mm (1.6’’) diameter EasyLoad trays for 20 samples of 2’’ diameter Robotic or conveyor belt loading | Industry standard sizes, compatible with automated sample preparation and automatization concepts Manuel loading of off-line prepared samples Automated instruments operation without operator interaction |

Beam optics | Dynamic Beam Optimization | Instrument adapts to optimal measurement conditions without manual reconfiguration. No expert knowledge required |

Motorized Anti-Scatter Screen | Reduced air scatter background for better peak to background ratio and improved limits of detection and quantification | |

Push button operation | Loader software and touch control | Instrument operation with only minimal training requirements |

Detectors | Proportional Ca XRF counter SSD160-2 LYNXEYE-2 LYNXEYE XE-T (*) Detector guarantee | Element channel for Al production control Si-strip detector with 160 channels Ultra fast 1D detector (*) Ultra sensitive, energy dispersive 1D detector (*) absolutely faultless, no dead strips |

Goniometer | Theta/Theta | Sample always horizontal and cannot fall off during measurement Unique alignment guarantee of +/- 0.01° 2Theta over the entire angular range, based on the always included NIST Standard Reference Material (SRM) 1976 |

Safety | German type approval CE Compliance | Highest standards for operator safety Machinery Directive (2006/42/EC), Electrical Equipment (2014/35/EU) Electromagnetic compatibility (2014/30/EU) |

D8 ENDEAVOR Specimen Holders

Sample preparation efforts for the D8 ENDEAVOR are minimal, as a wide range of sample sizes and types can be handled simultaneously. The gripper that loads the specimen holders from the magazine to the measurement position automatically detects different heights of specimen holders.

- Specimen holders have industry standard diameters of 51.5 mm (2’’) or 40 mm (1.6‘’)

- Fine grained powder is filled into sample holder cavities of various diameter or depth matching the sample amount.

- Back-loading is available to reduce preferred orientation.

- Very small amounts of powder can be prepared on background-free holders.

- Specialized holders for filters, clays, solids, and environmentally sensitive samples are further options of a broad choice.

Measurement and Analysis Software

The full-featured, and no compromise DIFFRAC.SUITE software package provides the easiest measurement method creation and most powerful and accurate analysis results. All covered with 21CFR Part11 compliance, if required. The DIFFRAC.SUITE MEASUREMENT CENTER, DIFFRAC.EVA for general data evaluation and cluster analysis, but also the COD database for phase identification are always included with two licenses for industrial laboratories and 10 licenses for academic users. Additional licenses are optionally available. DIFFRAC.TOPAS is used for the quantification of complex multi-phase mixture, whereas DIFFRAC.DQUANT offers norm compliant analysis for the industry that are based on calibrations, and therefore most precise.

For industrial process and quality control the D8 ENDEAVOR can be equipped with TOPAS BBQ for automated Black Box Quantification. Also we offer the Bruker turn-key package for the analysis of construction materials that comes with 10 ready-to-run methods that are prepared by our Cement application specialists. The DIFFRAC.SUITE software may be operated in file or database mode and includes a RESULTS MANAGER for multi-sample reporting and time series representations.

D8 ENDEAVOR Resources

Brochures & Lab Reports

Spec Sheets & Flyers

Service & Support

- Helpdesk for technical issues with hardware, software, and applications support using web based and advanced remote service tools.

- LabScape Maintenance Service Agreements

- On-site, on-demand support

- Installation and operational qualification as well as performance verification

- Site planning, relocation, and consultation

- Replacement and spare parts, consumables, and in-person and online training

- Software updates, manuals, and LabScape MSA management (↗brukersupport.com)