Assessing the Surface Metrology of Orthopaedic Implants

Explore surface texture analysis methods to improve performance of orthopaedic implants

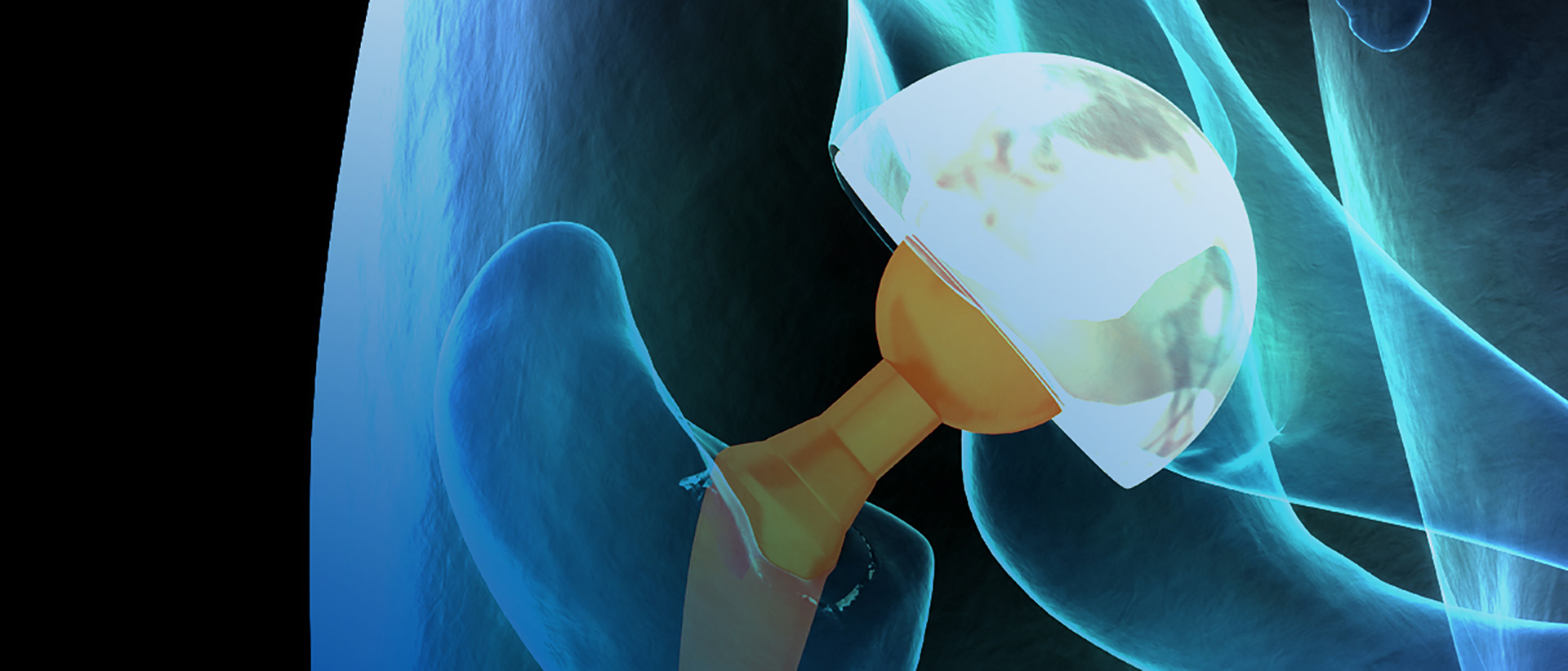

In orthopaedics, around 90% of failures are surface-related. Guest speaker, Prof. Liam Blunt, Director of the Centre for Precision Technologies at the University of Huddersfield, uses case studies to illustrate how analyzing and optimizing surface texture of orthopaedic implants can improve their performance.

This webinar also includes a practical session on the NPFLEX optical profiler, demonstrating:

- Non-contact and non-destructive characterization of surface parameters;

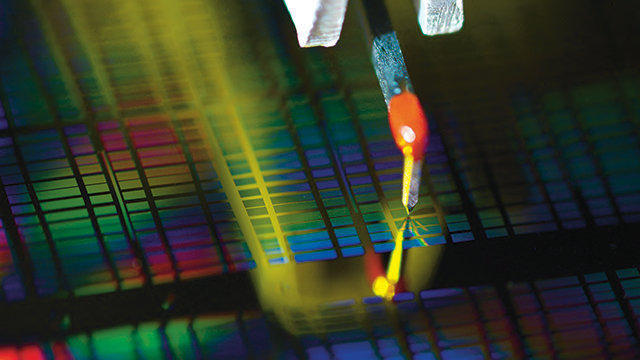

- 3D optical microscopy measurements based on white light interferometry;

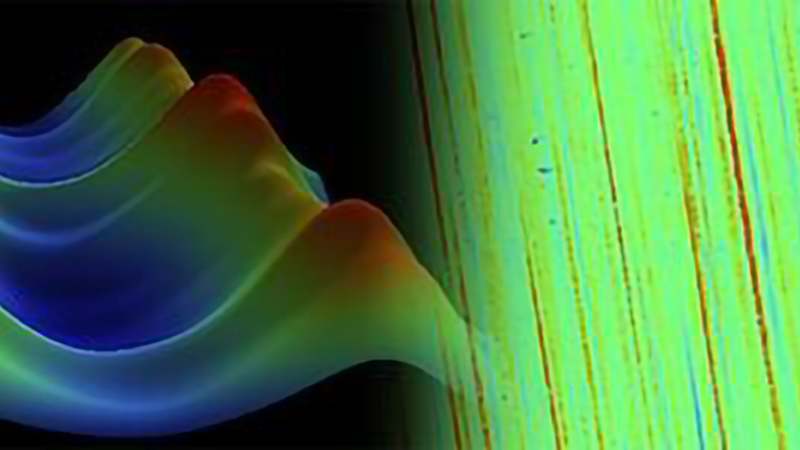

- Quantification of curvature variations; and

- Calculation of loss of volume.

Surface Metrology for the Orthopaedic Applications;

Measuring the Rough with the Smooth

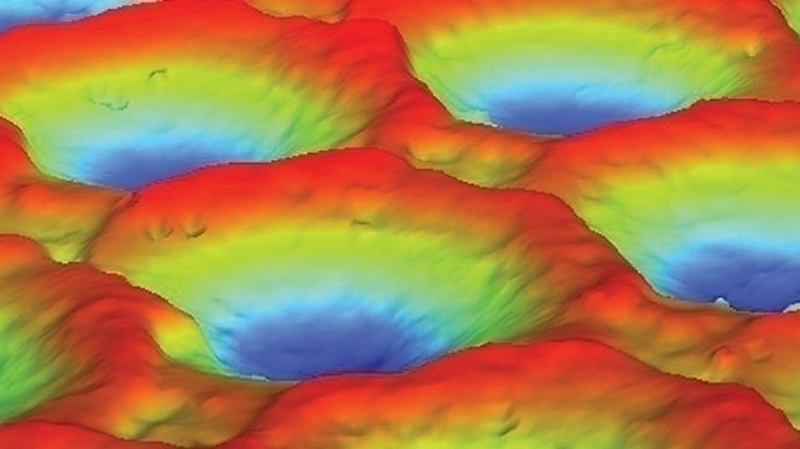

Guest speaker, Prof. Liam Blunt, Director of the Centre for Precision Technologies at the University of Huddersfield, presents a series of case studies to illustrate how areal roughness parameters can be used to optimize analysis of the data collected and give clues about the quality, performance, and overall functionality of materials and products used in orthopaedic implants.

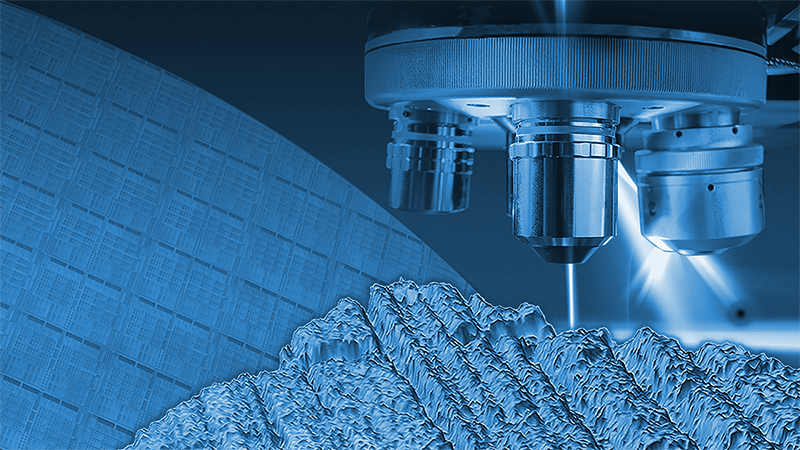

Blunt reviews the application of precision surface metrology to a range of orthopaedic implant and device materials and provides practical guidance regarding the ideal selection of particular instruments for particular applications. He discusses surfaces ranging from precision-polished bearing surfaces to those of additively manufactured parts. In these cases, selection of the most appropriate instrument is considered along with coherence scanning interferometry and focus variation technologies.

After Prof. Blunt’s presentation, Udo Volz from Bruker demonstrates optical profilometry on the NPFLEX system. He measures a hip implant's roughness and shows volume analysis of a worn ball.

Find out more about the technology featured in this webinar or our other solutions for surface roughness measurement:

Speakers

Liam Blunt, Ph.D.

Professor, Department of Engineering and Technology, School of Computing and Engineering; Director, Centre for Precision Technologies

University of HuddersfieldProfessor Liam Blunt has an honours degree in Materials Technology and a Ph.D. in "The Metallurgy of CentrelessGround Surfaces" under the supervision of Dr. Wilf Tomlinson at Coventry University. Prof Blunt also spent one year working as a metallurgist in failure analysis at AMTAC Laboratories in Manchester. His Academic experience includes a Post-Doctoral period at Warwick University covering Microscopy of Thick and Thin Film Superconductors. Prof Blunt then moved onto Birmingham University in 1990 to work on the development of a multi properties materials tester. Whilst at Birmingham he developed an interest in tribology and surface metrology. He secured a lectureship and developed his research in the field of surface metrology.

In 1997 Prof Blunt moved to Huddersfield and began developing the Centre for Precision Technologies. As well as teaching in the area of Materials and Manufacturing processes, he has formed extensive industrial collaborations and is now Director of the Centre for Precision Engineering. His Research expertise and interests are: Surface micro and nano metrology, tribology and metrology for medical implants, development of precision abrasive processes, and forensic metrology for ballistics.

Udo Volz, Ph.D.

Applications Engineer, Bruker EMEA