In-Situ SEM Nanomechanics of Metals and Ceramics at Elevated Temperatures

Understand the deformation mechanisms of metallic and ceramic materials via in situ micromechanical testing under extreme conditions.

In this webinar, guest speaker Dr. Xinghang Zhang (Purdue University) showcases PI 89 capabilities on CoAl intermetallics, TiO₂, and nanotwinned aluminum, where many interesting deformation phenomena can be observed. A live demonstration of high‑temperature mapping with the PI 89 is also being presented by Bruker experts, along with analysis using Bruker’s Tribo iQ software.

Webinar Summary

This webinar, moderated by Bruker NI Sales Manager Michael Berg, has three parts: guest speaker, product overview, and live demonstration. Prof. Xinghang Zhang (Purdue University) first uses examples from his own research to showcase the in-situ and high-temperature capabilities of the PI 89, Bruker’s versatile SEM in-situ nanomechanical testing instrument. Second, Bruker Applications Scientist Eric Hintsala, Ph.D. briefly presents an overview of the PI 89 product features, capabilities, and accessories. Finally, Bruker Applications Scientist Jasmine Johnson gives a live demonstration of mapping using the PI 89, along with analysis using Bruker’s Tribo iQTM software.

Guest speaker Prof. Zhang focuses on three materials, examining their plasticity and deformability at high temperatures: nano-twinned Al alloys, nanocrystalline CoAl, and flash-sintered TiO2.

- In a process of Al alloy development, Prof. Zhang proceeds from binary Al-Fe to ternary Al-Fe-Ti. Using high-temperature micropillar compression in the SEM, Zhang’s group determined that adding Fe strengthened but softened the alloy, while adding Ti raised the recrystallization temperature and extended thermal stability.

- Nanocrystalline CoAl is typically very brittle due to its limited number of slip systems. By shifting the composition from Co50Al50 to Co60Al40, Zhang’s group found that a Co-rich shell developed, rendering the material not quite as strong but also a great deal less brittle.

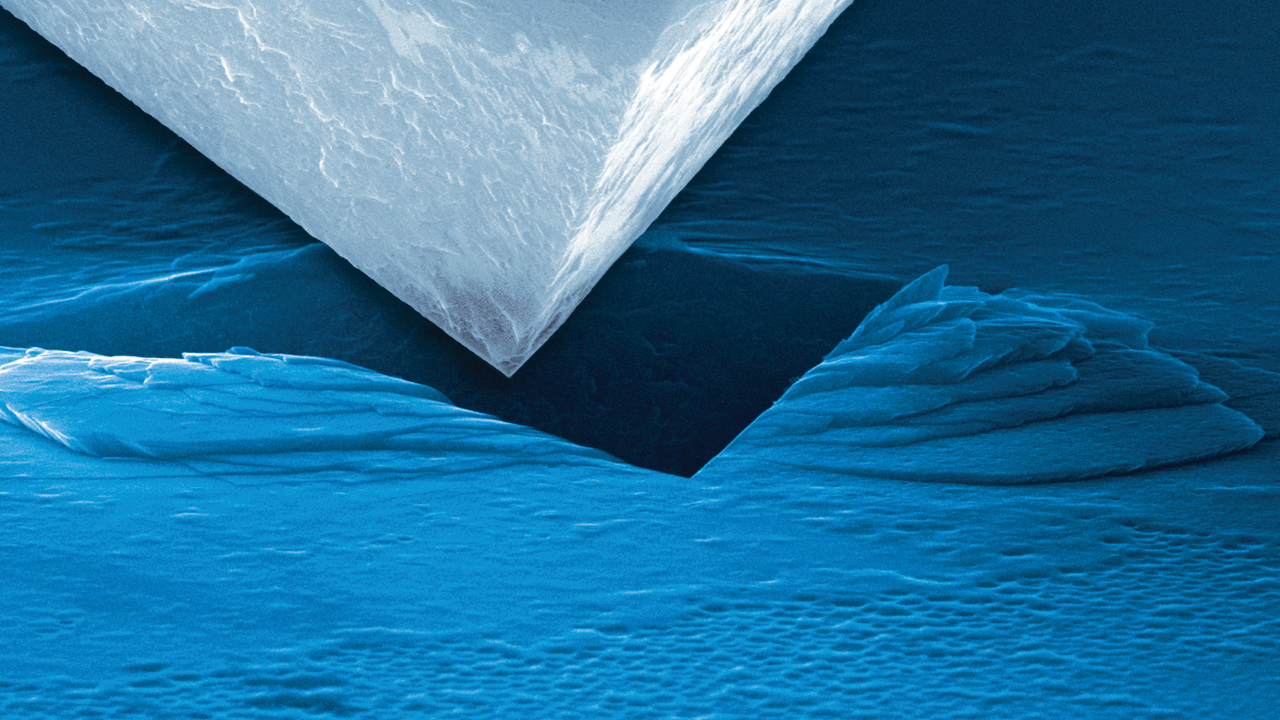

- Flash sintering is an extremely fast densification method that produces dense microstructures. When TiO2 was flash-sintered, Zhang and his co-authors discovered that its microstructure contained an abnormally high number of dislocations, increasing plastic deformation. Though by slightly different mechanisms, this flash-sintered TiO2 microstructure showed high levels of plastic deformation both at room temperature and at elevated temperatures.

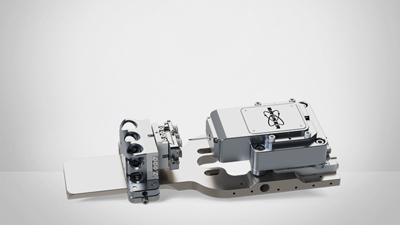

Connecting to the use cases presented by Prof. Zhang, Bruker’s Dr. Eric Hintsala explains why the PI 89 is both advanced and versatile, with a modular stage design, increased force range, multi-sample mounting, and quick-swap transducers. He also gives an overview of the many options and accessories available for the PI 89, all of which can be found on the Accessories tab of the PI 89 product page.

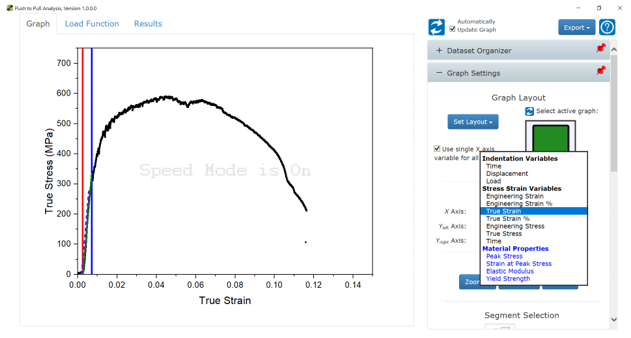

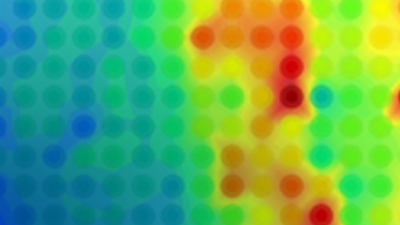

Bruker’s Jasmine Johnson finishes out the webinar with a testing and analysis demonstration. Johnson sets up an automated property map (60 indents in 12 minutes) at 600°C on a bond coating between nickel-aluminum and a nickel superalloy using the relevant control software:

- TriboTC for temperature control

- TriboScan for indenter control

She also analyzes equivalent data in the Tribo iQ software, which is an app in OriginPro. Among the TriboIQ capabilities are data corrections and performing a power-law fit for each indent to obtain parameters such as hardness and elastic modulus. Johnson plots and analyzes the data for the indent array in Tribo iQ XPM, showing several different plot views and filters, as well as quantitative analyses.

Find out more about the technology featured in this webinar or our other solutions for high temperature nano/micro-mechanical testing:

Featured Products and Technology

Speakers

Xinghang Zhang, Ph.D., Professor of Materials Engineering, Purdue University

Xinghang Zhang obtained his Ph.D. from North Carolina State University in 2001. He was a Director’s postdoc fellow at Los Alamos National Laboratory. After spending 12 years at Texas A&M University, he joined Purdue University in 2016. Zhang’s team excels at radiation damage and mechanical behavior of nanocrystalline, nanotwinned, and nanolayered metals and nanostructured ceramic materials. Together with his graduate students and colleagues, they have published more than 300 journal articles. Among more than 20 of his Ph.D. students graduated so far, many have become faculty at university or national laboratories. He is the Chair of the Nanomechanical Behavior of Materials Committee at the TMS, and an associate editor for Science Advances. Zhang has received numerous research awards, including National Science Foundation’s Early Career award and TMS Brimacombe medal. Zhang is an ASM Fellow.

Dr. Eric Hintsala

Applications Scientist

Dr. Eric Hintsala is a Materials Scientist, with a B.S. from Michigan Technological University and Ph.D. from the University of Minnesota. Dr. Hintsala's background is in mechanical properties of materials, nanomechanical testing techniques, and electron microscopy. Dr. Hintsala is part of R&D at Bruker NI, where he develops advanced instrumentation and testing techniques. Topics of particular interest include in situ testing, elevated temperature “in operando” testing and high speed nanoindentation mapping.