Qualifying Surface and Device Performance Through Roughness Quantification

Surface roughness measurement is a key process optimization tool.

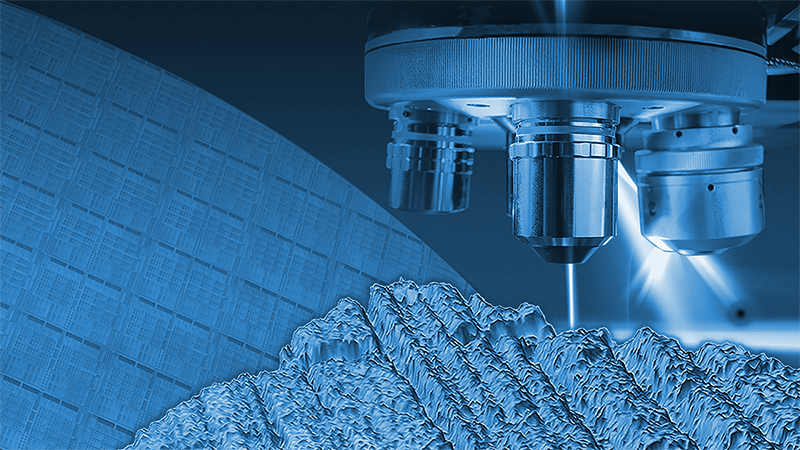

This webinar focuses on the use of non-contact optical profilometers and related analyses to accurately measure micro-roughness of surfaces, rank materials, and assess (and improve) product design efficiency and performance.

Webinar Summary

Better understand the full functional importance of surface texture parameters

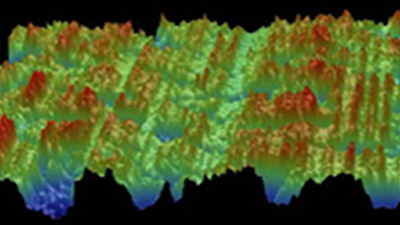

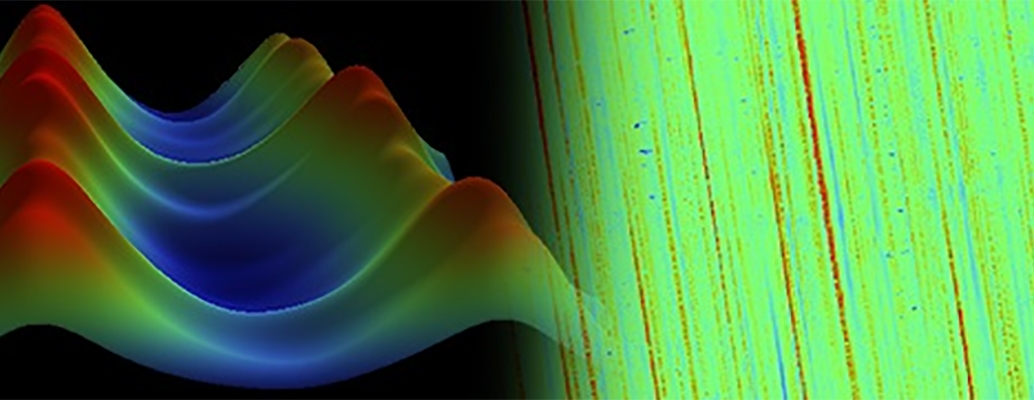

The 3D areal surface texture analyses made possible by advanced optical profilometry techniques are ideally suited for more than just quantitative defect detection and correction; mean roughness and other areal roughness parameters can be used to differentiate surfaces and quantify their efficiency for intended applications.

Geared toward scientists and engineers interested in characterizing the metrology, tribology, and surface-related performance of materials and devices — particularly those working in R&D or process and quality control — this webinar explains:

- How and when to use areal (instead of profile) measurement methods given the intended application;

- The benefits of data analysis using the 3D international standard ISO 25178 norm;

- How these analyses can be exploited to rank surface properties and explain wear processes; and

- 3D optical profilometry as a method of correlating micro-roughness to surface and device efficiency.

The presentation includes case studies from the automotive, sensors, optics, and medical industries.

This webinar was presented on June 17, 2019.

Find out more about the technology featured in this webinar or our other solutions for surface roughness quantification:

Featured Products and Technology

Speakers

Samuel Lesko, Ph.D.

Dir. of Technology and Apps Development for Tribology, Stylus & Optical Profilers, Bruker

Samuel Lesko has over 20 years of optical and stylus profiler applications experience, particularly in using white-light interferometry in a wide variety of fields, from MEMS and semiconductor to automotive and aerospace. He is a member of SME and part of ISO/TC 213/WG committee (areal roughness) and obtained his physics Ph.D. and material science engineering degree at the University of Burgundy in France.