PAT Solutions

Optimize your manufacturing by implementing modern Process Analytical Technology

Process analytical technology (PAT) is defined by the United States Food and Drug Administration (FDA) as a system for designing, analyzing, and controlling pharmaceutical and biopharmaceutical manufacturing processes through the measurement of Critical Process Parameters (CPP), which affect Critical Quality Attributes (CQA).

PAT initiative is an effort to facilitate the introduction of new technologies into manufacturing in the pharmaceutical industry. Today's competitive industrial environment requires drug manufacturing that continuously strives to improve product quality while reducing production costs. The goal of PAT is to enhance understanding and control this manufacturing process, which is consistent with the FDA's current drug quality system: quality cannot be tested into products; it should be built-in or should be by design (QBD).

In routine manufacturing, PAT enables continuous and real-time quality assurance (QA) to ensure consistently high product quality and performance, batch after batch. Structured product and process development, using experimental design and on or in-line process analyzers to collect data in real-time, can provide increased insight and understanding for process development, optimization, scale-up, technology transfer, and control. Process understanding then continues in the production phase when other variables (e.g., environmental and supplier changes) may possibly be encountered. Therefore, continuous learning over the life cycle of a product and applying those learnings is important.

PAT offers the pharmaceutical industry a framework for revolutionizing its R&D and manufacturing businesses, to produce value for both themselves and patients. The main benefits associated with PAT for companies include:

- Reduced waste, right-first-time manufacturing, higher production asset utilization

- Real-time quality assurance and validation

- Increased movement toward a real-time product release

- Reduced raw material, work-in-progress, and finished goods inventories by lean manufacturing processes

- Increased robust product supply to the public

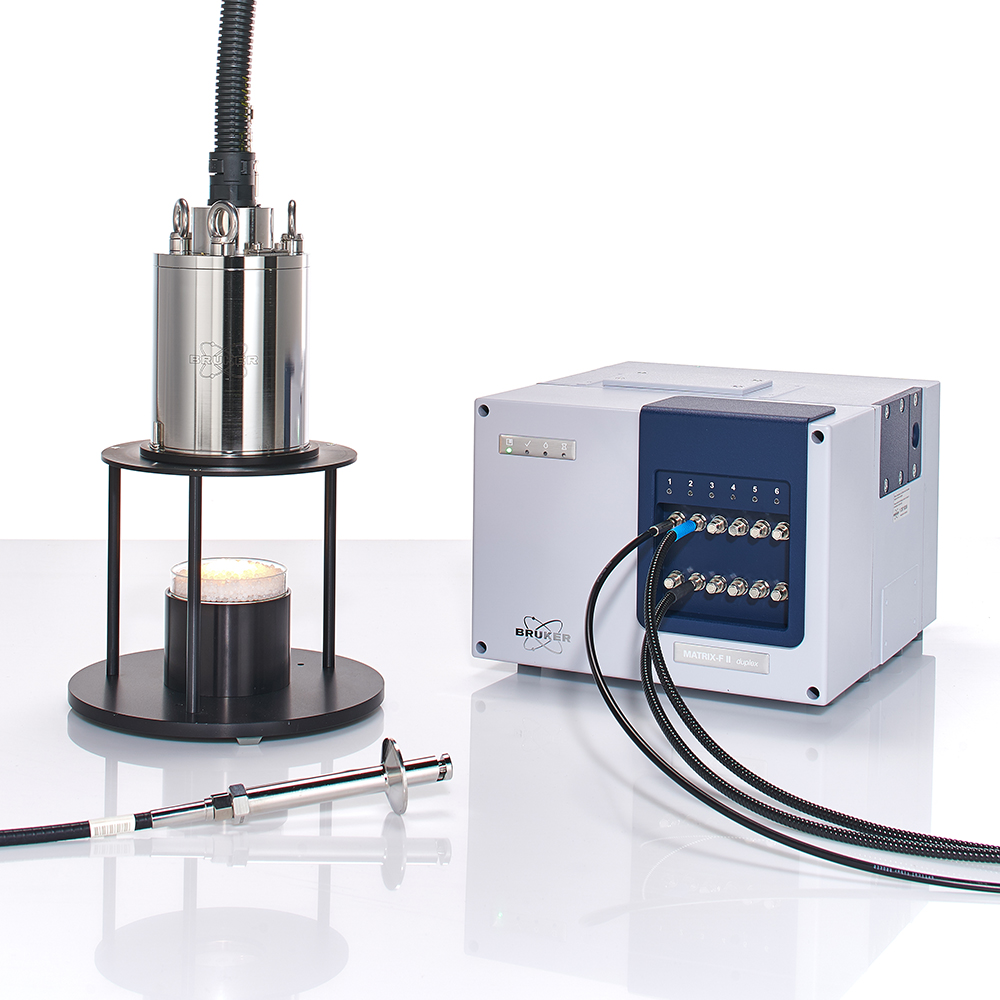

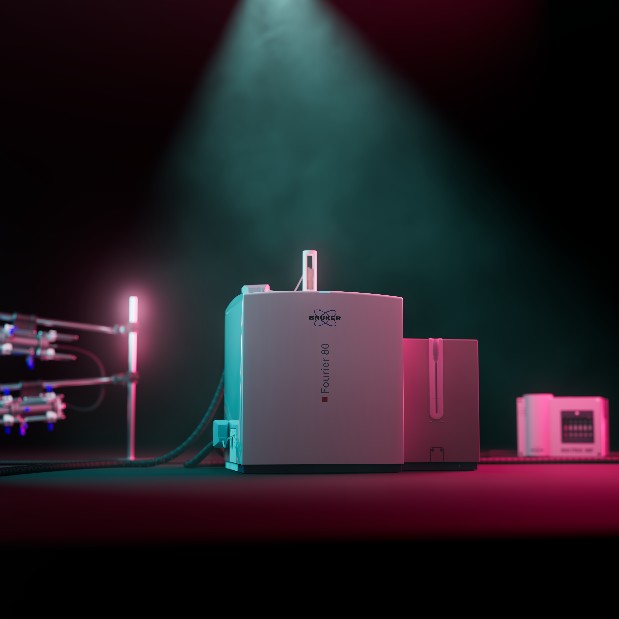

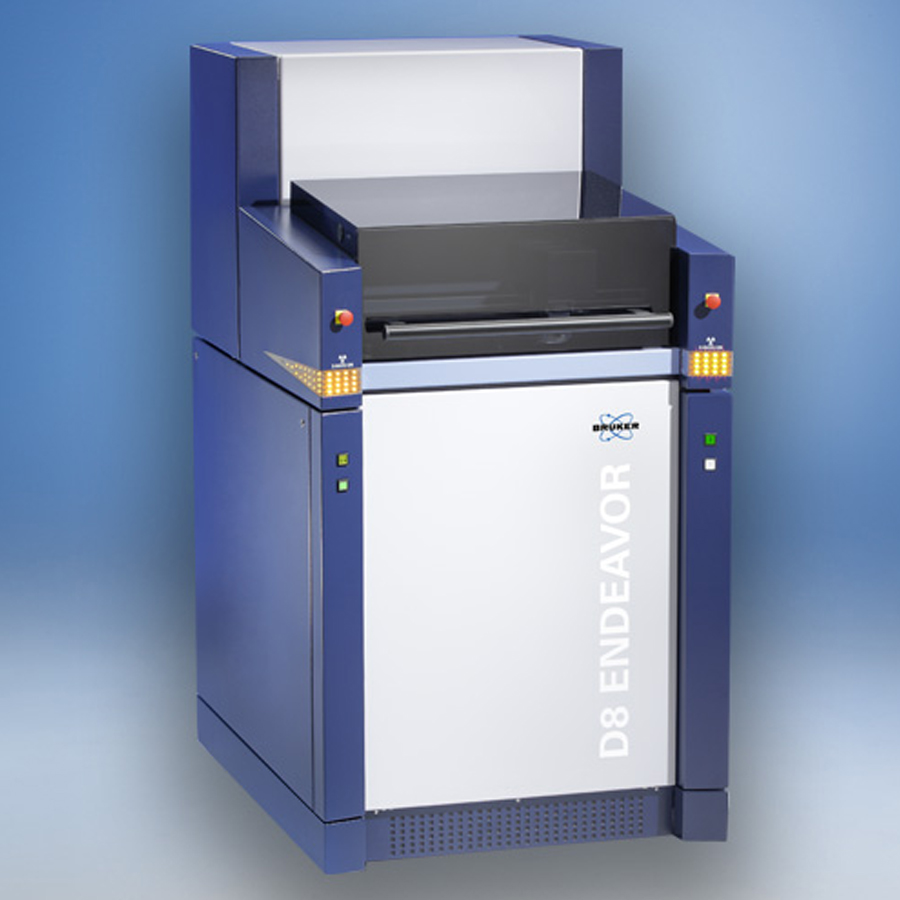

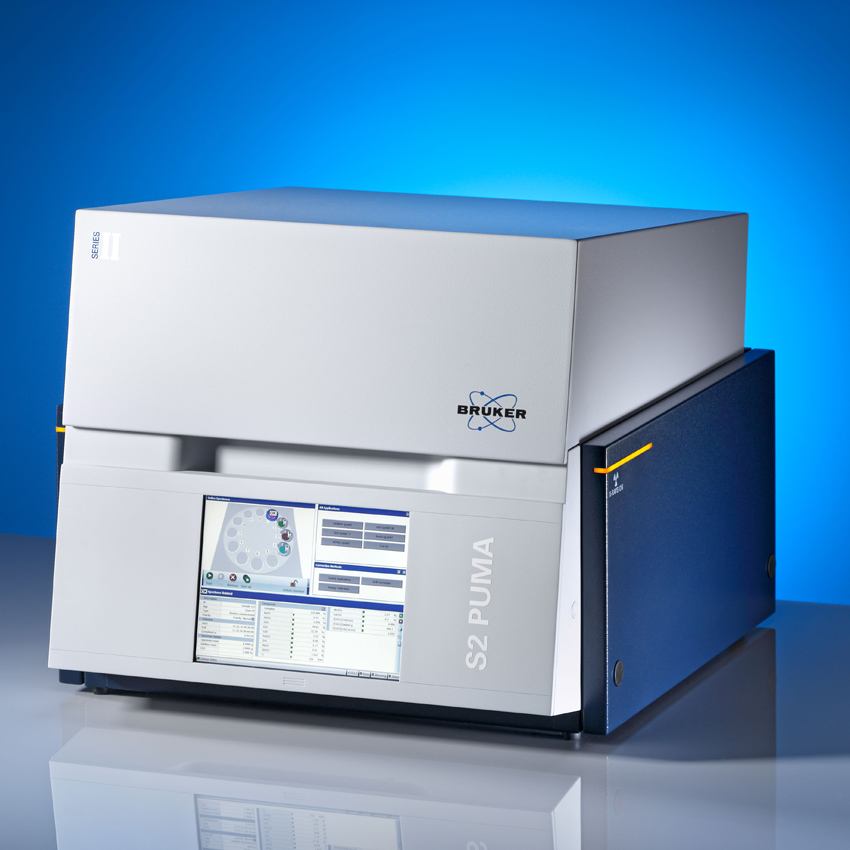

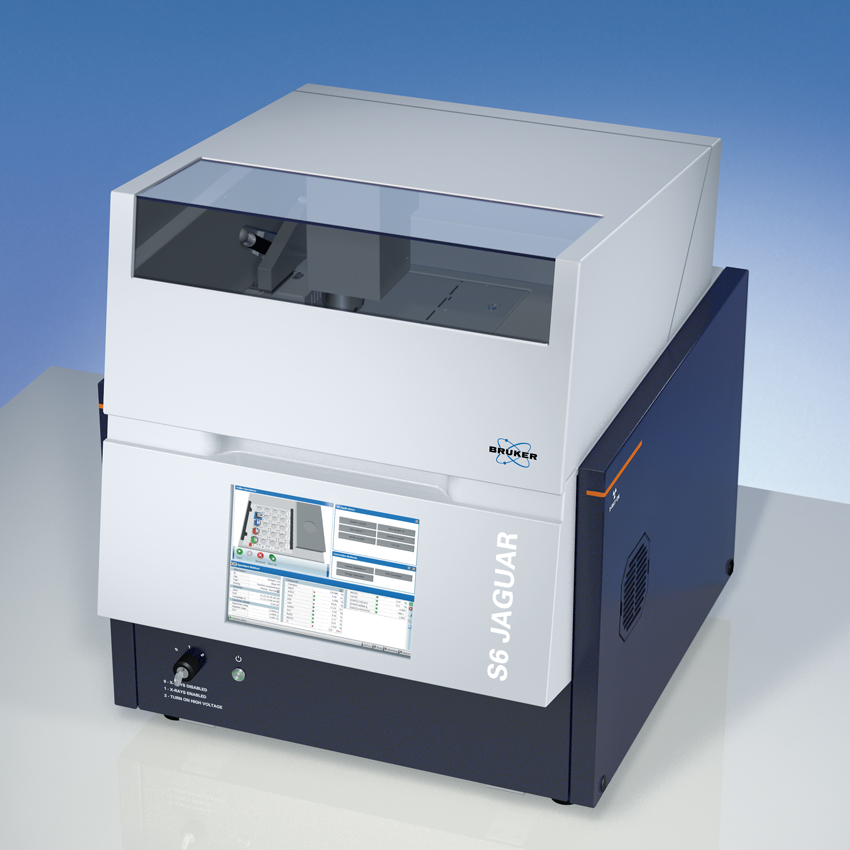

Bruker offers a range of tools for PAT: namely PAT management software synTQ, NMR, FT-NIR, Raman spectroscopy, XRD, and XRF spectrometry. NMR for PAT is independent of the sample matrix, needs no calibration, and can deliver data quickly and frequently. NIR, FT-NIR, and Raman provide a comprehensive range of PAT solutions based on vibrational spectroscopy. XRD is particularly suited to detect and anticipate form changes that may occur and adversely affect drug substance quality. XRF allows for rapid and accurate quantification of elemental impurities, providing immediate feedback.

Free eBook:

‘QbD & PAT for Dummies’ offers a simple and easy to follow guide on what Quality by Design (QbD) and PAT are, the regulatory framework supporting these approaches, as well as how leveraging these concepts can positively transform production processes and quality testing.

Get in touch to get the book:

Related Products

Fourier RxnLab

Online monitoring of chemical and bioprocesses by benchtop NMR, in real-time, under process conditions.

Support

Service and Life Cycle Support

Bruker’s commitment to provide customers with unparalleled help throughout the buying cycle, from initial inquiry to evaluation, installation, and the lifetime of the instrument is now characterized by the LabScape service concept.

LabScape Maintenance Agreements, On-Site On-Demand and Enhance Your Lab are designed to offer a new approach to maintenance and service for the modern laboratory