FT-NIR for Beverage Analysis

High-quality raw materials are the base of prime beverages. FT-NIR can help to evaluate incoming goods and assist production by monitoring and controlling processes, e.g. the fermentation of must or wort. Also, ensuring a tight specification for a wide product variety can be easily achieved with such fast analyzers.

Many of the raw materials used for producing beverages can be analyzed by NIR. From solid samples like wheat, barley, malt, hops and yeasts to liquids like concentrates. A special raw material is grapes which can be measured with the right sample preparation.

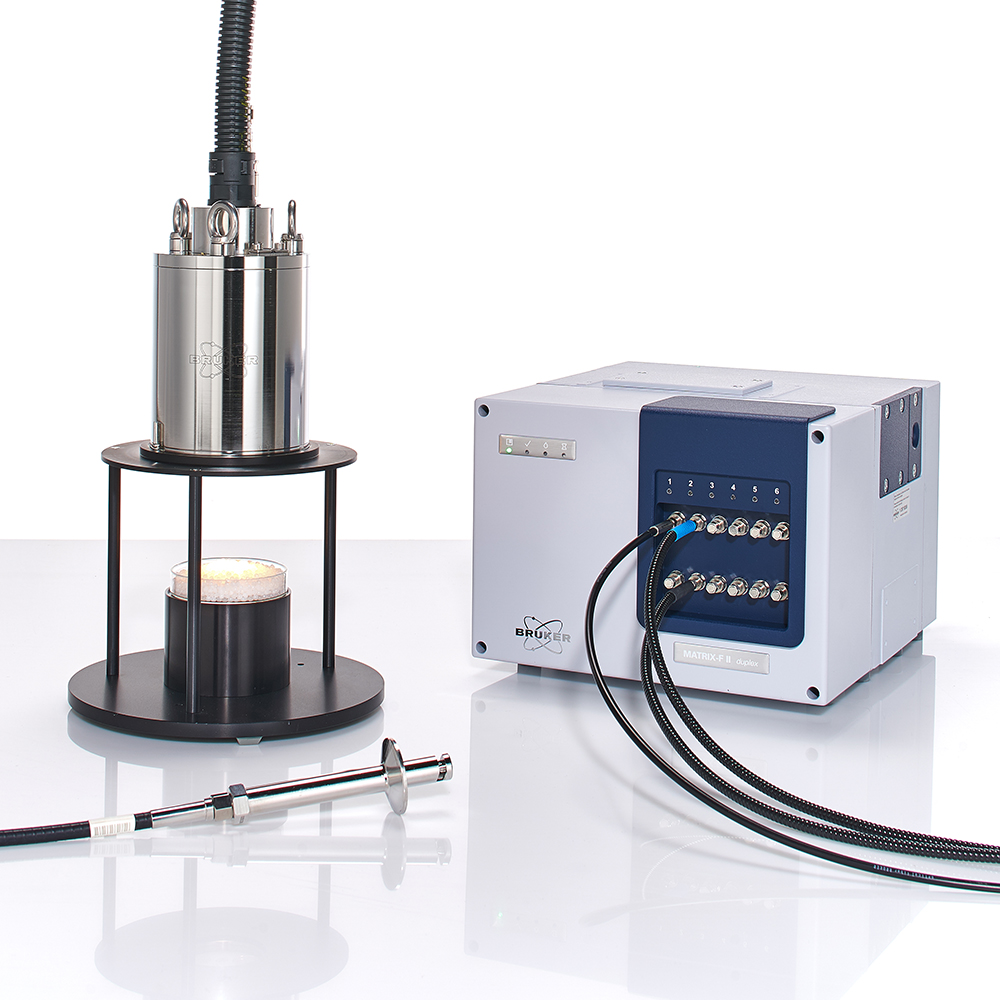

Most intermediates and products are liquids and analyzed in transmission through a maintenance free quartz flow cell with 1mm (1,000μm) path length that does not show cuvette wear over time. Adding the Liquids Sampling Module (LSM) to a MPA II spectrometer automates the whole process of analyzing and cleaning for highest reproducibility and accuracy.

Application Areas

Distillery and other spirit production processes are ideal for NIR analysis since most compounds are organic and at sufficiently high concentration. From unloading the grains off the truck, to the final bottling,

NIR analysis can provide useful information for process control. Especially fermentation optimization can be complex to reach the targeted alcohol content and optimum yield. Here and during distillation NIR is fast tool to gain required information and allow correction of potential problems.

These popular beverages cover a wide range from a liquid up to smoothies or even a fruit puree texture. Depending on the viscosity and insoluble dry matter content, e.g. pulp in fresh juices, a measurement is done temperature controlled in transmission or alternatively in transflectance. Common parameters of interest are e.g. Brix, density, acidity, citric acid and vitamin C content.

Milk alternatives are today very important for several reasons like avoiding animal products or lactose intolerances. From the analytical point of view milk made from soya, almonds, rice, hemp, cashew, oat or coconut can be analyzed like cow milk in terms of handling using different calibrations. Main parameters are protein, fat, total sugars and density.

The transmission analysis in the 1mm flow cell is independent of fat content and globule size distribution.

Coffee beans are analyzed by NIR as green beans and finally roasted to varying degrees, depending on the desired flavor. Protein and fat content as well as more relevant parameters like total acidity, moisture and caffeine can be determined. Low caffeine content can be analyzed accurate enough to control the de-caffeinated coffee to ensure that a certain minimum content guaranteed.

Similar applications are used to control the caffeine content in de-caffeinated tea which is moreover tested for moisture and parameters like polyphenols to monitor the fermentation process.