Direct-Pull-Tensile Tests

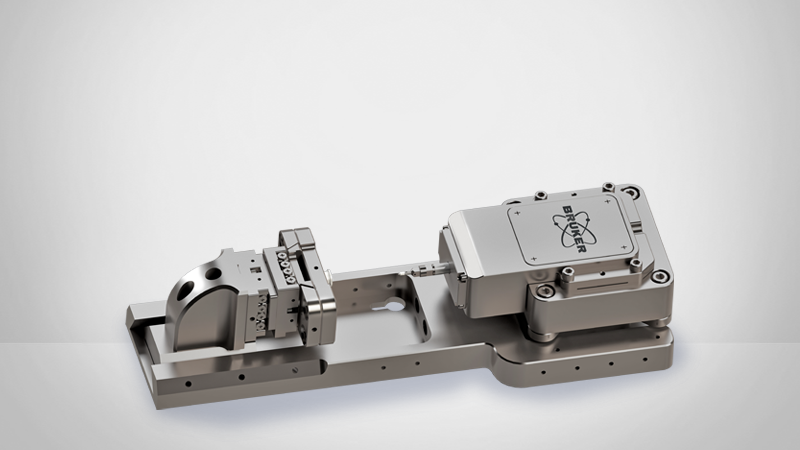

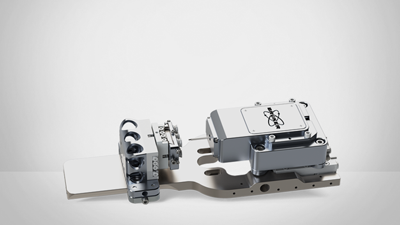

Bruker's transducer technology can be used for direct-pull-tensile samples using a gripper-shaped probe. This technique is available with both low load and high load transducers. Direct-pull-tensile experiments are a popular technique as they offer stable and uniaxial sample loading configuration. It is highly complementary to the other tensile testing option, the patented Push-to-Pull (PTP) device, as they each offer unique sample preparation routes.

The direct-pull-tensile test data can provide a full stress-strain curve, Young’s modulus, yield strength, work hardening, and more. The technique does require sophisticated sample preparation and precise sample positioning. The spindle rotation of the sample in rotation and tilt stage can provide additional advantage in positioning of the sample with respect to the gripper tip and enable EBSD mapping of the sample surface. In 2006, researchers using Bruker’s Hysitron PicoIndenter tools were the first to perform in-situ quantitative testing. This was originally done in the TEM, and was followed swiftly by the SEM.