NMR – Ready for the Big Jobs

NMR Spectroscopy in the Chemical and Petrochemical Industries

Cleaner. More efficient. Sustainable. Some goals are universal, even across fields as varied as the chemical and petrochemical industries. Cleaning up coal and other fuels, creating more efficient catalysts, reducing carbon footprint – these and other projects important to the health of economies, not to mention the health of the planet, are driving innovation around the world.

But while the big ideas get the glory, the real success is in the details.

From Discovery to Validation

Turning a brilliant idea into a process or product, especially in an industrial setting, needs a firm grasp of the details, from feedstock through intermediaries through final product. Even just optimizing an existing process or product to better meet the “cleaner, more efficient, more sustainable” goals calls for exacting quality controls to ensure a consistent product.

Nuclear magnetic resonance spectroscopy can help every step of the way.

In the area of industrial chemistry research, solid-state 1H NMR spectroscopy has been used to characterize tungsten oxide (WO) catalysts deposited on mesoporous silica using atomic layer deposition, and compare them to WO catalysts deposited on the same substrate using the more common method of impregnation. Liquid-state 1H NMR spectroscopy has been used to characterize solid base catalysts for transesterification of triglycerides, a step in the production of biodiesel.

In the petrochemical industry, NMR spectroscopy has long been popular for reaction monitoring and quality control, but as techniques and technology improve, its use has grown across the industry. NMR well logging provides a wealth of information, such as substrate porosity, and the identities and characteristics of the fluid present, their compositions, and their viscosities, and all under very challenging conditions. Benchtop systems are becoming more common and affordable, and are providing more convenient fuel sample analyses in refinery labs.

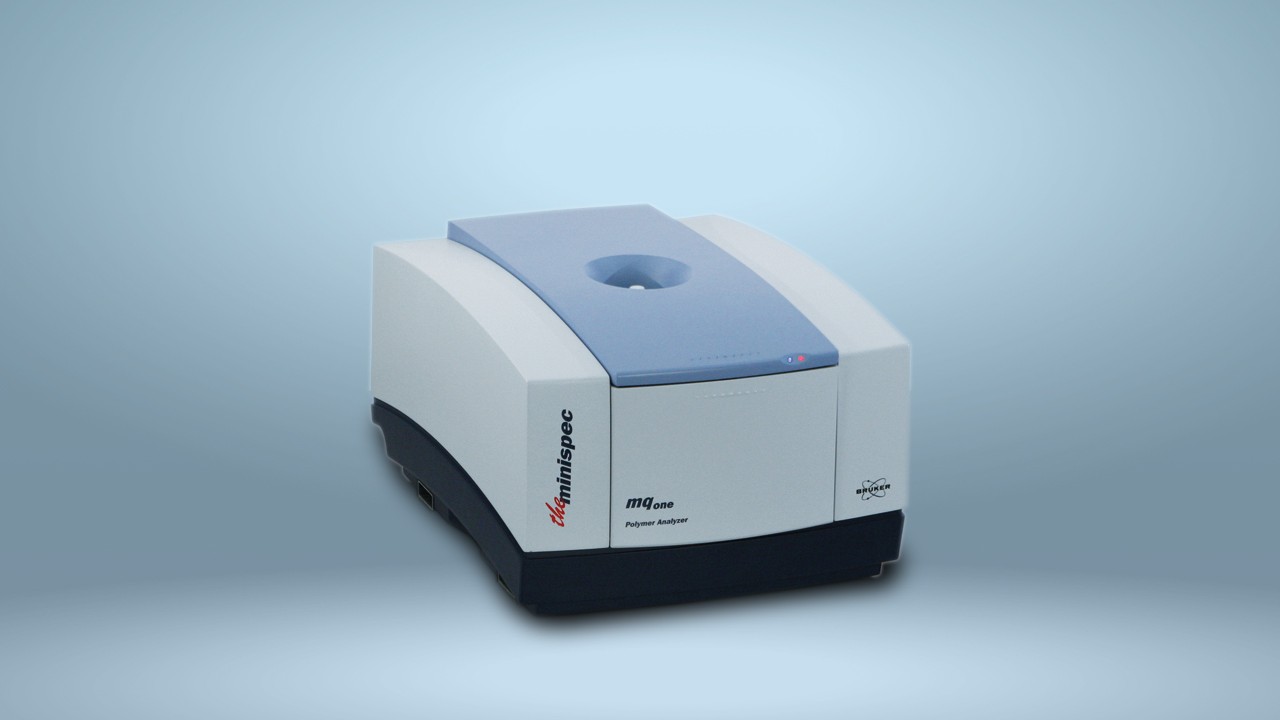

Time-domain (TD) NMR spectroscopy is ideally suited for quality control, and has been used for precisely that purpose in several industries, including fuel production, polymers, and production of fine and specialty chemicals.

Electron paramagnetic resonance (EPR) spectroscopy has also found uses in industrial chemistry. For example, researchers used EPR spectroscopy to study the interactions of sulfur dioxide with manganese oxide and calcium oxide, an example of sulfur contamination of alkaline-earth oxide surfaces, which has important consequences in many chemistry fields such as surface science and catalysis.

The Right Information at the Right TIme

With the variety of techniques and the range of instrumentation offered by NMR spectroscopy, it can be put to use in a multitude of settings: universities, industrial research labs, and even in the field. With so many options, NMR has earned a place in all facets of research and development, from evaluating a prototype to quality-checking the final product. The wealth of information it provides about chemicals under analysis makes NMR spectroscopy an excellent tool for reaction monitoring. With consistent, reproducible results from instrument to instrument and from lab to lab, NMR spectroscopy is just as fine a tool for material validation.