Process Research and Benchtop Online NMR

to execute complex workflows, reduce development time, and achieve consistent, reproducible

results in your research. From high-throughput research to real-time data acquisition,

FLEX AUTOPLANT enables innovation at every stage, supporting a wide range of applications.

Advancing Process Research with Precision and Automation

FLEX AUTOPLANT redefines process research and chemical development by combining state-of-the-art benchtop NMR with fully automated solutions. Designed to enhance efficiency, optimize reactions, and address complex challenges, it provides the precision and adaptability needed to drive innovation in industrial applications.

Automated Process Research Chemical Development with Online NMR Analysis

Workflow

Optimize your workflows with FLEX AUTOPLANT’s fully automated solutions. From gravimetric dispensing to crystallization, every step is streamlined to ensure precise, consistent results in pharmaceutical, polymer, and specialty chemical applications.

Benefits

- Accelerate R&D workflows with automated, parallel synthesis.

- Achieve up to 100x productivity improvement over manual methods.

- Reduce complexity with versatile, modular reactor configurations.

- Enhance reaction optimization with online/offline NMR analytics.

- Improve reproducibility and consistency across experiments.

- Save time with drag-and-drop control via intuitive AUTOSUITE software.

Applications

- Enabling breakthrough reaction pathway analysis and intermediate characterization in organic and inorganic chemistry.

- High-throughput screening for catalyst development and chemical synthesis.

- Materials science research, including polymer development and advanced composites.

- Specialty chemical development with precise reaction optimization and scale-up.

- Workflows for crystallization, distillation, and reaction monitoring in chemical and industrial research.

Comprehensive Features and Advantages of FLEX AUTOPLANT

| Key Advantage / Feature | Description |

|---|---|

| Fully automated system | Integrated reaction preparation, synthesis, work-up, analysis, and output to storage vials for both solid- and liquid-phase library synthesis and reaction screening. |

| High-precision glass reactor arrays | Easy-to-use, disposable, multifunctional arrays with reaction scales from µL to mL. |

| Screwless, self-sealing reactor design | Supports mixing by shaking (up to 1,000 rpm), heating (up to 150°C), cooling (-20°C), refluxing, vacuum, inertization, evaporation, L/L extraction, filtration, solid-phase extraction, crystallization, and drying. |

| Proprietary robotic tool exchange | Ensures flexibility in automation. |

| Gravimetric solid handling | Handles solids from μg to g. |

| Gravimetric liquid handling | Handles liquids from mg to g and μL to mL. |

| Proven liquid handling | Includes pH adjustment, filtration, and heated needle extension. |

| Hight throughput | Supports 24 / 48 / 96 / more parallel reactions per run. |

| Integrated analytics | Includes benchtop online NMR, HPLC (MS), UPLC (MS), GC (MS), UV-VIS, NIR / MIR / DLS measurement cell. |

| Safety and conditioning | Ventilated hood ensures safe and conditioned operation. |

| AUTOSUITE Software | Drag-and-drop experimentation with integration to LIMS, ELN, data analysis, and AI/ML closed loop. |

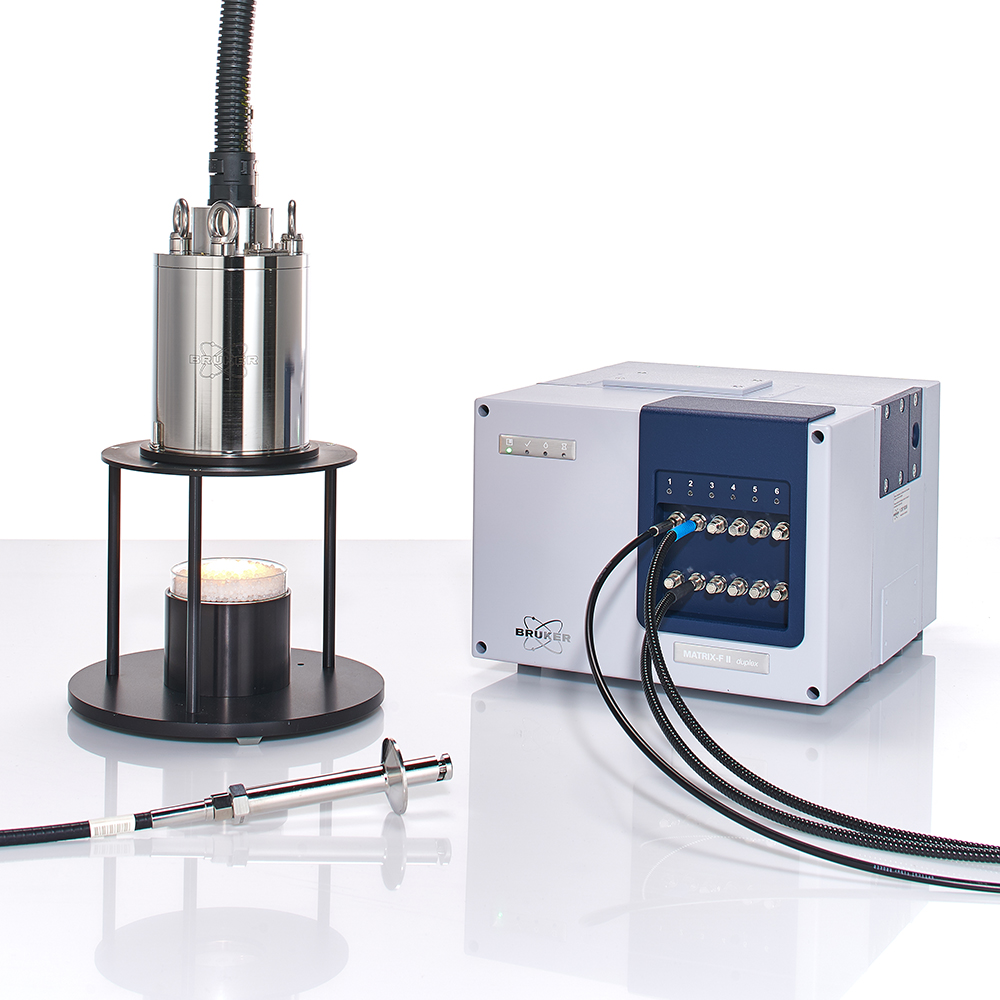

| Benchtop NMR integration | Includes NMR devices (e.g., Bruker Fourier Rxn Lite) with 80 MHz operating frequencies. |

| NMR capabilities | Supports 1D and 2D spectra, sample injection, flow cell and standard 5 mm sample tube options, permanent magnet (no liquid nitrogen/helium), and a 2 Gauss line within the device housing. |

Stay Ahead with Our Expert-Led Webinars

Whether you're optimizing industrial processes, exploring polymer analysis, or advancing quality control, our on-demand sessions provide practical insights, expert knowledge, and innovative approaches to tackle today’s scientific challenges.

Testimonials

Accelerating Discovery: Automation Meets Benchtop NMR

Interview with Dr. Jean-François Ayme, University of Liverpool

Discover how automation and benchtop NMR are transforming synthetic chemistry workflows in this exclusive interview with Dr. Jean-François Ayme, Research Coordinator at the University of Liverpool. Learn how the integration of Chemspeed’s automation platform with the Fourier 80 enables high-throughput experimentation, standardized data collection, and AI-driven insights paving the way for faster, smarter chemical innovation.

Automated Lab: Automating Chemistry with Intelligence

Interview with Dr. Sriram Vijayakrishnan, University of Liverpool

In this insightful interview, Dr. Sriram Vijayakrishnan shares how mobile robots, benchtop NMR, and AI-driven automation are reshaping synthetic chemistry.

Discover how closed-loop organic synthesis and integrated analytical techniques are enabling smarter, safer, and more sustainable workflows.

Bringing lab automation closer to human decision-making than ever before.

Smarter Chemistry: AI and Automation in Drug Discovery

Interview with Lyubomir Kotopanov, University of Liverpool

In this interview, PhD student Lyubomir Kotopanov shares how automation and benchtop NMR are accelerating drug discovery at the University of Liverpool.

Learn how standardized data generation, AI integration, and real-time reaction monitoring are transforming organic synthesis workflows and uncover how unexpected results can lead to new scientific breakthroughs.