M4 TORNADO

Configurable to Your Needs

Ultimate Speed and Accuracy

High Performance micro-XRF with Market-Leading Speed and Flexibility

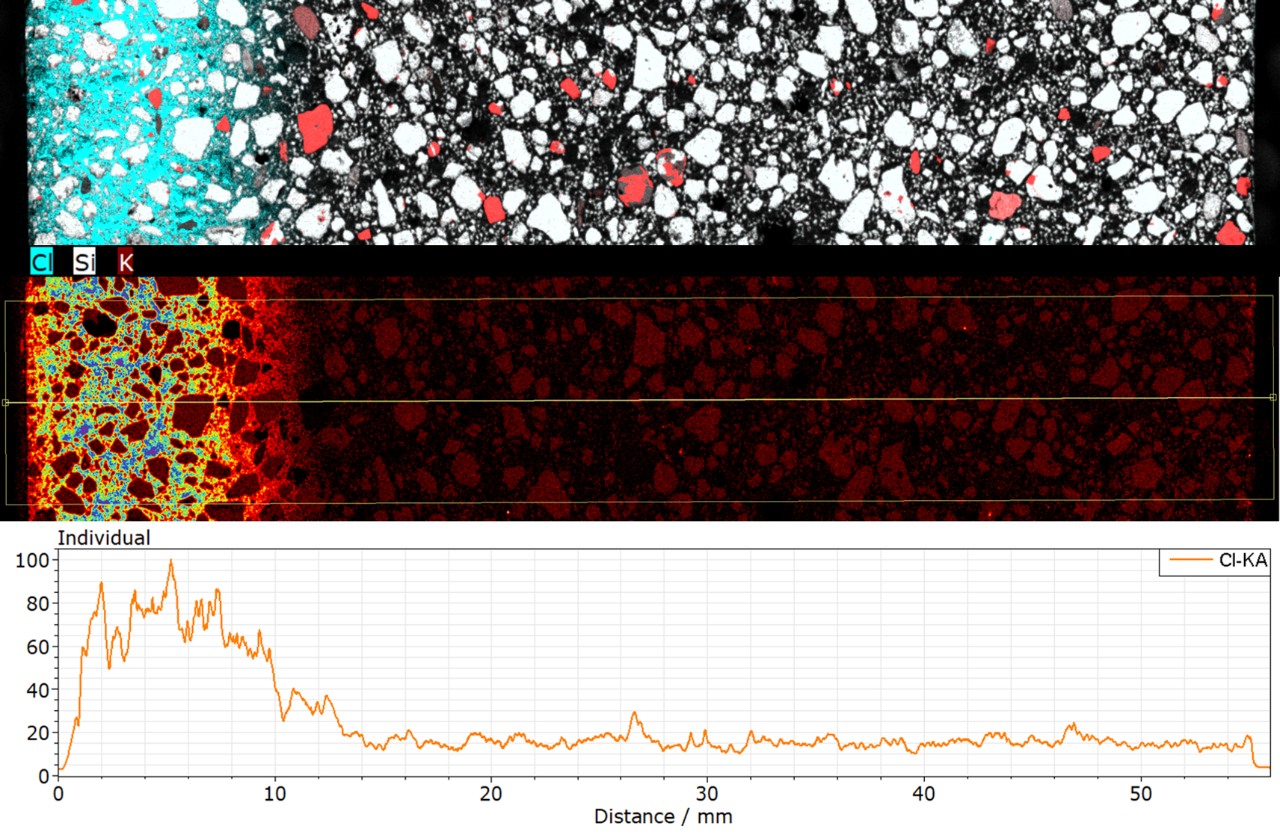

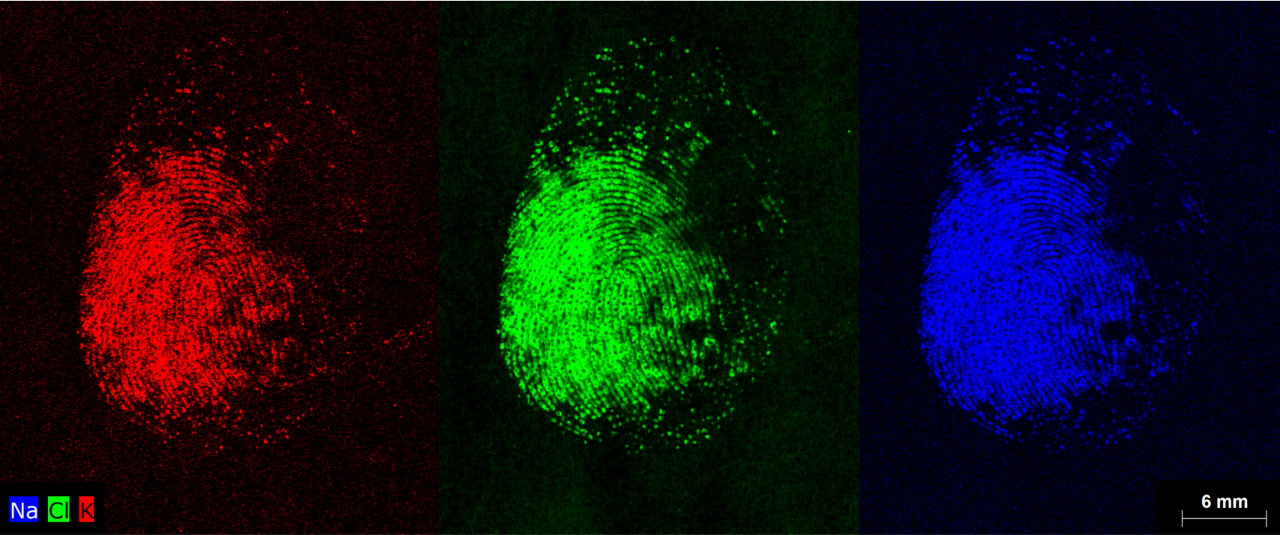

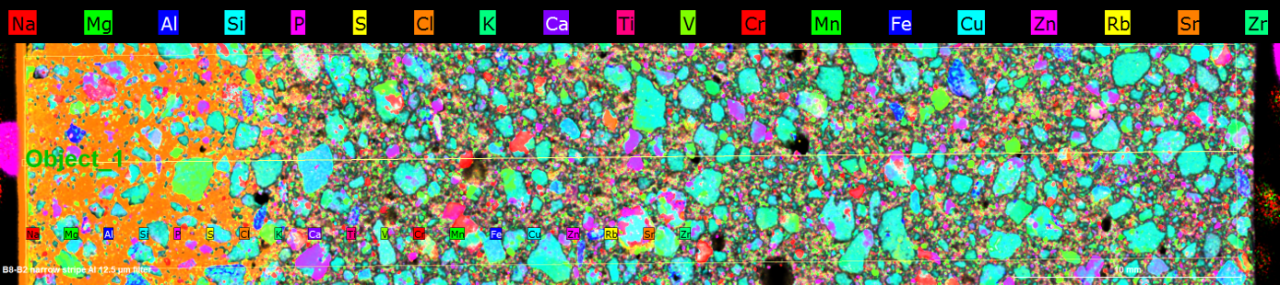

The M4 TORNADO is the tool of choice for sample characterization using small-spot micro X-ray fluorescence. Its measurements give information about composition and element distribution, even from below the surface. Bruker's micro-XRF spectrometer is optimized for high-speed analyses of points, lines and 2D area scans (element mapping) of any kind of sample; be it organic, inorganic or liquid.

The primary X-ray excitation uses a polycapillary lens offering small spot sizes and high X-ray intensity. The M4 TORNADO is configurable with a variety of Bruker XFlash® silicon drift detectors (SDD), offering high throughput without compromising energy resolution.

One of the outstanding configuration options of the M4 TORNADO is the additional X-ray tube, which offers a different target material and a collimator changer for extended analytical capabilities.

Further state-of-the-art configuration options:

- He-flush to increase light element performance while maintaining atmospheric pressure in the chamber

- A quick-exchange stage and a geo-sample holder packaged for thin sections and drill cores

- XMethod software for standard-supported and fully standard-based quantification as well as layer thickness calculation

- AMICS software for automated mineral analysis

How Can the M4 TORNADO Support Your Analyses?

Decrease measurement times. Optimized X-ray excitation path, high-throughput detectors, "on-the-fly" mapping with pixel times down to 1 ms.

Measure samples up to 7kg. Large vacuum chamber, freely adjustable, constant vacuum down to 2 mbar, automatic helium or nitrogen flush to protect your samples.

Map an area of up to 190 x 160 mm². Recording of up to 40 Mio. pixels in one run, data storage as HyperMap with full spectral information, optical image for every pixel.

Quantify spectra, linescans and mappings. Configurable fundamental parameter method, optional XMethod software package for layer or standard-based quantification, layer analysis of mappings.

Process your data. Powerful software package, extraction of arbitrary object sum spectra (ellipses, rectangles, polygons), extraction of line scans, determination of elements present only at single measurement locations (MaximumPixelSpectrum), chemical phase analysis (Autophase).

Extend your capabilities. Profit from a broad range of configurations to match your analytical needs.

Further Enhance your Analytical Capabilities

The M4 TORNADO can be further enhanced with optional features to address your analytical challenges. From the analysis of light elements to the high-resolution imaging of samples with complex topographies.

LE Option: Light Element Detection with the M4 TORNADO

Light element analysis is possible using the M4 TORNADO Light Element (LE) option.

The LE option significantly improves sensitivity in the low-energy range of 0.5–4 keV facilitating the micro-XRF analysis of elements as light as oxygen. This is achieved through advanced detector technology with ultra-thin windows, a fully controlled vacuum system that enhances low-energy X-ray transmission, and a magnetic electron trap that reduces noise and protects the detector.

Together, these features deliver clear, reliable results for elements such as sodium, magnesium, aluminum, and fluorine.

If even greater levels of light element detection are required we recomend using the M4 TORNADO PLUS.

AMS Option: Sharper Results with Smart Aperature Management System

The Aperture Management System (AMS) option for the M4 TORNADO enhances micro-XRF performance by reducing beam divergence and maintaining a nearly constant spot size, even on samples with uneven surfaces. By reshaping the polycapillary output into a more focused beam profile, AMS preserves high intensity while delivering improved spatial resolution without the need for additional optics.

AMS is available in two options (500 or 1000) which, when needed, can be seamlessly inserted into the beam path via software control.

The AMS Option is particularly valuable for the analysis of samples with fine structural details and surfaces of high topography, such as geological samples, cultural heritage objects and advanced materials.

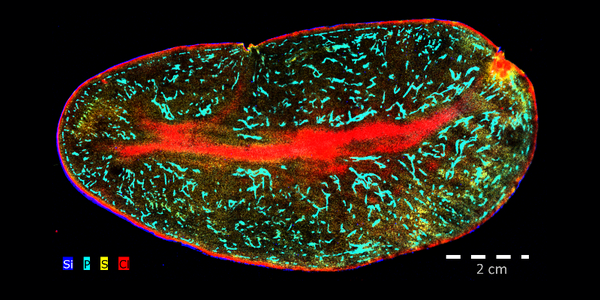

Solving the Puzzle of Mineral Nutrient Homeostasis in Plants

Bruker’s M4 TORNADO Micro XRF spectrometer plays an important role in researching the role of alternative splicing (AS) mechanisms which appear to function in plant responses to environmental stress. Research scientists use the M4 TORNADO to help understand adaptive strategies used by plants to withstand a deficiency or excess of a specific mineral nutrient. This in turn helps determine ways to breed crops with higher mineral nutrient-use efficiency.

Resources & Publications

Brochures & Flyers

Application Notes

- XRF 470 - Analysis of natural and processed food samples

- XRF 469 - Mineral composition analysis using the M4 TORNADO AMICS

- XRF 467 - Combining Micro-XRF and Micro-CT: Mineral measurements of drill cores

- XRF 465 - Standardless and standard-supported fundamental parameter quantification of steel samples

- XRF 464 - Qualitative and quantitative analysis of a large welding joint

- XRF 463 - Fast crystal domain screening using energy dispersive Laue mapping

- XRF 462 - Spatially resolved layer thickness analysis of thin metal coatings

- XRF 461 - Improving the quantification of non-homogeneous samples

- XRF 457 - Analyzing thin layers under vacuum

- XRF 456 - Analysis of geological thin sections

- XRF 455 - Analysis of a large granite sample from the Vredefort Dome

- XRF 452 - Analysis of small particles with micro-XRF

- XRF 451 - Analysis of steel corrosion using micro-XRF

- XRF 447 - distribution analysis of electronic components

- XRF 446 - Elemental composition of Daphnia

- XRF 443 - Analysis of a Roman sword

- XRF 442 - Analytical performance of the M4 TORNADO

- XRF 441 - Elemental distribution analysis on geological samples

Publications

- 2022 - Nature: The Mesozoic terminated in boreal spring

- 2022 - Paleoceanography and Paleoclimatology: Sub-Annual to Interannual Arabian Sea Upwelling, Sea Surface Temperature, and Indian Monsoon Rainfall Reconstructed Using Congruent Micrometer-Scale Climate Proxies

- 2021 - Analytical Chemistry: When Red Turns Black: Influence of the 79 AD Volcanic Eruption and Burial Environment on the Blackening/Darkening of Pompeian Cinnabar

- 2021 - Palaeogeography, Palaeoclimatology, Palaeoecology:The environmental context of carbonaceous compressions and implications for organism preservation 1.40 Ga and 0.63 Ga

- 2021 - Journal of Paleolimnology: (Open Access) Human actions were responsible for both initiation and termination of varve preservation in Lake Vesijärvi, southern Finland

- 2021 - ACS Earth Space Chem.: Geochemical Characterization of the NWA 11273 Lunar Meteorite Using Nondestructive Analytical Techniques: Original, Shocked, and Alteration Mineral Phases

- 2021 - Science Advances - Globally distributed iridium layer preserved within the Chicxulub impact structure

- 2020 - Materials Characterization: Surface analysis of corroded XV–XVI century copper coins by μ-XRF and μ-PIXE/μ-EBS self-consistent analysis

- 2020 - Science of The Total Environment: Decay processes in buildings close to the sea induced by marine aerosol: Salt depositions inside construction materials

- 2020 - Minerals Engineering: Elemental and mineralogical constraints on environmental contamination from slag at Gulf Creek copper mine

- 2020 - Minerals Engineering: Elemental and mineralogical constraints on environmental contamination from slag at Gulf Creek copper mine

- 2020 - Spectrochimica Acta Part B: Atomic Spectroscopy: Energy dispersive X-ray fluorescence quantitative analysis of biological samples with the external standard method

- 2020 - CrystEngComm: Tunable pore size in diopside glass-ceramics with silver nanoparticles

- 2020 - International Journal of Legal Medicine: Arrow entrance wounds with blackened margins simulating bullet wipe

- 2020 - Palaeogeography, Palaeoclimatology, Palaeoecology: Benchtop μXRF as a tool for speleothem trace elemental analysis: Validation, limitations and application on an Eemian to early Weichselian (125–97 ka) stalagmite from Belgium

- 2020 - Journal of Crystal Growth: Growth of CuFeO2 single crystals by the optical floating-zone technique

- 2020 - Radiation Physics and Chemistry: Study of composition and structure of demineralized bone using X-ray techniques