Surface Ventures Mini-Symposium - Electrification impact on brake applications

Ensuring dependable braking performance in EVs

Regenerative braking and reduced pad use shift friction and wear behavior and can increase corrosion risks, so legacy test routines often miss critical effects. Effective test methods must combine mechanical, thermal, and electrical factors to isolate true material and lubricant responses. This symposium gathers experts in the field of tribology of EVs to present research data, discuss instrumented solutions, and answer questions.

Watch this Surface Ventures webinar to learn how:

- Innovative solutions and testing protocols can address environmental and corrosion challenges

- WLTP-based testing protocols are implemented in lab-scale tribometers to screen brake materials for particulate emissions

- Friction and PM10 emissions differ between GCI and coated rotors, and why new friction material formulations are needed for coated rotors

- Lab-scale testing bridges the gap between material development and dynamometer testing for advanced understanding of brake materials

Abstracts

Towards Environmentally-Friendly Friction Brakes, Prof David Barton (University of Leeds)

From this talk, you will learn:

- Environmental issues facing friction brakes.

- Possible solutions to environmental issues

- Testing protocols and latest results

- Effects of corrosion

WLTP Brake Cycle in Tribometers, Dr. Alaitz Zabala and Dr. Iñigo Llavori (Mondragon Unibertsitatea)

From this talk, you will learn:

- Implementation of WLTP-based testing protocols in a lab-scale tribometer

- Identification of key factors for implementing WLTP cycles in a tribometer environment

- Use of tribometer testing for PM emission screening of brake materials

Study of the tribology of friction materials for brake pads related to the PM10 emissions: coupling with gray cast iron discs vs hard coatings, Dr Agusti Sin Xicola (ITT Motion Technologies)

From this talk, you will learn:

- Differences in friction and evolution of PM10 between a GCI rotor compared to different types of coated rotors.

- About the tribolayer generated between the friction material and the coated rotors compared to gray cast iron.

- The importance of generating new friction material formulations for the coated rotors to meet all the emissions and performance demands.

Dr. Argusti Sin Xicola's presentation is not available for the recording

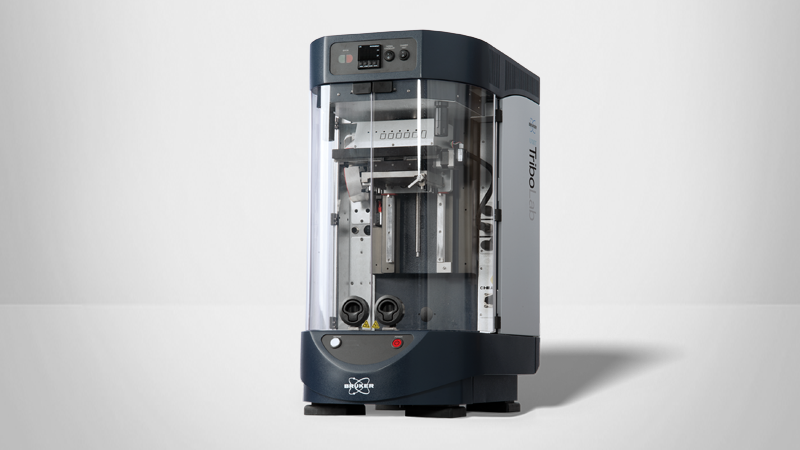

Bruker Tribology solution for brake applications: How to better understand the tribology behaviour of brake contacts, Dr Mohamadou Diew (Bruker)

From this talk, you will learn:

- Brake applications basis and screening test methods

- New challenges with e-vehicles and Euro 7 standards

- How to bridge the Gap between material development and Dynamometer with lab scale coupon for more understanding of the tribological behavior of brake materials with Multiscale approach

Featured Products and Technology

Speakers

Dr. Alaitz Zabala, Mondragon Unibertsitatea

Dr. Alaitz Zabala is Associate Professor and head of the Surface Technologies group at the Department of Mechanics and Industrial Production at Mondragon University. Her research focuses on tribology, surface metrology, and surface functionalization, with applications across various industrial sectors.

Dr. Iñigo Llavori, Mondragon Unibertsitatea

Dr. Iñigo Llavori is Associate Professor and researcher at Mondragon University. He holds a PhD in Mechanics and Materials and participated over 30 competitive projects. His work focuses on surface engineering (tribology, fatigue, fracture), combining experiments and simulation and has authored 50+ scientific papers.

Agusti Sin Xicola, Ph.D., Materials & Process Innovation Director, ITT Friction Technologies

Agusti Sin earned his MSc. from the Faculty of Chemistry at the University of Barcelona and completed his Ph.D. at the Institute of Materials Science of the Spanish Scientific National Council in 1998. Since 2014, he has been serving as the Director of Advanced Research at ITT Friction Technologies, where he leads Materials and Process Innovation. Since 2019, he has held the role of Co-founder and Co-Director of Research for the Joint Lab between ITT and the University of Turin.

Dr Mohamadou Diew, Tribology Applications Scientist, Bruker Nano Surfaces and Metrology

Dr. Mohamadou Diew is a Tribology Applications Scientist at Bruker Nano Surfaces & Metrology. With over 19 years of experience, he specializes in tribology, contact mechanics, materials, coatings, and wear. He completed his PhD at École Centrale de Lyon, focusing on friction modifiers and lubrication regimes. Dr. Diew works on various tribology applications for industries and for academics.