nanoDynamic Mode

Apply an oscillating force to continuously measure viscoelastic and fatigue properties as a function of contact depth, frequency, and time

Materials such as biological materials, glasses, polymers, and some metals exhibit significant time dependency with respect to mechanical properties. This viscoelasticity makes it difficult to completely describe the material response using traditional nanoindentation techniques. Building upon traditional dynamic mechanical analysis theory (DMA), Bruker has established its nanoDynamic Mode option for the in-situ mechanical analysis of nanoscale materials.

nanoDynamic Mode offers several testing modes in which an oscillating force is applied to a sample and the resultant displacement amplitude and phase shift are measured using a lock-in amplifier. Using this technique, the contact stiffness and damping properties of the material can be accurately determined, allowing for the measurement of storage (E’) and loss (E’’) moduli, as well as tan delta. Additionally, this technique has been expanded to include additional testing modes for characterizing creep and inducing fatigue in a wide variety of materials or structures while deformation is simultaneously monitored with the electron microscope.

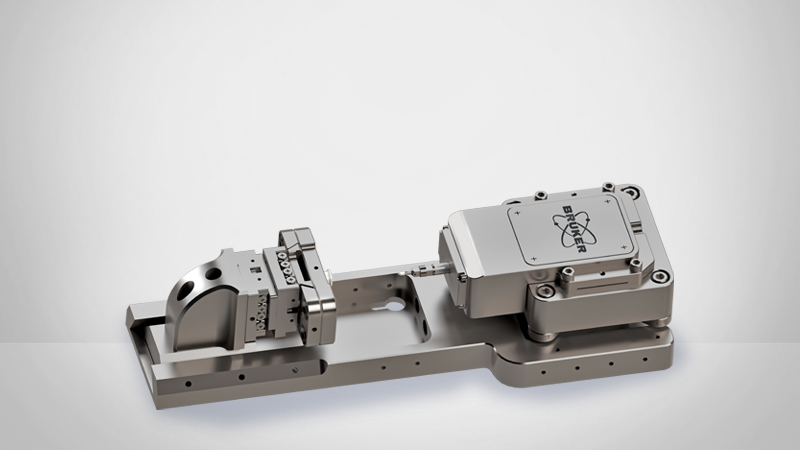

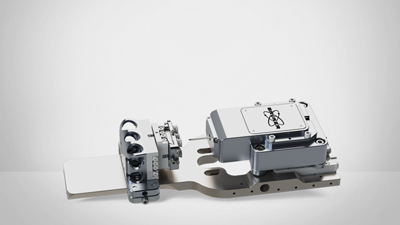

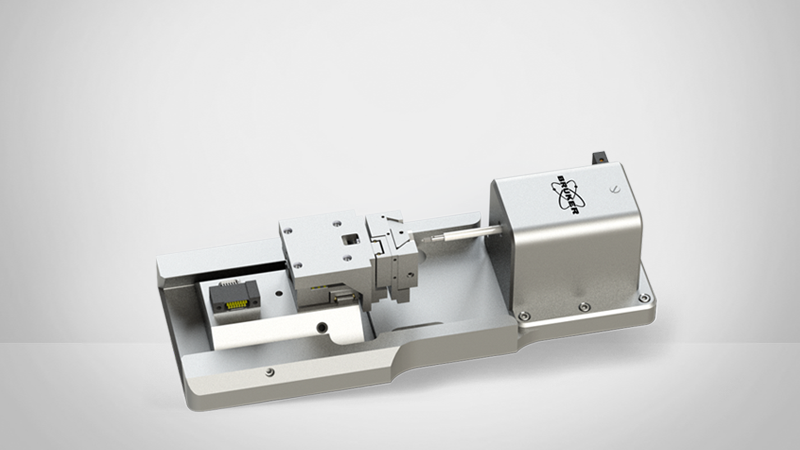

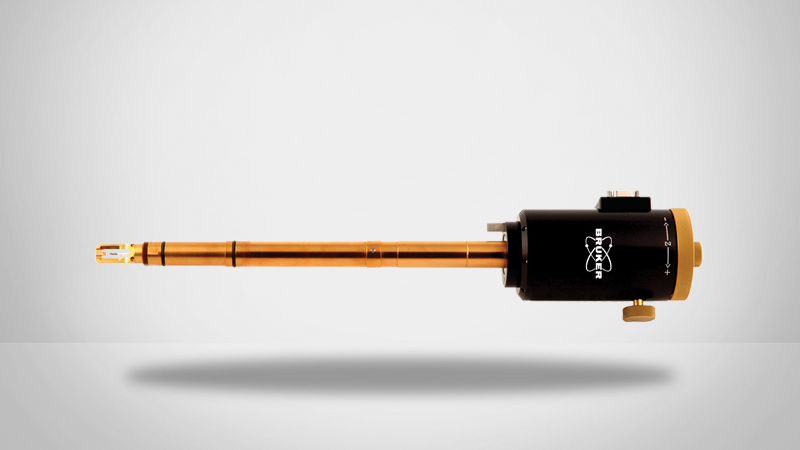

High Load DMA for Hysitron PI 89

Bruker's Hysitron PI 89 SEM PicoIndenter is also available with a higher load DMA capability that enables nanometer-to-micron dynamic property measurements. 10mN, 500mN and 3.5N transducers with advanced control electronics fully optimize small and large-scale dynamic testing and provide industry-leading performance and sensitivity. While standard nanoDynamic Mode (low load) is useful for understanding dynamic properties of smaller structures and indentation at lower depth, High Load DMA is better for analyzing high-strength materials, studying large pillar and particle compression, profiling higher indentation depths, identifying compression of large 3D lattice structures and soft materials, and characterizing higher strain in cantilever samples.