Noncontact Optical-Based Metrology for Microlens Characterization

High-throughput metrology control of microlenses is critical for lens development, process optimization, and mass production

In this webinar, Bruker Senior Marketing Application Specialist Roger Posusta discusses microlenses, why white-light interferometry (WLI) is the best technique for their characterization, and the available products in Bruker’s WLI lineup.

Use WLI-Based Optical Measurement for Microlens Characterization

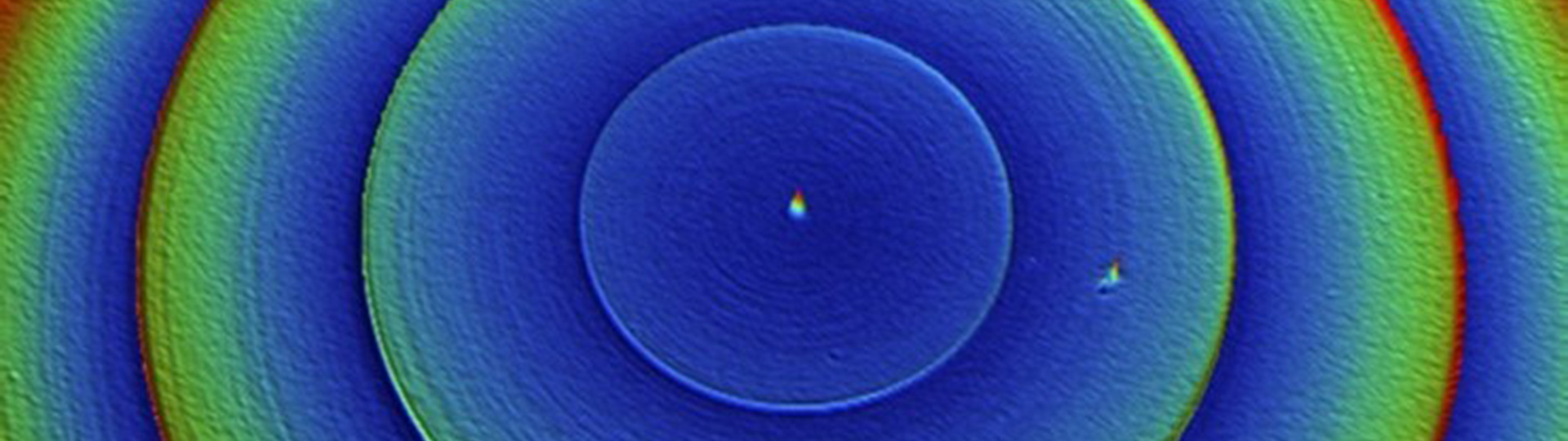

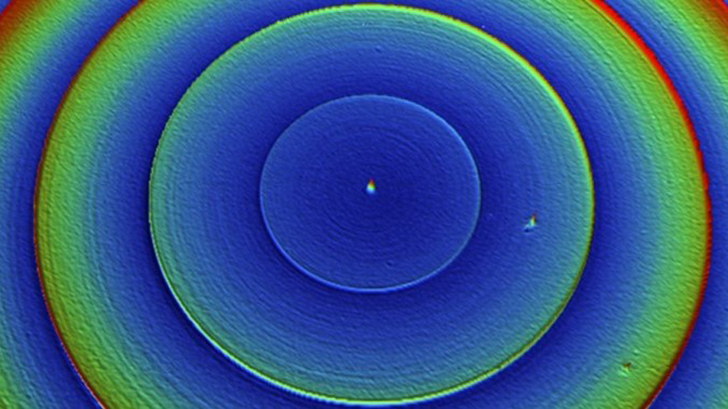

Microlenses are critical components used in a wide variety of consumer devices and industrial sensors, ranging from cellphone cameras and virtual reality goggles to 3D displays and advanced driver-assistance systems. Simple lenses have a fixed radius of curvature, but more complex aspheric shapes provide sharper focusing, less distortion, and astigmatism correction. Other design advancements include arrays of microlenses that can focus light from large fields of view to individual pixels on a CMOS camera, and a Fresnel microlens that can minimize chromatic aberration. Usually ranging in sizes from a millimeter to a few microns in diameter, microlenses, including complex ones, are produced in large volumes. Since microroughness and geometry factors directly affect performance, high-throughput metrology control of microlenses is critical for lens development, process optimization, and mass production within tolerances.

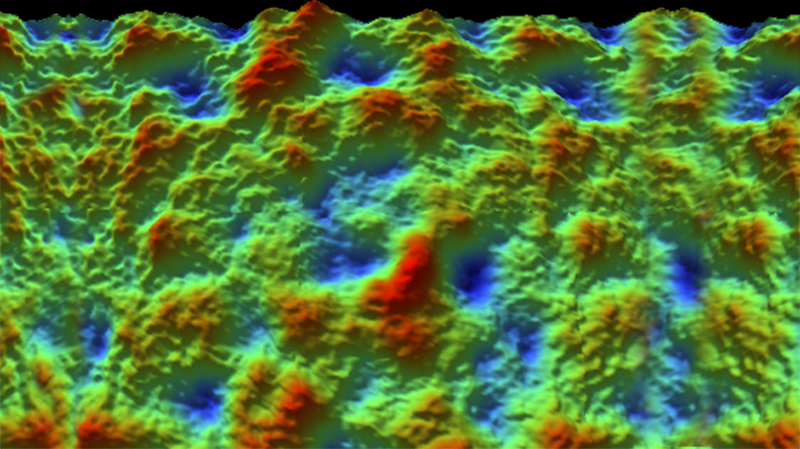

Roger Posusta of Bruker Nano Inc. discusses how white light interferometry (WLI) has the capability to encompass several lenses in a large field of view while maintaining subnanometer height resolution and micron-level lateral resolution. WLI is an ideal optical measurement technique for characterizing these types of surfaces. Bruker’s industry-leading WLI solutions combine automation and on-the-fly analysis to enable comprehensive reports on lens parameters. Posusta also covers curvature analysis through the Zernike coefficient, defect monitoring via slope-based detection, and deviation from ideal aspheric shape. Finally, he illustrates the calculation of the conic parameter using automatic lens shape detection, which enables the high-throughput and advanced characterization of the most complex microlenses.

Summary

Characterization and metrology for microlenses is typically conducted using one of three techniques: (1) stylus scanning, (2) large-aperture interferometry, or (3) WLI full-areal optical scanning. The first, stylus scanning, is slow to characterize a full lens shape since it only can generate data for one point at a time. The second, large-aperture interferometry, lacks lateral resolution due to the optical setup. The third, WLI full-areal optical scanning, avoids the limitations of (1) and (2). With WLI, fast, non-contact scans can be conducted at high vertical and lateral resolution.

What is a WLI and how does it work? Essentially, a WLI is just an optical microscope, but with special interferometric objective lenses. Thanks to these lenses, the system can collect information about the constructive and destructive interference of light reflected from different locations, which is then analyzed to provide information about sample topography. The entire field of view is imaged simultaneously and at a distance, making it an areal, non-contact technique.

The primary benefits of WLI for microlenses are that it is fast and non-contact. Also important for microlenses, sample compatibility is broad. Parts can be measured even if they are shiny and curved, transparent, or black in color. With Bruker WLI systems, users can additionally take advantage of circular stitching, speed-increasing scan length reduction features, and automated microlens-relevant analysis capabilities.

Find out more about the technology featured in this webinar or our other solutions for microlens measurement:

Featured Products and Technology

Speaker(s)

Roger Posusta, Senior Marketing Application Specialist, Bruker Nano Inc.

Roger Posusta is a senior marketing application specialist at Bruker Nano Inc. He has over 35 years of experience helping industry and academia implement noncontact metrology solutions to solve their most challenging applications.