MOVE-T液态乳品分析仪

滴滴精准

探索MOVE-T分析仪

生乳及乳品的分析对确保质量、安全和符合行业标准至关重要。傅立叶变换近红外(FT-NIR)技术以其快速、无损的检测能力著称,可精准、可重复地分析乳品中的脂肪、蛋白质、乳糖及总固体含量。

全新MOVE-T是一款紧凑型FT-NIR台式分析仪,专注于液态样品检测,涵盖生乳、液态成品、中间产物及酸奶配料。

- 先进的FT-NIR技术:提供精准可靠的分析

- 耐磨石英流通池:具备免维护耐久性

- 二合一进样系统:实现高效样品处理

- 自动清洗功能:每次检测都获得稳定可靠的结果

Need more info?

创新的二合一进样系统

MOVE-T的二合一进样系统专为优化工作流程而设计,通过自动化产品处理提升检测效率与精度。该双流路模式系统可通过软件控制,根据产品特性在强力均质泵与蠕动泵之间智能切换,实现样品处理与输送。与传统FT-IR乳品分析仪不同,MOVE-T能轻松处理包括高粘度液态乳品在内的各类样品。

MOVE-T具有无与伦比的灵活性,确保样品制备一致性并减少人工干预。无论您需要均质处理还是直接泵送,MOVE-T都能精准适配需求,确保每次检测都获得最优结果。

为何分析前需要对生乳进行均质化处理?

生乳均质化可将脂肪球分解为更小且分布均匀的微粒,防止顶部形成奶油层。这种处理方式可确保生乳样品均一性,这对获得准确且可重复的分析结果至关重要。

此外,均质化生乳稳定性更高,能减少分析过程中的分层现象,从而帮助获取可靠的测量数据。

何时使用蠕动泵?

与生乳不同,其他类型乳品及液态乳品在分析时无需均质化处理。配备1,000µm光程的测量池可兼容奶油、冰淇淋,酸奶配料等粘稠样品,以及含添加剂或结晶糖的液态产品。

仅使用蠕动泵(跳过均质步骤)还能延长维护周期及均质器使用寿命。

应用

通过配备我们的多样化定标模型库,可扩展MOVE-T分析仪的功能。该模型库专为精准分析各类产品而设计,涵盖从生乳到多种乳制品及成品的检测需求。其中包含针对固形物、脂肪、蛋白质和乳糖等关键参数的稳定定标方法,并根据产品特性提供其他组分的附加参数检测。

我们的定标校准方法具备高度适应性,可进行本地化优化以满足您的特定需求。所有方法开发与验证流程均严格遵循ISO 21543 IDF 201:2020标准,以确保最高可靠性。

此外,我们的专家团队将持续更新这些方法以融合最新技术进展,为您提供实现精准高效分析的尖端工具。这确保您的MOVE-T分析仪始终处于行业标准前沿,每次检测都能提供稳定可靠的结果。

常见问题

Key features of the MOVE-T to ensure robustness and seamless integration into your quality control process include:

- Precise Temperature Control: The flow cell temperature is monitored and regulated via an infrared sensor embedded inside the heating block, ensuring consistent measurement conditions.

- Autogain Functionality: As with the TANGO series, the MOVE-T supports “Autogain”, enabling automatic optimization for varying product matrices without manual adjustment.

- Long-life Light Source: The sealed optical system is equipped with a high-intensity light source offering a mean time to failure (MTTF) of 3 years, ensuring long-term operational stability.

- Automated Background Measurement: An integrated mechanism allows for background measurements with a fixed-position flow cell, eliminating the need for manual intervention.

These design elements contribute to a robust, user-friendly system that delivers reliable and reproducible results over extended periods of operation.

The MOVE-T for liquid dairy products and can analyze a wide range of samples, including:

- Raw milk & processed milk

- Fermented milk products

- Cream-based products

- Condensed & evaporated milk

- Whey and protein products

- Milk drinks and premixes

- Liquid ice cream

- Plant-based dairy alternatives

This flexibility makes it suitable for various stages of dairy production, from raw milk to finished products.

We know that reliable analyzers are essential to the dairy industry. This is why all our method development and validation procedures with the MOVE-T and other dairy analyzers based on FT-NIR spectroscopy are according to the ISO 21543 IDF 201:2020 guidelines, giving you peace of mind.

Moreover, Bruker Optics itself is ISO certified. The company holds certifications for ISO 9001, ISO 13485, ISO 14001, and ISO 50001, ensuring that their products meet high standards of quality, environmental management, and energy management.

In addition to the MOVE-T, Bruker offers various other analyzers for the dairy market based on FT-NIR technology:

- The MPA III Dairy Analyzer sets a new standard for analyzing both liquid and solid samples, featuring a software-controlled Liquid Sampling Module, homogenizer, and peristaltic pump to ensure precise and repeatable results across a wide range of dairy products.

- The TANGO analyzer, known for its simplicity and reliability, uses FT-NIR spectroscopy to provide accurate analysis of cheese and other dairy products, making it ideal for routine quality checks with its user-friendly interface and robust design.

- The BEAM, an automated system, streamlines the analysis process by reducing manual intervention and increasing throughput, effectively monitoring and controlling production processes to ensure consistent product quality.

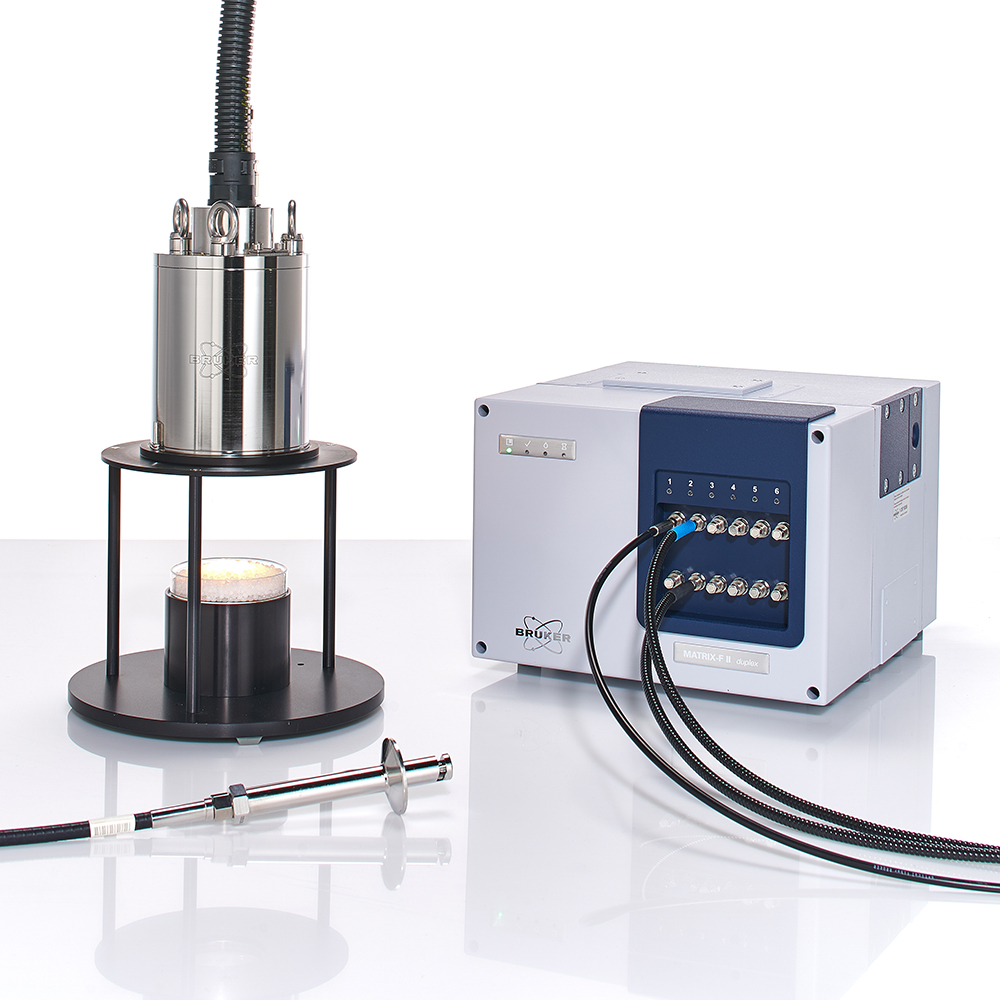

- The MATRIX-F II, a high-performance FT-NIR analyzer, is designed for in-line process control, offering real-time monitoring to optimize production efficiency and maintain high standards of product quality.

Collectively, these analyzers empower the dairy industry to maintain quality, improve efficiency, and ensure product consistency.