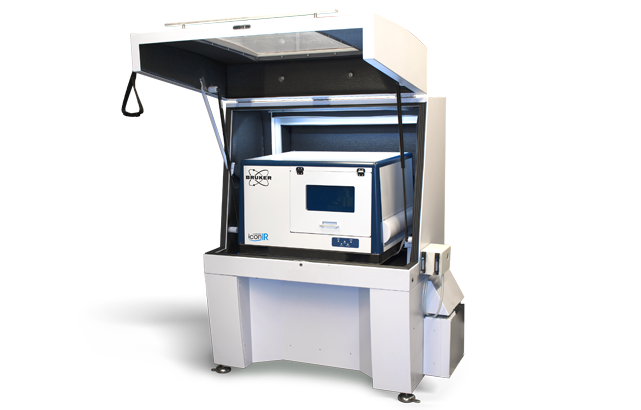

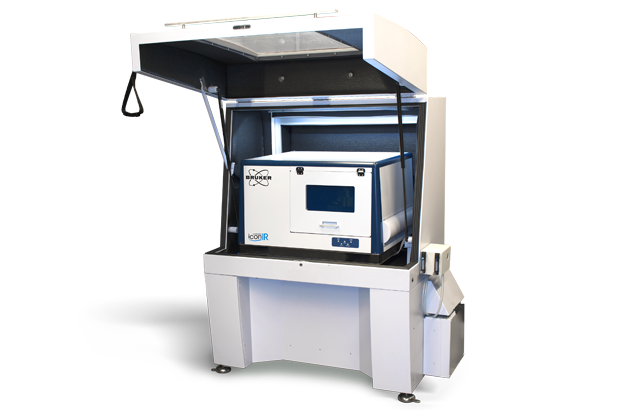

Dimension IconIR

Dimension IconIR

布鲁克大样品台Dimension IconIR系统将纳米红外光谱技术(AFM-IR)和扫描探针技术(SPM)集成到一个平台,为学术界和工业界用户提供先进的纳米光谱、化学成像和物理性质成像工具。IconIR结合了数十年的研究和技术创新,基于Dimension Icon ®原子力显微镜的最新平台,实现卓越的纳米级属性成像能力。该系统支持相关的显微镜和化学成像,具有超高空间分辨率和单层灵敏度,同时其独特的大样品台结构,提供极大的样本灵活性,大大扩展应用领域。

凭借先进的红外激光光源,精心的系统设计和用户友好的操作模式,布鲁克Dimension IconIR平台为用户提供优异的纳米光谱检测。详情请参考应用指南“Dimension IconIR-高性能纳米尺度红外光谱和成像系统”。

To learn more, continue reading, contact us, or see FAQs about this product.

卓越的纳米红外功能和性能

在单个系统中,IconIR提供高性能纳米级红外光谱、化学成像分辨率和单分子层灵敏度。

Dimension IconIR提供:

· 与FTIR高度一致的高性能纳米红外光谱,优于10nm化学成像分辨率和单分子层灵敏度

· 化学成像可与PeakForce Tapping®纳米机械和纳米电学关联

· 高性能AFM成像和极大的样品灵活性,可容纳大尺寸样品*

· 广泛适用的应用组件和AFM功能模块

*标准系统支持150mm大样品,也可提供能够容纳更大样品的版本

完整的关联研究显微镜

集成Bruker特有的PeakForce轻敲纳米物性成像和纳米红外光谱技术,Dimension IconIR系统的大样本平台特别适合于电学或化学反应环境中材料和活性纳米系统,甚至是具有强机械异质性的复杂系统的关联研究。

IconIR提供:

先进的定量属性成像技术

用于定量纳米化学,纳米机械和纳米电学表征的完整关联研究方案

高性能纳米红外光谱

布鲁克是基于光热AFM-IR纳米红外光谱技术的发明者,并拥有多项专利和独特的纳米红外模式。这些模式使IconIR能够提供与FT-IR光谱一致的高速、高性能光谱。模式的多样性为工业和学术用户的广泛样本提供测试支持。

IconIR提供:

与FT-IR一致的高性能,丰富,详细的光谱,实现单分子光谱

共振增强AFM-IR,纳米红外领域的首选技术,已发表大量科学出版物

高性能轻敲模式AFM-IR光谱

超高分辨率化学成像

Icon业界领先的AFM性能和Bruker专利的轻敲AFM-IR成像共同提高了纳米红外技术的空间分辨率和样品适用性,并将其应用扩展到光热AFM-IR技术目前尚未解决的领域。

IconIR提供:

· 优于10nm的空间分辨率,用于广泛的材料类型(包括软质材料)的化学成像

· 分子层灵敏度用于薄膜及生物结构成像

· 一致,可靠,高质量的可发表数据

· 聚合物薄膜的可靠表面敏感化学测量

浅表面化学信息检测

采用布鲁克最新专利表面灵敏模式,IconIR将探测深度从500纳米降低到数十纳米,无需制备截面,无缝结合高空间分辨率和高表面灵敏度。

Frequently Asked Questions

Dimension IconIR supports Tapping AFM-IR and Resonance Enhanced AFM-IR as standard modes. Surface Sensitive AFM-IR and REFV AFM-IR are available as options, depending on the system’s configuration and accessories.

IconIR supports samples up to 150 millimeters in diameter and is designed for either multiple coupons or large-sample workflows. Bruker also has the Dimension IconIR 300 for full access on 200 mm and 300 mm wafers. If you need to work with larger or heavier samples, consult Bruker for custom solutions.

Standard Dimension Icon AFMs cannot be routinely upgraded to IconIR systems. IconIR is a dedicated platform with integrated IR capability.

More About Bruker's Nanoscale Infrared Technology

Yes. Bruker’s photothermal AFM-IR technology produces spectra that are directly comparable to FTIR spectra, as demonstrated in published documentation and peer-reviewed articles. AFM-IR spectra can be searched directly against FTIR spectral databases. If FTIR-like spectral analysis is critical for your application, our experts can provide evidence showing spectral correlation.

Photothermal AFM-IR provides direct absorption-based spectra that closely match FTIR results and are easier to interpret than Raman-AFM or s-SNOM. Further, Photothermal AFM-IR signals are amplified by the resonant enhancement of the cantilever providing the best signal-to-noise of those techniques. Bruker offers s-SNOM as a separate option for advanced near-field studies.

Bruker nanoIR systems routinely achieve chemical imaging with spatial resolution below 10 nm and can detect single molecular layers. Actual performance depends on your sample and selected measurement mode.

Yes, photothermal AFM-IR can chemically map and identify particles smaller than one micron, including nanoplastics and environmental contaminants. Direct correlation to FTIR provides ready interpretation in particles as small as 10 nm.

Bruker’s photothermal AFM-IR systems typically require a single socket of standard electrical power,and CDA. Specific requirements may vary by model, so request a site preparation guide from your Bruker representative.

Bruker photothermal AFM-IR systems primarily use quantum cascade lasers (QCLs) that deliver stable, reliable performance and broad coverage across the mid-infrared fingerprint region as well as optical parametric oscillators (OPOs) for the C-H, O-H, N-H stretching region. Multiple QCL chips can be combined to access all key spectral windows required for routine and advanced research, and additional sources are available for specialized applications. Bruker’s application experts can help you select the optimal laser configuration to match your measurement needs and ensure sufficient spectral resolution for both standard and demanding experiments.

Measurement times vary by application, but point spectra can be acquired in seconds, chemical maps in minutes, and automated recipes can be tailored for high-throughput workflows.

Routine maintenance includes probe replacement, laser alignment checks, and calibration with reference samples. Bruker provides detailed maintenance protocols and support plans.