Raman Spectroscopy

Understanding the relationship between localized mechanical properties and material structure

Direct coupling of Raman spectroscopy with nanoindentation provides comprehensive mechanical characterization capabilities of materials at the nanoscale and its direct correlation to the localized chemical composition. The vibrational (phonon) states of molecules detected using Raman spectroscopy give a molecular fingerprint of the physical state of a matter. At the same time, a nanoindentation curve serves as a fingerprint of a material’s mechanical properties. In-situ Raman mapping performed before mechanical testing allows for precise positioning of the mechanical test based on chemical structure. Additionally, Raman maps performed after nanomechanical tests provide comprehensive information about the internal stress distribution within the material, resulting from plastic deformation during the test. Raman maps can be acquired in fully automated routines together with in-situ SPM imaging, modulus maps, or electrical conductance maps.

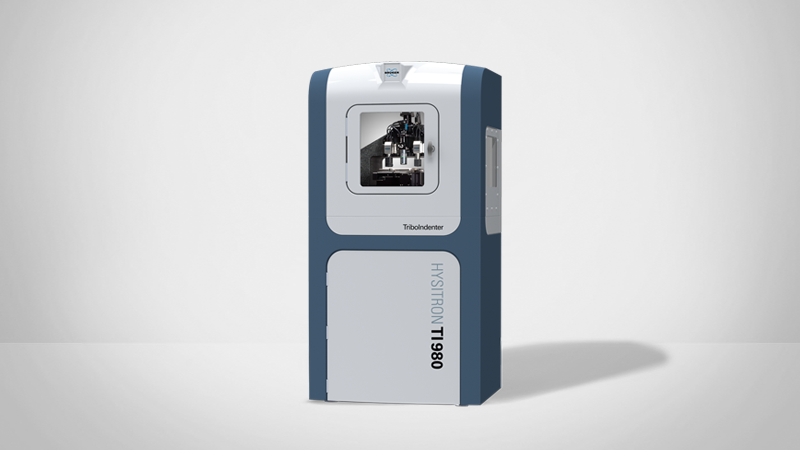

Bruker’s Raman Spectroscopy upgrade option is available on all Hysitron TriboIndenter nanomechanical test instruments, providing a direct relationship between nanomechanical properties and Raman spectra. High precision, encoded stages provide a spatial correlation of 100nm between the two characterization techniques. Bruker preserves the concept of modularity with the Raman-enabled systems; allowing almost any laser source and spectrometer to be used with the system, based on specific research needs.