UMT TriboLab

UMT TriboLab

Bruker’s UMT TriboLab® platform builds on over 25 years of industry-leading Universal Mechanical Tester (UMT) technology to provide the most versatile and accurate testing capabilities on the market.

The system features a unique modular concept that delivers more functionality, higher speeds, more torque, and better force measurement than competing tribometers and testers, while introducing Bruker-exclusive advancements for improved efficiency and ease-of-use.

- Exceptional modularity - Accommodates the full range of speeds and torques to perform nearly every possible tribology test.

- Broadest capabilities - Enable an unprecedented breadth of testing under widest range of environments.

- Unmatched ease of use - Removes the need to learn complex scripting languages or conventions.

To learn more, continue reading, contact us, or see FAQs about this product.

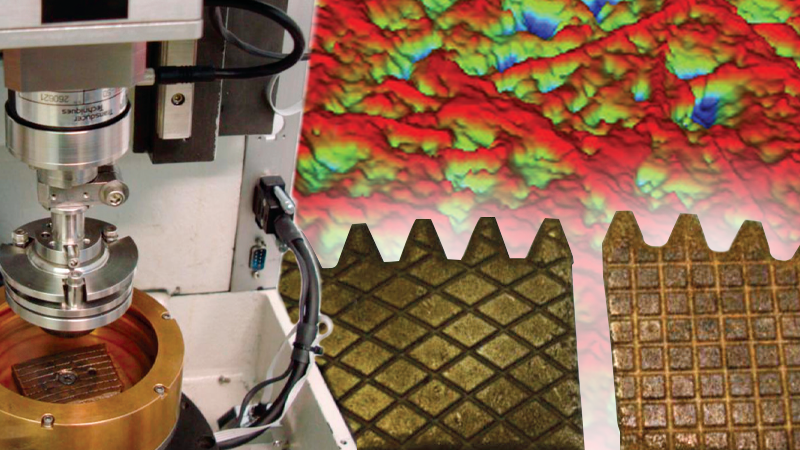

Modular Drives for Maximum Versatility

Quick changeover of drives using tool-less clamping allows the user to position the drive easily, then lock it into place in seconds. No cable connections are required for standard drives, and blind-mate connectors on the mounting ring automatically connect fans, sensors, and other electronics. Each hardware component includes a Tribo ID chip. Software interrogates the system, interprets the chip and “understands” the configuration without operator-entered commands.

Easy and reliable high- and low-temperature testing in industrial applications

Temperature significantly influences wear and friction behavior of materials. The UMT TriboLab™ platform can be equipped with temperature chambers that allow testing up to 1200°C* and down to -40°C. With options available for both the rotary and reciprocating drives, these chambers enable easy, reliable temperature-controlled testing for many demanding research and industrial applications.

*High temperature testing chambers not yet available for sale in Europe.

High-Load, High-Performance Sensors

The UMT TriboLab excels at producing highly accurate and repeatable test data by utilizing the latest developments in sensor technology from Bruker. These new “Gold Series” sensors offer noise levels at an industry-leading 0.02% of full scale values, with circuitry completely redesigned to reduce noise to an absolute minimum. The range of sensors also has been extended to eleven sensors, spanning forces from 1 milliNewton up to 2 kiloNewtons.

Industry-Specific Solutions for Specialized Performance

Bruker has utilized the versatility and modular architecture of the TriboLab platform to create turn-key kits for specific applications and industries. In addition to tailored hardware components, these modules feature software developed in conjunction with industry-leading manufacturers to address targeted standards. Bruker’s industry-specific solutions include:

- Brake Material Screening

- Clutch Friction Material Screening

- HFRR Test

- 3-Point-Bend Testing

- Hot-Hardness Testing

- and more

See More of This System

We are excited to offer a variety of virtual and in-person opportunties for you to get first-hand information about this instrument and discuss your requirements and questions directly with our experts. Find out which 2025 conferences and tradeshows we will be at in your area here:

Frequently Asked Questions

UMT TriboLab supports heating up to 1200 °C (availability may vary by region), cooling down to −40 °C with the optional chiller kit, and humidity control from 5 to 85% relative humidity.

The system supports a force range from 1 mN to 2 kN, torque up to 5 N∙m at 100 rpm (2.5 N∙m at 5000 rpm), rotary motion up to 5000 rpm, and reciprocating motion up to 60 Hz.

Available configurations include pin-on-disk, ball-on-disk, block-on-ring, reciprocating wear, rotary wear, scratch, indentation, four-ball, tension/compression, variable rolling-to-sliding, tribocorrosion, and more. Drives can be changed quickly without tools.

The system supports up to 200 kHz data acquisition and up to 8 or 16 synchronized channels, depending on configuration. Real time control, visualization, and analysis are provided in the TriboScript software.

Yes. Dedicated liquid containers are available for rotary and reciprocating drives. A tribocorrosion electrochemical module is available for three-electrode testing with controlled temperature up to 80°C.

Available sensors include acoustic emission (0.2 to 5 MHz), electrical contact resistance (from mΩ to MΩ), temperature sensors (Type-K up to 1000 °C, RTD up to 150°C), capacitance for micro-wear and deformation, and torque and multi-axis sensors.

Nearly 40 ASTM methods can be demonstrated on UMT TriboLab, including G99, G132, G77, D4172, and many others. Contact us to discuss capabilities with regards to specific standards.

More About Bruker's Mechanical Testing and Tribology Technology

TriboLab platforms support standard rotary, reciprocating, block-on-ring, four-ball, scratch, and indentation tests. Common methods include ASTM G99, G133, G77, D4172, and C1624. Equivalent ISO methods can typically be addressed through the same hardware and scripting.

The exact scope of the included installation and operator training depends on region and contract. Confirm details with your Bruker representative.

All TriboLab systems are modular. You can select drives, force and torque sensors, environmental chambers for temperature and humidity, liquid and electrochemical options, and advanced sensors to meet your application needs. If you are not sure which modules meet your needs, our experts can help.

Bruker provides applications consulting, troubleshooting, and best practice guidance, along with optional service plans for ongoing support, maintenance, and training.

Contact us to arrange a demonstration or submit samples for an evaluation tailored to your test geometry and materials.