UMT TriboLab

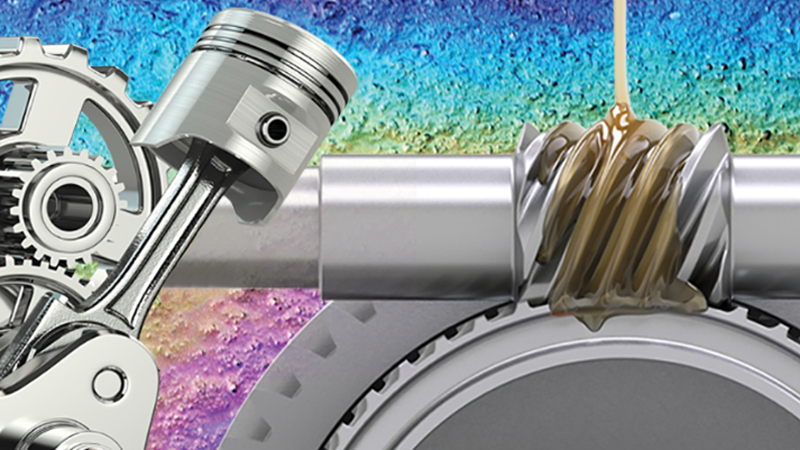

布鲁克通用机械测试仪 (UMT) 平台自 2000 年推出第一款型号以来,一直是市场上功能全、使用广泛的摩擦仪。现在,新设计的UMT TriboLab™基于多功能的设计传统构建,具有独特的模块,实现了比以往更多的功能,在性能方面没有任何降低。事实上,UMT TriboLab 比竞争对手提供更高的速度、更多的扭矩和更好的力测量。此外,它还引入了强大的新功能,提高了效率和易用性。

- 出色的模块化 - 可适应各种速度和扭矩,几乎执行所有可能的摩擦学测试。

- 广泛的能力 - 模拟最广泛的环境,实现前所未有的测试范围。

- 灵活的易用性 - 无需学习复杂的脚本语言或编程。

To learn more, continue reading, contact us, or see FAQs about this product.

模块化驱动器,实现更多功能

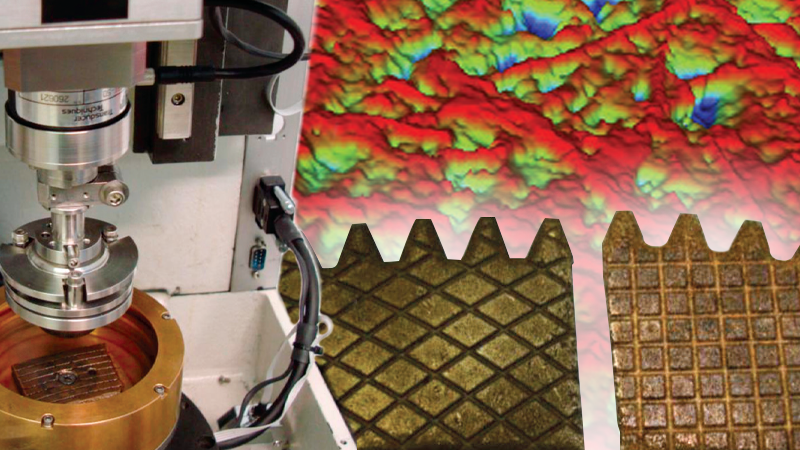

使用专利免工具安装方法可以快速更换驱动器,用户可以轻松安装驱动器,然后在数秒内锁定。标准驱动器不需要电缆连接,安装环上的盲配连接器会自动连接风扇、传感器和其他电子设备。每个硬件组件都包含一个 Tribo ID 芯片。软件会询问系统,解释芯片,并在没有操作员输入的命令的情况下"理解"配置。

Easy and reliable high- and low-temperature testing in industrial applications

Temperature significantly influences wear and friction behavior of materials. The UMT TriboLab™ platform can be equipped with temperature chambers that allow testing up to 1200°C* and down to -40°C. With options available for both the rotary and reciprocating drives, these chambers enable easy, reliable temperature-controlled testing for many demanding research and industrial applications.

*High temperature testing chambers not yet available for sale in Europe.

高负载、高性能传感器

UMT TriboLab 利用布鲁克传感器技术的最新发展,生成高精度和可重复的测试数据。这些新型"黄金系列"传感器具有业界领先的 0.02% 量程的噪声水平。电路经过全面重新设计,将噪声降至更低。传感器的范围也扩展到11个传感器,从1毫牛到2千牛的力量。

易于进行全面测试和报告

通过内置于设备硬件上的Tribo ID芯片,软件自动"理解"硬件配置,菜单只显示当前可用的功能。TriboScript 利用图标化的用户界面,只需将图标拖到工作区即可生成测试脚本。只有兼容的图标系统才会将其合成在一起,然后提示所需的变量,如速度或力。TriboScript 还预加载了许多常用的标准测试方法,如 ASTM、DIN、JIS 等。最后,对于测试后分析和报告,只需选择要考虑的数据通道,软件将同步显示结果,以全面了解测试期间发生了什么。

针对专业应用的行业特定解决方案

布鲁克利用TriboLab平台的多功能性和模块化架构,为特定应用和行业创建“交钥匙”套件。除了量身定制的硬件组件外,这些模块还含有与行业领先的制造商一起开发的软件,以满足客户测试标准的要求。布鲁克的行业特定解决方案包括制动材料筛选、离合器摩擦材料筛选、HFRR 测试、3 点弯曲测试和高温硬度测试等等。

Frequently Asked Questions

UMT TriboLab supports heating up to 1200 °C (availability may vary by region), cooling down to −40 °C with the optional chiller kit, and humidity control from 5 to 85% relative humidity.

The system supports a force range from 1 mN to 2 kN, torque up to 5 N∙m at 100 rpm (2.5 N∙m at 5000 rpm), rotary motion up to 5000 rpm, and reciprocating motion up to 60 Hz.

Available configurations include pin-on-disk, ball-on-disk, block-on-ring, reciprocating wear, rotary wear, scratch, indentation, four-ball, tension/compression, variable rolling-to-sliding, tribocorrosion, and more. Drives can be changed quickly without tools.

The system supports up to 200 kHz data acquisition and up to 8 or 16 synchronized channels, depending on configuration. Real time control, visualization, and analysis are provided in the TriboScript software.

Yes. Dedicated liquid containers are available for rotary and reciprocating drives. A tribocorrosion electrochemical module is available for three-electrode testing with controlled temperature up to 80°C.

Available sensors include acoustic emission (0.2 to 5 MHz), electrical contact resistance (from mΩ to MΩ), temperature sensors (Type-K up to 1000 °C, RTD up to 150°C), capacitance for micro-wear and deformation, and torque and multi-axis sensors.

Nearly 40 ASTM methods can be demonstrated on UMT TriboLab, including G99, G132, G77, D4172, and many others. Contact us to discuss capabilities with regards to specific standards.

More About Bruker's Mechanical Testing and Tribology Technology

TriboLab platforms support standard rotary, reciprocating, block-on-ring, four-ball, scratch, and indentation tests. Common methods include ASTM G99, G133, G77, D4172, and C1624. Equivalent ISO methods can typically be addressed through the same hardware and scripting.

The exact scope of the included installation and operator training depends on region and contract. Confirm details with your Bruker representative.

All TriboLab systems are modular. You can select drives, force and torque sensors, environmental chambers for temperature and humidity, liquid and electrochemical options, and advanced sensors to meet your application needs. If you are not sure which modules meet your needs, our experts can help.

Bruker provides applications consulting, troubleshooting, and best practice guidance, along with optional service plans for ongoing support, maintenance, and training.

Contact us to arrange a demonstration or submit samples for an evaluation tailored to your test geometry and materials.