Heavy Mineral Sands, Frack Sands, and Silica Sand

Mineral Sands: Innovative Analysis of Small Grains with Big Importance

Rare and valuable, heavy mineral sands provide resources that are critical to the modern economy. Heavy mineral sands are paleo dune, beach, or river deposits enriched in high density minerals such as ilmenite, zircon, leucoxene, monazite and rutile. Less commonly garnet, magnetite, sapphire, diamond and staurolite are also mined from heavy mineral sand deposits. The natural hydrodynamic processes of ancient environments sorted sands by density,which can also be seen on modern beaches as dark sand layers. Heavy mineral sands are used as raw feedstocks in industrial processes and as products themselves. Zircon is used for control rods in nuclear reactors. Rutile is the primary source of titanium for white paints. Some sand is also used as proppant for hydraulic fracturing in oil and gas wells and as a source of high-purity silicon. The possibility of extracting rare earth elements from mineral sands is being actively explored.

All industrial mineral utilization of sand deposits relies on reliable chemical and textural classification of deposits. Bruker has partnered with industry leaders and government research institutes to pioneer new methods for heavy mineral sands assessment, grade control for sand projects, and process control during sorting and processing.

Elemental Assay with X-ray Fluorescence

X-ray fluorescence spectroscopy (XRF) provides one of the key methods for elemental assay of mineral sands for quality assessment and grade control. Elemental analysis of heavy mineral sands is a critical step in certifying prospectivity of discoveries and confirming grade in product streams. Bruker’s elemental analyzers can be calibrated with matrix-matched calibrations to specific deposits and customized to meet the need of any analytical workflow. From portable analyzers at the excavation site to central laboratory analysis, Bruker is your partner for analytical success.

Explore XRF Options

| S1 TITAN 800 | Portable XRF | Portability and power define the S1 TITAN, with a rugged case, Titan Detector Shield™ and GeoExploration calibration. Portable XRF is ideal for on-site analysis, exploration, and core scanning. |

| CTX | Countertop XRF | The CTX is a rugged and portable single-sample countertop XRF with battery backup, safety interlocked lid, Titan Detector Shield™ and push-button operation that is ideal for quick-look grade control and process control. |

| S2 PUMA | Benchtop ED-XRF | The S2 PUMA Series 2 is the standard for laboratory ED-XRF analysis, equipped with the intuitive TouchControl™ interface and XY robotic multi-sample or carousel sample changer. |

| S6 JAGUAR | Benchtop Sequential WD-XRF | The S6 JAGUAR provides WD-XRF performance in a compact package ideal for any laboratory analysis. |

| S8 TIGER | Sequential WD-XRF | The S8 TIGER Series 2 sequential WDXRF provides outstanding superior analytical performance for the most demanding mineral and mining applications. |

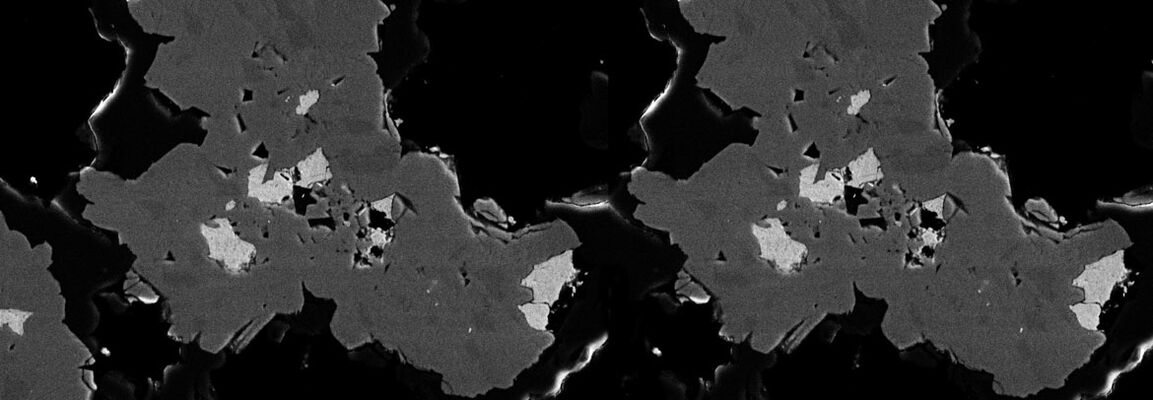

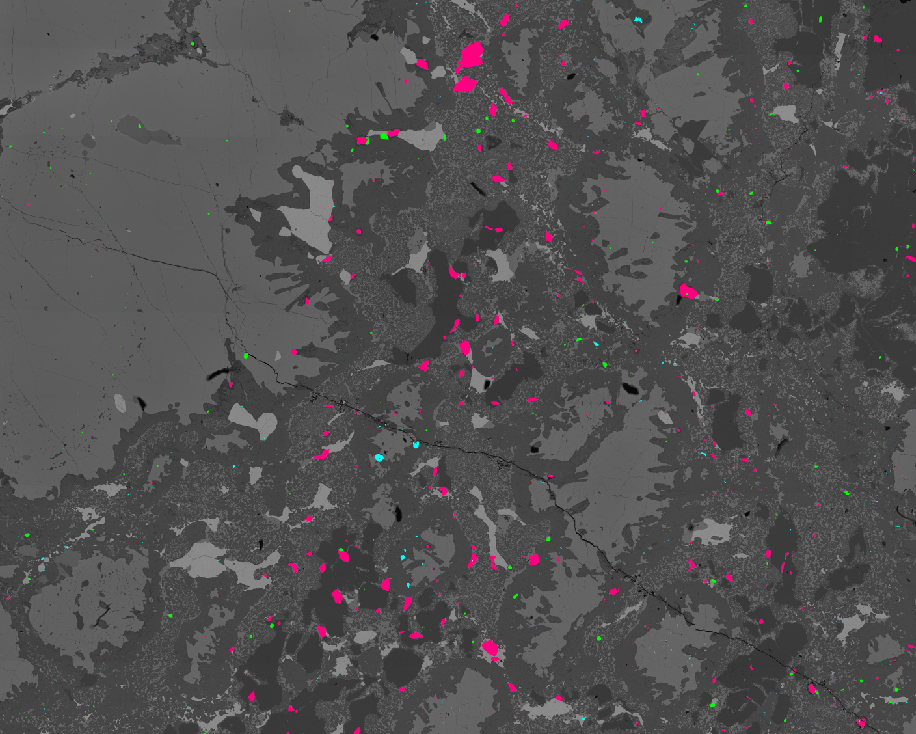

Save Energy by Calculating the Degree of Liberation

The comminution process is one of the most energy intensive phases in the mining value chain. Mineral liberation analysis is used to optimize this process by calculating the degree of liberation of a sample. Liberation is the degree of freedom of a target mineral phase from its surrounding matrix. Automated mineralogy combines Scanning Electron Microscopy (SEM) with energy dispersive spectroscopy (EDS) to quickly and accurately quantify mineral texture in samples and calculate the degree of locking or liberation for a target mineral. Bruker AMICS automated mineralogy platform is leading the industry with recent advances in the price and usability of both the software and application on compact or desktop SEMs; Automated mineralogy is now accessible to any sized operation.

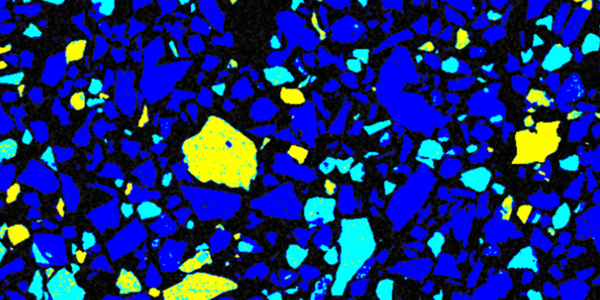

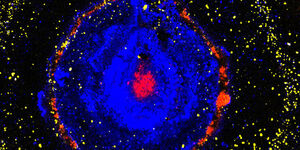

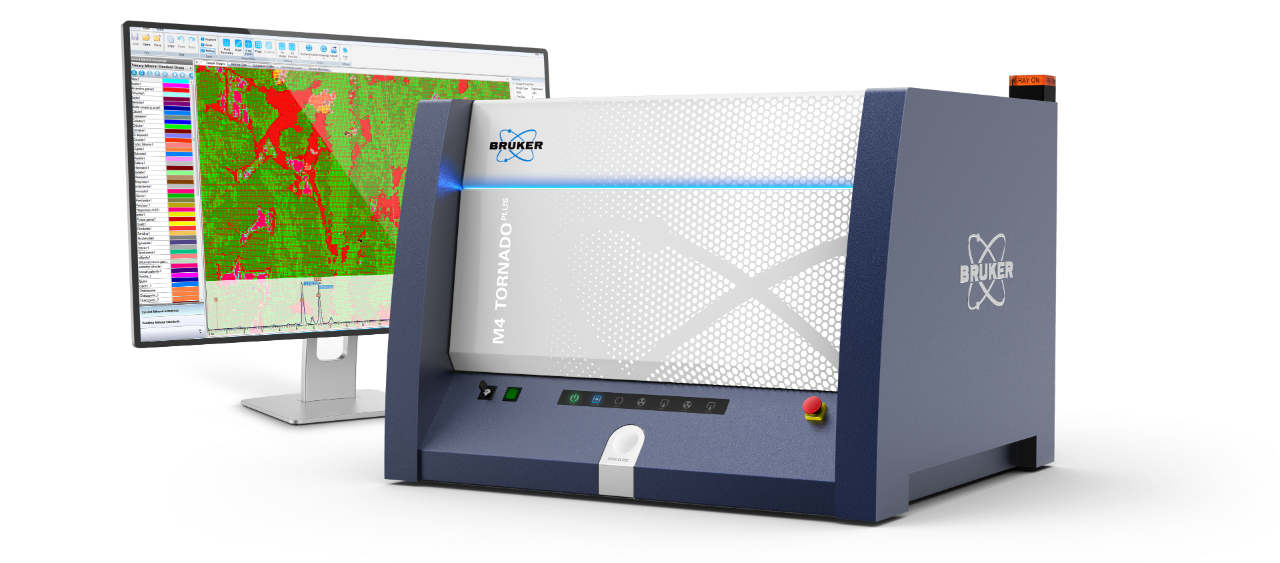

A New Automated Chemical and Mineral Mapping Method for Analysis of Mineral Sands

Grades for economic deposits of heavy mineral sands are low, with typical values of target mineral grains between 1% and 3%. This complicates exploration, as the low-grade peripheries of deposits may be below the detection limit of XRF or XRD. The uniqueness of each deposit requires specific approaches to processing, commonly requiring complex arrays of density separation equipment. Detailed optical or chemical characterization of sediment texture becomes an important factor in exploration, processing plant design, and ongoing grade control and deposit management. Micro-XRF is emerging as new method for quick-look mineral identification and textural assessment. Some key features of this method:

The M4 TORNADO is used to collect an elemental map of the sample. An X-ray beam of ~18µm is used to map representative samples that have been scattered on carbon tape. No epoxy, polishing, or carbon coating is required

X-ray maps can be quantified and used to calculate a pseudo-bulk concentration or the percent abundance of individual mineral grains

The M4 TORNADO AMICS automated mineralogy software may be implemented to match X-ray point measurements to minerals. A generated mineral map can be used to calculate modal mineralogy, grain size abundance by mineral, and other properties.

Publications Related to Heavy Mineral Sands

- 2020 - Mining, Metallurgy & Exploration: Chemical and Mineralogical Characterization of Malaysian Monazite Concentrate

- 2019 - Geochemistry: Exploration, Environment, Analysis: The application of pXRF for the chemical and mineralogical characterization of heavy mineral sands

- 2017 - Geochemistry: Geochemistry of coastal sands of Eastern Mediterranean: The case of Nisyros volcanic materials