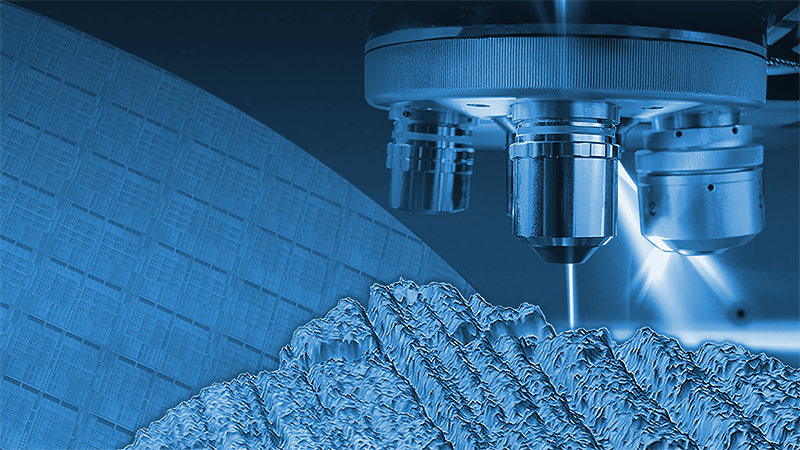

Accelerating Semiconductor Processes Control with Advanced 3D Optical Metrology

Increastingly strict tolerances make fast, precise front- and back-end process control a critical part of semconductor device and component production.

This webinar presents case studies demonstrating the use of 3D optical profilers for improving yield, identifying root cause failure, and driving next-generation device development from bare wafer to final packaged device.

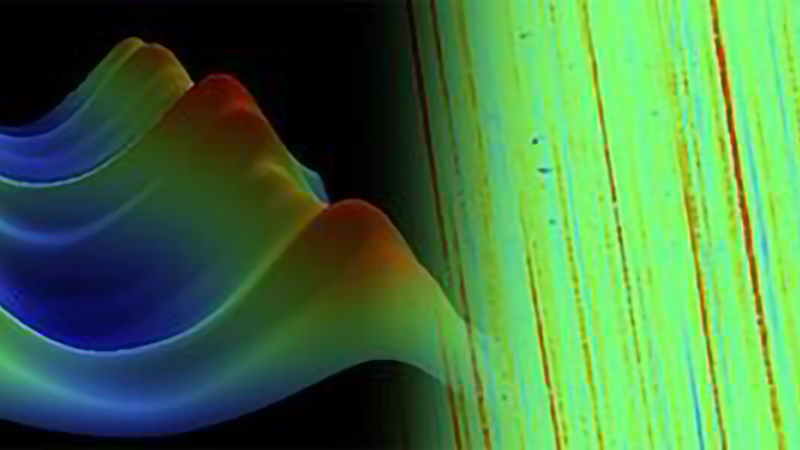

Viewers can expect to gain new insight into bare wafer roughness control and CMP monitoring and optimization as well as the use of direct measurement of topography to assess die flatness and identify the source of RDL, bump, recess, and overlay defects.

Webinar Summary

Explore Advanced Process Control Techniques for Semiconductor Manufacturing

Designed for Process, CMP, and Metrology & Quality Engineers as well as R&D scientists working in semiconductor, micro-electronics, display technology, printed electronics, and telecoms industries, we cover requirements and metrology needs for:

- Advanced telecommunication

- Compact on-board electronics

- Electric vehicles

- Denser interconnect networks

- Finer redistribution layer (RDL)

- Direct wafer to wafer bonding

- Wafer fan-out packaging

Among the included case studies, front end (FEOL) examples will include:

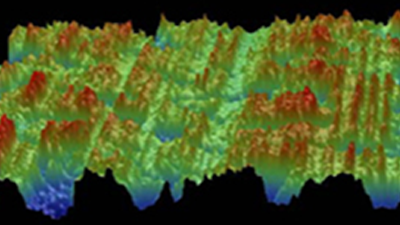

- Wafer bin roughness and edge roll-off

- CMP efficiency full die flatness

- CD metrology including TSV, deep trench RIE (Bosch process)

- Epi layer defect quantification in high power devices

Back end (BEOL) and packaging examples will address:

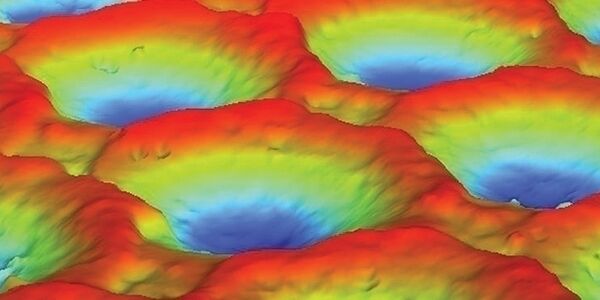

- Under Bump Metallization (UBM)

- Recess defect inspection

- Full die screening for dense interconnect control

This webinar was presented on December 17, 2018.

Find out more about the technology featured in this webinar or our other solutions for semiconductor process control:

Featured Products and Technology

Speakers

Samuel Lesko, Ph.D.

Dir. of Technology and Apps Development for Tribology, Stylus & Optical Profilers, Bruker

Samuel Lesko has over 20 years of optical and stylus profiler applications experience, particularly in using white-light interferometry in a wide variety of fields, from MEMS and semiconductor to automotive and aerospace. He is a member of SME and part of ISO/TC 213/WG committee (areal roughness) and obtained his physics Ph.D. and material science engineering degree at the University of Burgundy in France.