MPA III

FT-NIR Multi Purpose Analyzer

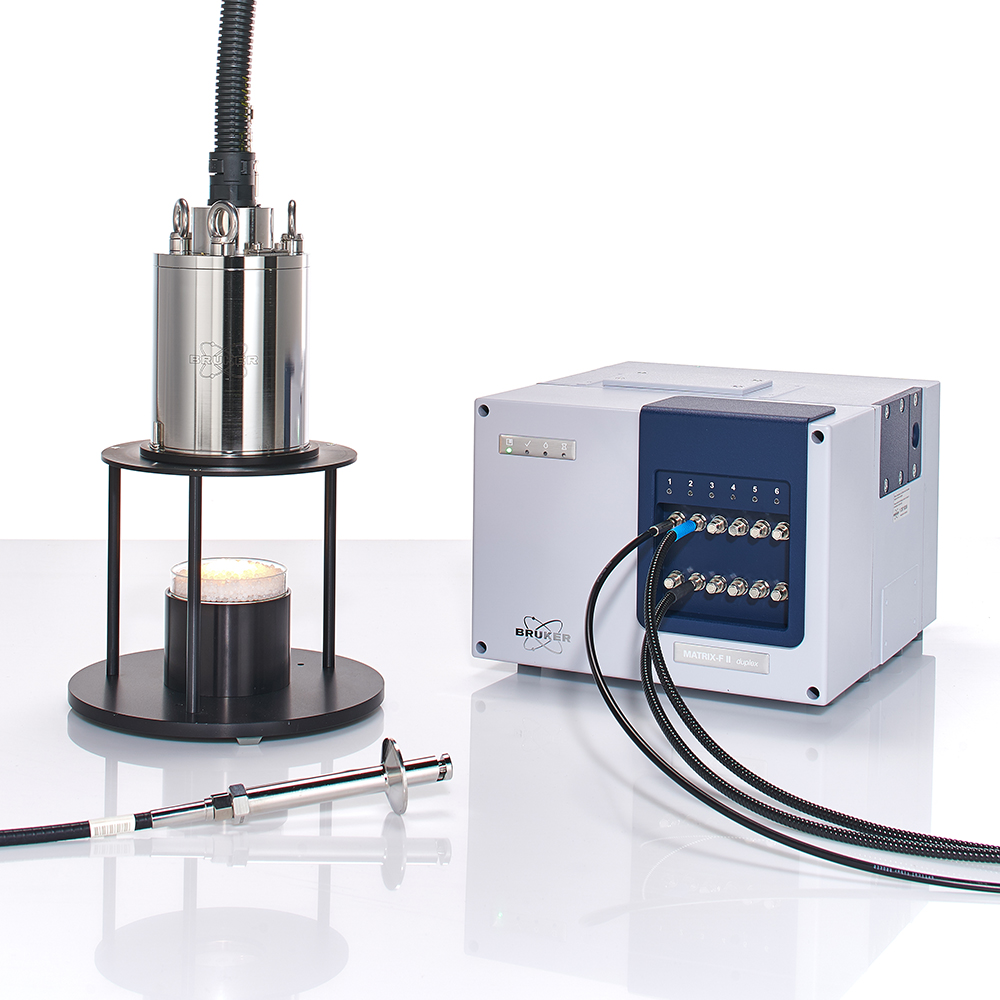

MPA III: The FT-NIR Multi Purpose Analyzer

Choosing the best possible sampling method is crucial when solving a specific analysis task. With the MPA III, you have a complete solution at hand for your daily QA/QC work, but also for sophisticated method development studies. Initially it is often not obvious which sampling method is the best. With the MPA III, simply try out several methods choose the best option for you. The possibilities are endless, and due to the modular design of the MPA III, the instrument can easily be adapted to your needs. The robustness of the instrument allows it to be used in the laboratory and factory floor.

Initially it is often not obvious which sampling method is the best. With the MPA III, simply try out several methods choose the best option for you.

The possibilities are endless, and due to the modular design of the MPA III, the instrument can easily be adapted to your needs. The robustness of the instrument allows it to be used in the laboratory and factory floor. It can even be placed on a utility cart for mobile applications.

Easy Operation

Customizable workspaces as well as easy measurement modes which guide you through the setup of analytical methods are standard in the OPUS spectroscopy software. Measurements can be started with a mouse click or at the touch of a button.

The smart display informs the user about the instrument status and the measurement. These factors make the operation of the instrument and the software so easy that even untrained personnel can operate the MPA II spectrometer from day one.

State-of-the-art Technology

The MPA III incorporates state-of-the-art optical parts for outstanding performance and stability:

- Long-life light source for enhanced robustness and reduced maintenance costs.

- Durable solid state laser for highest wavenumber accuracy.

- Permanently aligned RockSolid™ interferometer, equipped with gold-coated cube-corner mirrors for consistent high quality results, less downtime and highest stability.

- High-sensitivity InGaAs detectors with linear response over the complete wavenumber range for highest accuracy and reproducibility.

All optical components installed in the MPA III are permanently monitored by the online diagnostic system, which makes sure that your spectrometer operates correctly. Whenever a component is out of specification, the user is notified immediately.

We are convinced of the exceptional quality by design of our MPA III FT-NIR spectrometers.This is why we grant 10 years warranty on the moving parts of the interferometer as well as on the solid state laser.

Hassle-Free Maintenance

MPA III spectrometers are designed to be easily main-tained by the user, thereby decreasing downtime and maintenance costs. Consumable items such as the light source are designed for a long life, but if they need to be replaced, the system automatically informs the user of the failure and offers online help for the replacement procedure. The consumables are prealigned and can be easily and quickly changed.

Moreover, the Ethernet access to the MPA III allows remote control and diagnostics of the spectrometer via your intranet or the World Wide Web.

Validation

The MPA III FT-NIR spectrometer features an internal filter wheel (‘validation unit’) that houses reference materials (e.g. BRM 2065) and several filters for automated instrument qualification tests. The OPUS Validation Program (OVP) is an intuitive user interface to setup and perform OQ and PQ protocols that verify that the MPA III is operating within specifications – also in routine use.

A wide range of external reference materials, e.g. SRM 1920, SRM 2065 and Labsphere standards, is supported. OVP fulfils the requirements of current guidelines, e.g. USP, JP and Ph. Eur., and always keeps the user updated on the instrument status.

The ‘Validation Manual’ provides the comprehensive documentation of instrument qualification and software validation including the corresponding certificates.

User-friendly Software

Additional OPUS packages for routine measurements and evaluations can be added as required:

- OPUS/LAB is an intuitive and easy-to-use software interface for conducting routine analysis tasks. The software guides you through the workflow from the measurement to the evaluation result and report.

- OPUS/IDENT offers reliable identification of all raw materials with one hierarchical library. Method setup including statistical evaluation, internal validation and use of the identification library, can be performed in a few easy steps.

- OPUS/CONFO determines the conformity of a given material by looking at the spectral variation between different lots of materials which have been determined acceptable for the manufacturing process and an unknown sample at each spectral data point.

- The OPUS/QUANT2 software for multivariate calibration and validation is based on the common algorithm PLS (Partial Least Squares). The setup includes many useful plots, statistics and tools making your method development less time consuming and an automated optimization tool to find the parameters for the potentially best model.

- The Multi Evaluation functionality in the OPUS software allows the combination of various evaluation functions as well as the calculation of formulae using OPUS/QUANT2 predictions.

All methods created on the MPA II are fully reproducible and transferable to other comparably equipped Bruker Optics spectrometers - even for online applications - due to the superior mechanical precision and outstanding stability of our instruments. - The ONET software is a web based application to setup, administrate and control a network of FT-NIR instruments from anywhere in the world. All data measured locally on the spectrometers are pooled and centrally stored.

GMP and 21 CFR Part 11 compliance

As a single platform interface, OPUS spectroscopy software entirely complies with current practice guidelines, featuring an extensive user management with multiple customizable access levels, complete audit trail, password protected databases and a single file strategy for easy data archiving. In ‘validated mode’ all demands of 21 CFR Part 11 (Electronic Records, Electronic Signatures) are covered by a smart signature strategy for measurement files and evaluation methods.

For all your Application Needs

The multitude of sampling modules and accessories make the MPA III the ultimate FT-NIR solution for various types of industries.

The main benefit of FT-NIR spectroscopy is its versatility and ease of use. It is a fast and precise tool for the non-destructive analysis of liquid, solid and semi-solid materials, saving costs by reducing time and reagent use. It has largely replaced a number of wet chemical analysis methods in all types of industries including the food and fed industry as well as the chemical an pharmaceutical industry.

The comprehensive application support of the Bruker specialists helps to select the optimal measuring method as well as appropriate accessories and software solutions.

The most important applications are:

- Testing of incoming raw materials

- Process-accompanying analytics

- Final product inspection

- Release analytics

FT-NIR Solutions for the Food and Agri Industry

The major application areas for the MPA III in the food and feed industry include dairy and meat, beverages, edible oils, bakery ingredients and condiments as well as grains, seeds, feed and forage.

FT-NIR Solutions for the Pharmaceutical Industry

Use FT-NIR to effectively and cost efficiently solve a huge variety of application tasks in the pharmaceutical and cosmetics industry, including raw material ID, tablet testing and monitoring drying or blending processes.

FT-NIR Solutions for the Chemical and Polymer Industry

FT-NIR technology is widely used in a variety of chemical industries, including the petrochemical and polymer industry. The high information content in NIR spectra, measured in a few seconds, allows the simultaneous analysis of different components and system parameters with high precision.

FT-NIR Literature Room

Learn more about our FT-NIR products and solutions by downloading related literature.

Application Support

Bruker Optics is staffed by expert scientists and engineers who have an in-depth know-ledge of instrumentation and applications. Our product specialists are available to assist you with method development either remotely or in your lab.

Moreover, Bruker Optics offers an array of ready-to-use calibrations which facilitate your entry into the world of NIR spectroscopy.

Service & Training

Bruker Optics spectrometers are designed to provide years of dependable trouble-free operation, but should a problem occur a network of Bruker companies and representatives throughout the world are ready to promptly respond to your needs. Professional installations and a high standard of post-delivery service are commitments Bruker Optics makes to each of its customers. Remote diagnostics in addition to a variety of service contract packages are available for comprehensive support.

Apart from regular customer trainings, dedicated in-house seminars and local support can be arranged according to your needs.