XPM: High Speed Nanoindentation and Mechanical Property Mapping

Explore XPM high-speed nanoindentation mapping and its application potential

Nanoindentation has traditionally produced a low volume of data, leading to small tested areas and difficulty producing statistically relevant datasets. XPM high-speed nanoindentation mapping enables large amounts of data to be collected in a short amount of time.

In this webinar, Bruker Applications Scientist Dr. Eric Hintsala presents:

- An introduction to nanoindentation and nanomechanical property mapping

- Considerations and best practices for high-speed nanomechanical property mapping

- Applications for mapping microstructural features and interfaces

- Applications for using high mapping speeds to facilitate statistical analysis and temperature ramps

Webinar Summary

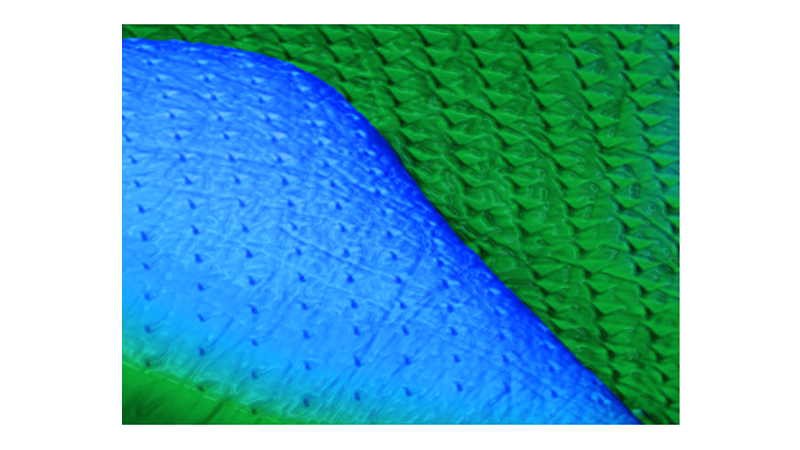

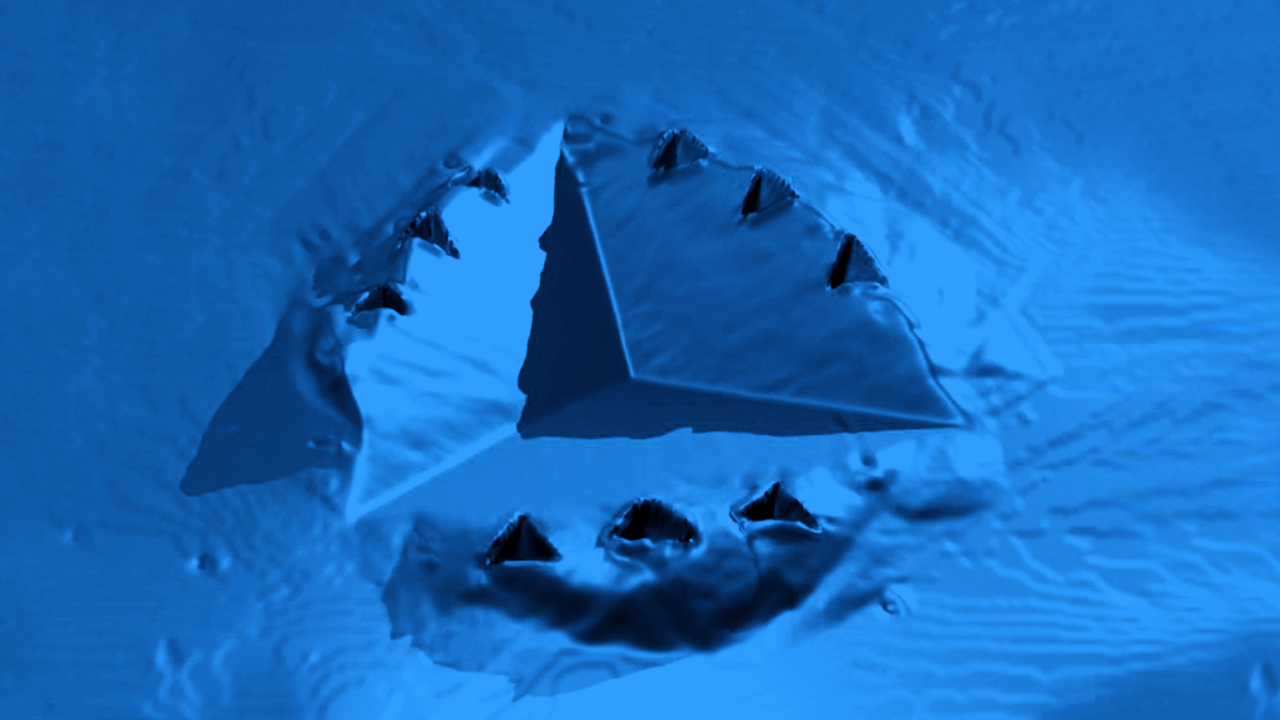

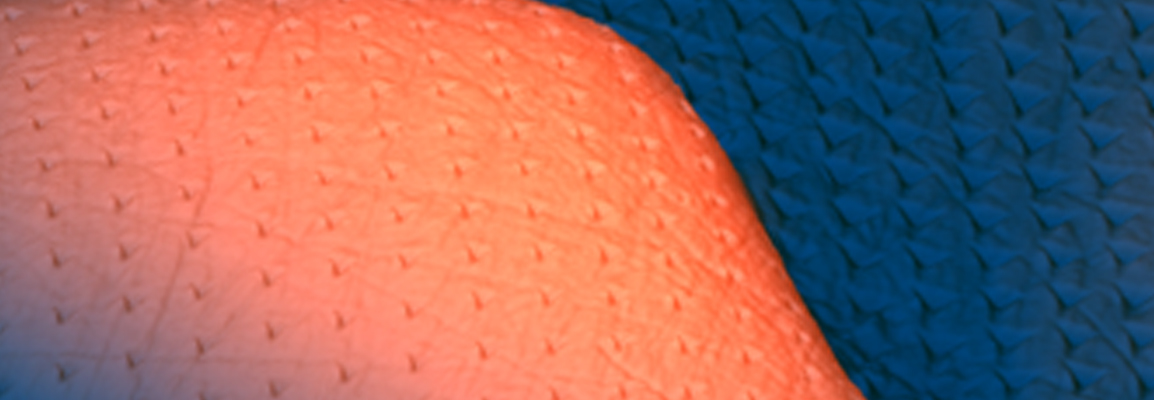

Nanoindentation techniques have long had an important role in quantitatively evaluating the mechanical properties of microstructural features. High-speed nanoindentation mapping techniques have recently achieved speeds up to 6 indents/second, approximately 500x faster than traditional nanoindentation mapping methodologies. This enables a one-to-one correlation with other techniques (such as EBSD) and provides large data sets for robust statistical analysis. This correlation can produce high resolution structure-property relationships which can be mapped over sub-micron to several hundreds of micron length scales

During this webinar, Eric Hintsala, Ph.D. (Bruker), first gives an overview of nanoindentation and of how XPM (accelerated property mapping) operates, discussing the advantages and disadvantages of XPM compared to standard nanoindentation. He then moves to practical aspects of the measurement – setting up a load function, choosing measurement parameters, and analyzing the resulting XPM data.

Dr. Hintsala gives specific case study examples to showcase the value of XPM in:

- Evaluation of microstructure-property evolution during processing

- Quality control testing of weld zones

- Evaluation of sub-surface damage gradients (wear, corrosion, irradiation)

- Investigation of composite material interfaces

He then answers several questions from the audience about XPM capabilities.

Find out more about the technology featured in this webinar or our other solutions for High Speed Nanoindentation:

Featured Products and Technology

Speaker

Dr. Eric Hintsala

Applications Scientist

Dr. Eric Hintsala is a Materials Scientist, with a B.S. from Michigan Technological University and Ph.D. from the University of Minnesota. Dr. Hintsala's background is in mechanical properties of materials, nanomechanical testing techniques, and electron microscopy. Dr. Hintsala is part of R&D at Bruker NI, where he develops advanced instrumentation and testing techniques. Topics of particular interest include in situ testing, elevated temperature “in operando” testing and high speed nanoindentation mapping.