Deep Learning to Establish Structure-Property Correlations Using AFM Images

More accurately correlate AFM images with bulk mechanical properties.

Machine learning and specifically, deep learning, is a powerful tool to establish the presence (or absence) of such correlations with its ability to flesh out relationships and trends that are difficult to establish otherwise. Watch this webinar to learn how deep learning tools—in this case, convolutional neural nets—can more accurately:

- Correlate AFM images with bulk mechanical properties; and

- Predict flexural and Young’s modulus, ultimate elongation, and impact toughness of impact copolymers.

Contact Us

If you have any questions about these or any of our other solutions, please contact us. You can also follow @BrukerNano on Twitter for event information and updates.

Improving the Accuracy of PeakForce QNM with Deep Learning Tools

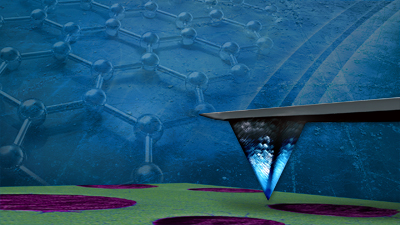

As microscopists, we often hope – and intuit – that the microstructure and local mechanical properties we measure correlate somehow to bulk properties, but this correlation is often difficult to quantify.

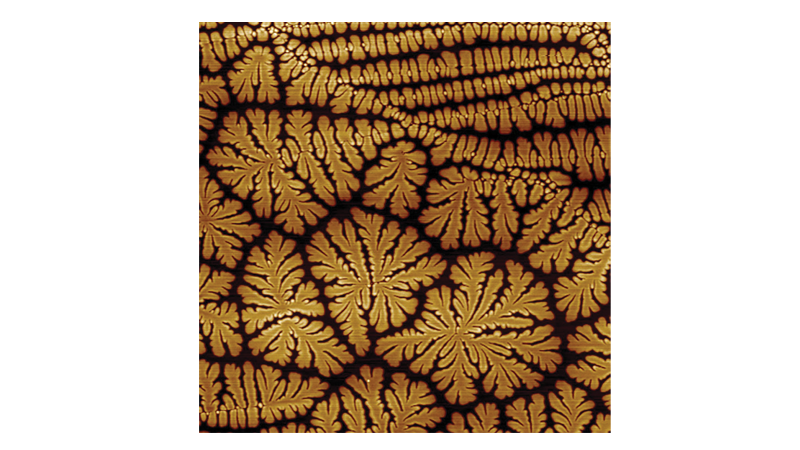

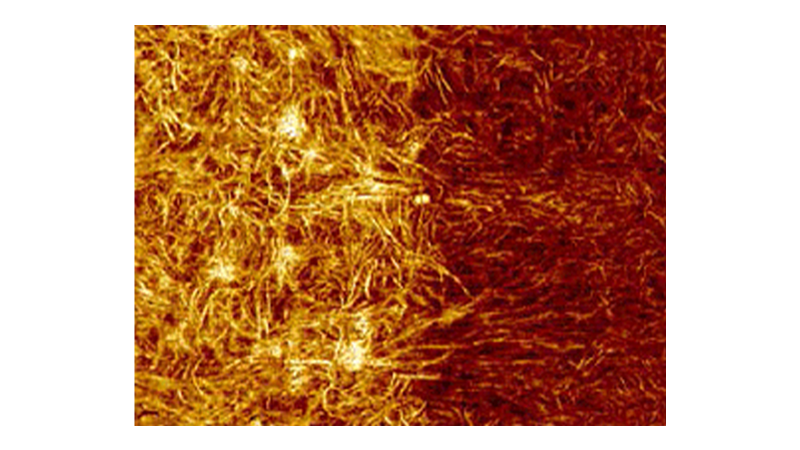

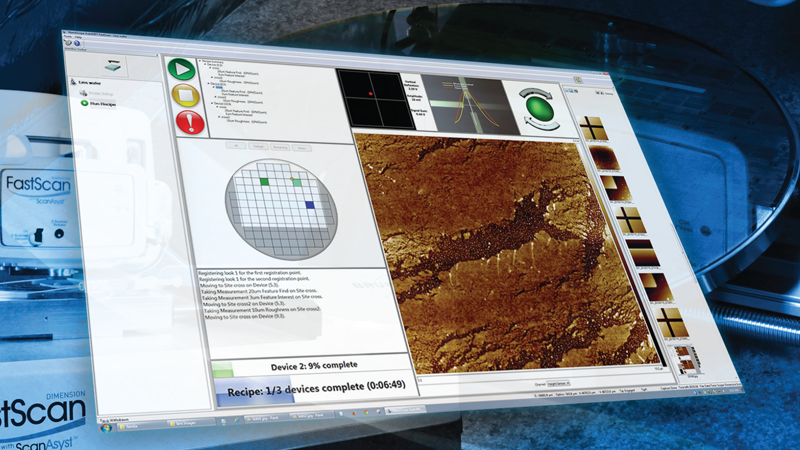

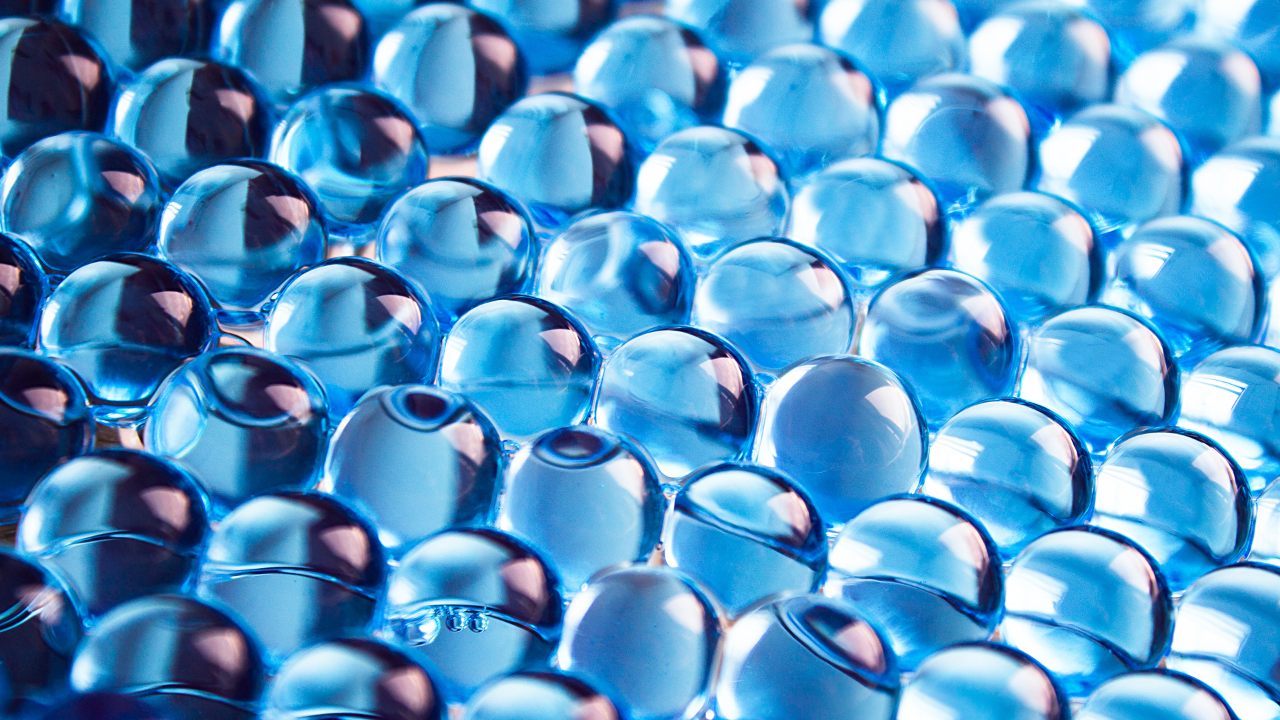

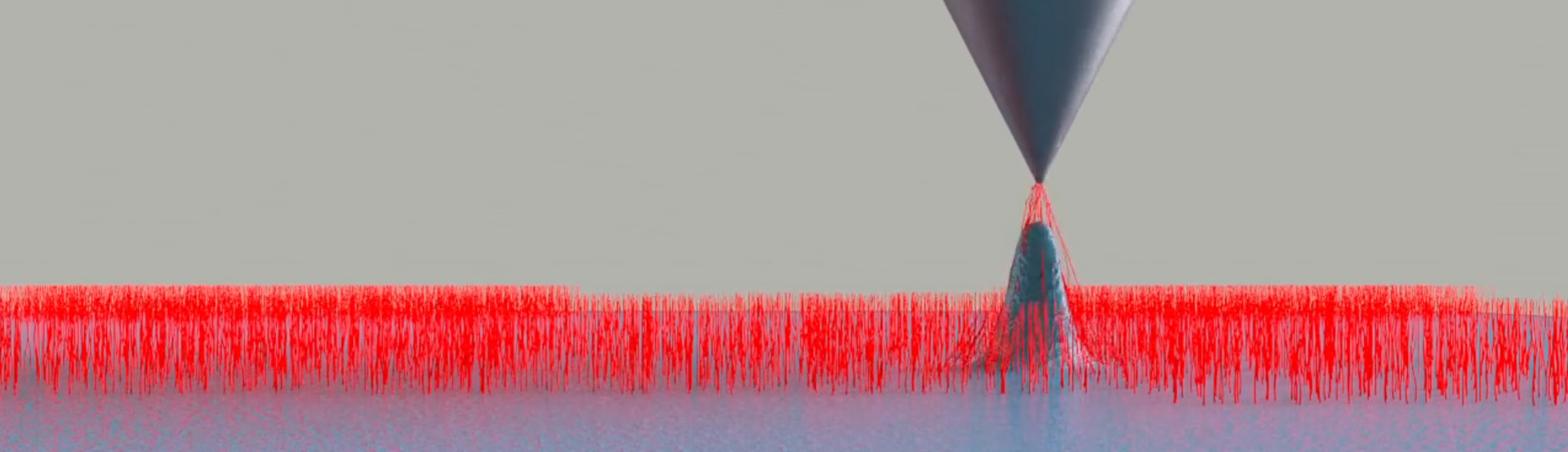

In this webinar, we use deep learning tools such as convolutional neural nets (CNNs) to analyze AFM images of impact copolymers (polymer blends of polypropylene with micro-sized domains of rubber) collected using TappingMode and PeakForce QNM. First, CNNs are used to successfully classify TappingMode phase images of a variety of ICPs where the rubber morphology and distribution vary. The model shows that the PF-QNM deformation channel provides the best accuracy in classification.

Next, we use a regression-based CNN to correlate the AFM images with bulk mechanical properties; both phase images and the PF-QNM deformation channel were used separately in the model. The results show that the deformation data exhibited a superior correlation with the bulk mechanical properties, with high accuracy for predicting flexural and Young’s modulus, ultimate elongation, and impact toughness.

Session Speakers

Dalia Yablon, Ph.D.

Research Chemist, SurfaceChar LLC

Dalia Yablon is the founder of SurfaceChar, an AFM and nanoindentationbased measurement, consulting, and training company in the Greater Boston area since 2013. Dalia also serves as the senior advisor of TechConnect Ventures and Technical Chair of TechConnect World. In addition to editing a book on “SPM in Industrial Applications” (Wiley), Dalia’s research focuses on nanomechanical characterization methods and soft material characterization. She holds an A.B. in Chemistry from Harvard University and a Ph.D. in Physical Chemistry from Columbia University.

Ishita Chakraborty, Ph.D.

Stress EngineeringIshita is a mechanical engineer by training. She completed her PhD from the University of Maryland focusing on nonlinear dynamics of cantilevers with applications to AFM. She did her post-doctoral work on multi-frequency AFM at ExxonMobil focusing on bimodal AFM to characterize polymers. She has a very broad research and consulting experience spanning diverse fields of data analytics, structural vibrations, machine learning and material characterization. She works as a consultant at Stress Engineering Services, Inc. in Houston. Her current interests include image and video analysis and using deep learning to add value to different businesses. In her current role she provides solutions to a variety of industrial problems through machine learning as well as and physics-based modeling.

John Thornton,

Senior Application Scientist, BrukerJohn Thornton is a Senior Applications Engineer at Bruker Nano Surfaces with 25+ years of experience in the field of Atomic Force Microscopy (AFM). He learned AFM at North Carolina State University in the 1990s, and then joined Digital Instruments, a pioneering company in early AFM development, and continued with the company through acquisitions by Veeco Instruments, and then Bruker. John has co-authored many scientific publications and developed scanning probe microscopy training courses. Currently, John spends a significant amount of time running AFMs and educating others on techniques. He currently works from his home in Virginia, and from the Bruker AFM applications lab in Billerica, MA.

Bede Pittenger, Ph.D., Sr. Staff Development Scientist, AFM Applications, Bruker Nano Surfaces

Dr. Bede Pittenger is a Senior Staff Development Scientist in the AFM Unit of Bruker's Nano Surfaces Business. He received his PhD in Physics from the University of Washington (Seattle, WA) in 2000, but has worked with scanning probe microscopes for 25 years, building systems, developing techniques, and studying properties of materials at the nanoscale. His work includes more than thirty publications and three patents on various techniques and applications of scanning probe microscopy. Dr. Pittenger's interests span topics from interfacial melting of ice, to mechanobiology of cells and tissues, to the nanomechanics of polymers and composites.