In-Situ Nanomechanical Testing with the Hysitron PI Envision and PI 89

Driving Innovation in Materials Science with Advanced In-Situ SEM Nanomechanical Testing

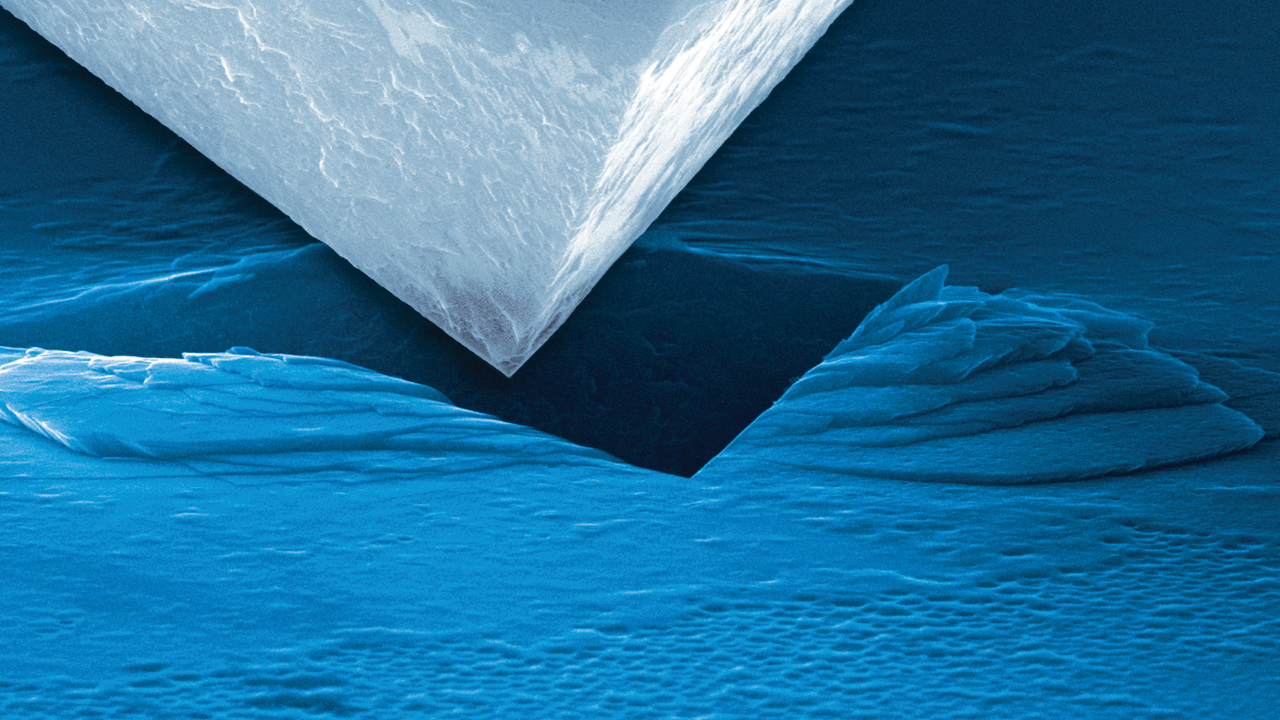

Characterizing site-specific mechanical properties in complex materials is challenging, especially at small scales and in heterogeneous structures. In this webinar, you will learn how the newly launched Hysitron PI Envision SEM PicoIndenter addresses these challenges with sub-nanometer displacement and sub-micronewton force resolution. See how its modular design supports advanced techniques for diverse materials and environments, and discover real-world applications in automotive and nuclear alloy research.

Watch this on-demand webinar for:

- Insights into PI Envision’s design, performance, and modular options

- A live demonstration of PI Envision’s in-situ testing features

- Research from Dr. Tanvi Ajantiwalay (PNNL) using micro compression, micro tensile, micro shear, and nanoindentation on metal alloys to link microstructure to performance

Abstracts

Introducing PI Envision: Precision, Versatility, and Performance Inside Your SEM

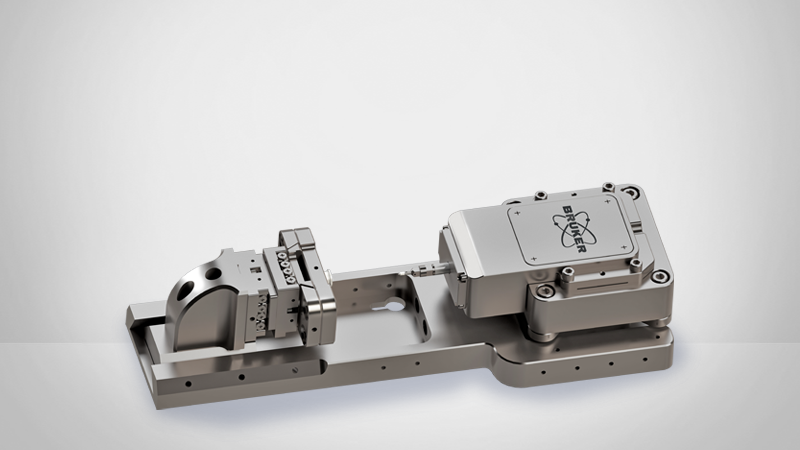

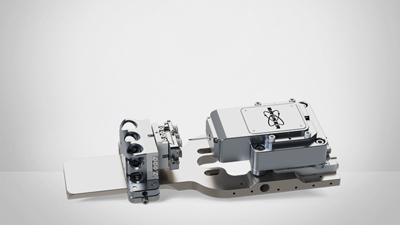

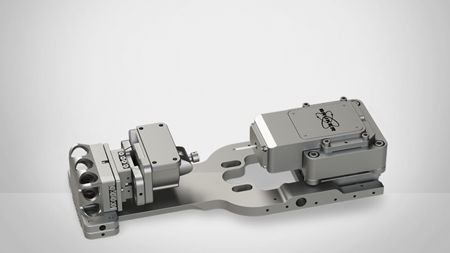

Bruker’s Hysitron PI Envision SEM PicoIndenter is designed for in-situ operation within standard SEMs, FIB-SEMs, small-chamber SEMs, and synchrotron beamlines. With sub-nanometer displacement and sub-micronewton force resolution, PI Envision enables precise analysis of materials ranging from soft polymers to high-strength metals and alloys. This modular and highly upgradable platform supports a comprehensive suite of techniques, including nanoindentation, property mapping, and high-temperature testing up to 800°C. Combining unmatched versatility, precision, and value, PI Envision is ideally suited for multi-user facilities and budget-conscious laboratories.

Correlative Microscopy and Mechanical Testing of Metal Alloys for Automotive and Nuclear Applications

In-situ micromechanical testing provides a powerful means to probe site-specific properties in materials with unique processed zones and heterogeneous grain structures. The reduced length scale enables precise localization of features, cleaner vacuum environments, shorter testing times, and improved statistical reliability. By tailoring specimen geometries, a wide range of mechanical properties can be measured to meet application-specific requirements. In this webinar, Dr. Tanvi Ajantiwalay will highlight the use of micro-compression, micro-tensile, micro-shear testing, and nanoindentation across varying metal alloy systems relevant to automotive and nuclear applications. A correlative approach linking mechanical properties to microstructure through analytical techniques such as EDS and EBSD will also be presented. Together, these methods provide a deeper understanding of localized deformation behavior, thereby supporting the design and optimization of structural materials for demanding service environments.

Featured Products and Technology

Speakers

Materials Scientist, Pacific Northwest National Laboratory

Dr. Tanvi Ajantiwalay is a Materials Scientist in the Energy and Environment Directorate at the Pacific Northwest National Laboratory. Her research interest includes in-situ nano/micro-mechanical testing, solid Phase processing and metallurgy.

Kevin Schmalbach, Ph.D., Instrumentation Scientist, Nanoindentation Unit, Bruker

Kevin earned his PhD in Chemical Engineering from the University of Minnesota in 2022 with his thesis focusing on the study of temperature and strain rate effects in tungsten. He then joined the applications group as a postdoctoral scientist at Bruker, where he developed the PI 89 Auto capabilities. He has recently moved into an instrumentation scientist role in the research and development group, focusing on hardware and technique development for nanoindentation.

Sanjit Bhowmick, Ph.D.

Senior Staff Scientist, Bruker

Dr. Sanjit Bhowmick is a Senior Staff Scientist at Bruker. His research interest includes understanding microstructure and mechanical property correlation of advance nanostructured materials using in-situ SEM and TEM nanomechanical techniques. He has published more than 80 papers in peer-reviewed journals.