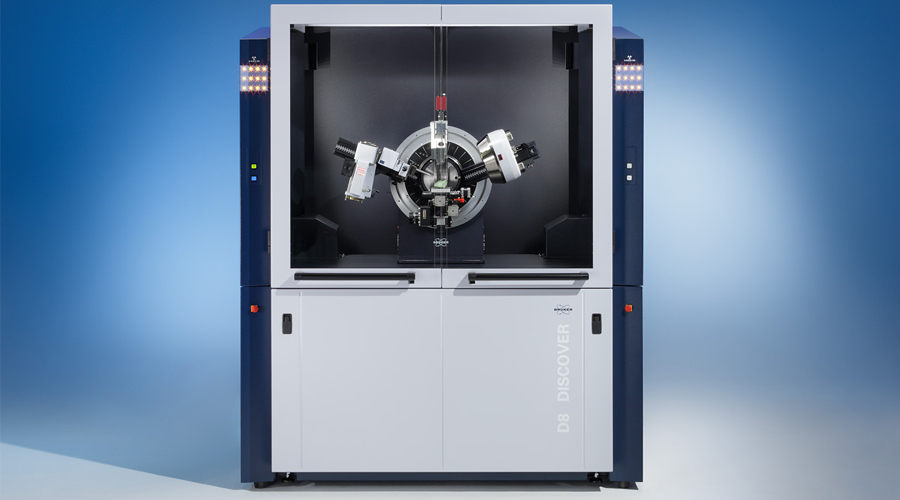

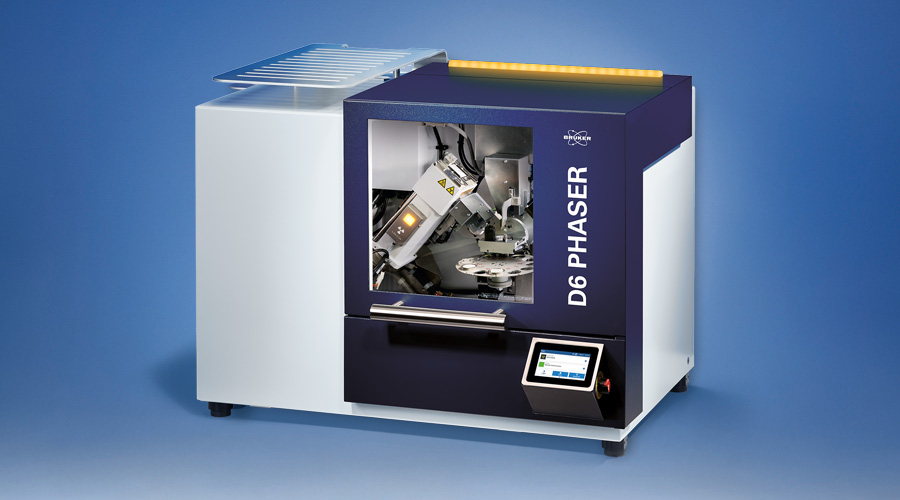

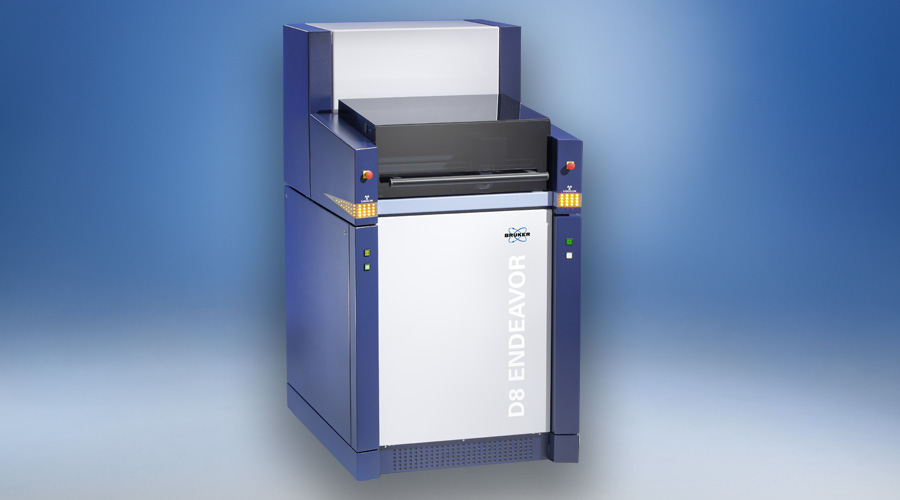

X-ray Diffractometers

Automation

Bruker X-ray diffractometers can be automated using sample robots or conveyor belts.

Our XRD systems offer seamless automation for effortless push-button operation or integration with other laboratory automation solutions. This includes comprehensive sample handling and data evaluation post-measurement. Automation can function in file-based mode, Bruker's proprietary database mode, or with external LIMS software.

Notable examples of automated XRD applications include quantitative phase analysis in the construction materials industry using DIFFRAC.TOPAS BBQ (Black Box Quantification) and pre-defined cement application packages. Other industries benefiting from our solutions include aluminum production and the semiconductor sector.

Our engineering specialists and method developers tailor scripted automation solutions for these industries. Additionally, we provide a variety of tools for workflow evaluation, such as recorded workflows in DIFFRAC.EVA and DIFFRAC.LEPTOS X. Complete streams of evaluation and data handling tasks can be automated using DIFFRAC.BBE (Black Box Evaluation) workflow software.

BAXS Headquarters & other offices & our Virtual Showroom

Visit the demo facilities in our headquarters in Karlsruhe (Germany) or just take a virtual tour on our showroom in Karlsruhe to see and learn more about our analytical solutions. Or take a virtual tour on our showroom in Madison (USA).

If you have any questions, please do not hesitate to contact our team of experts from sales or customer support.