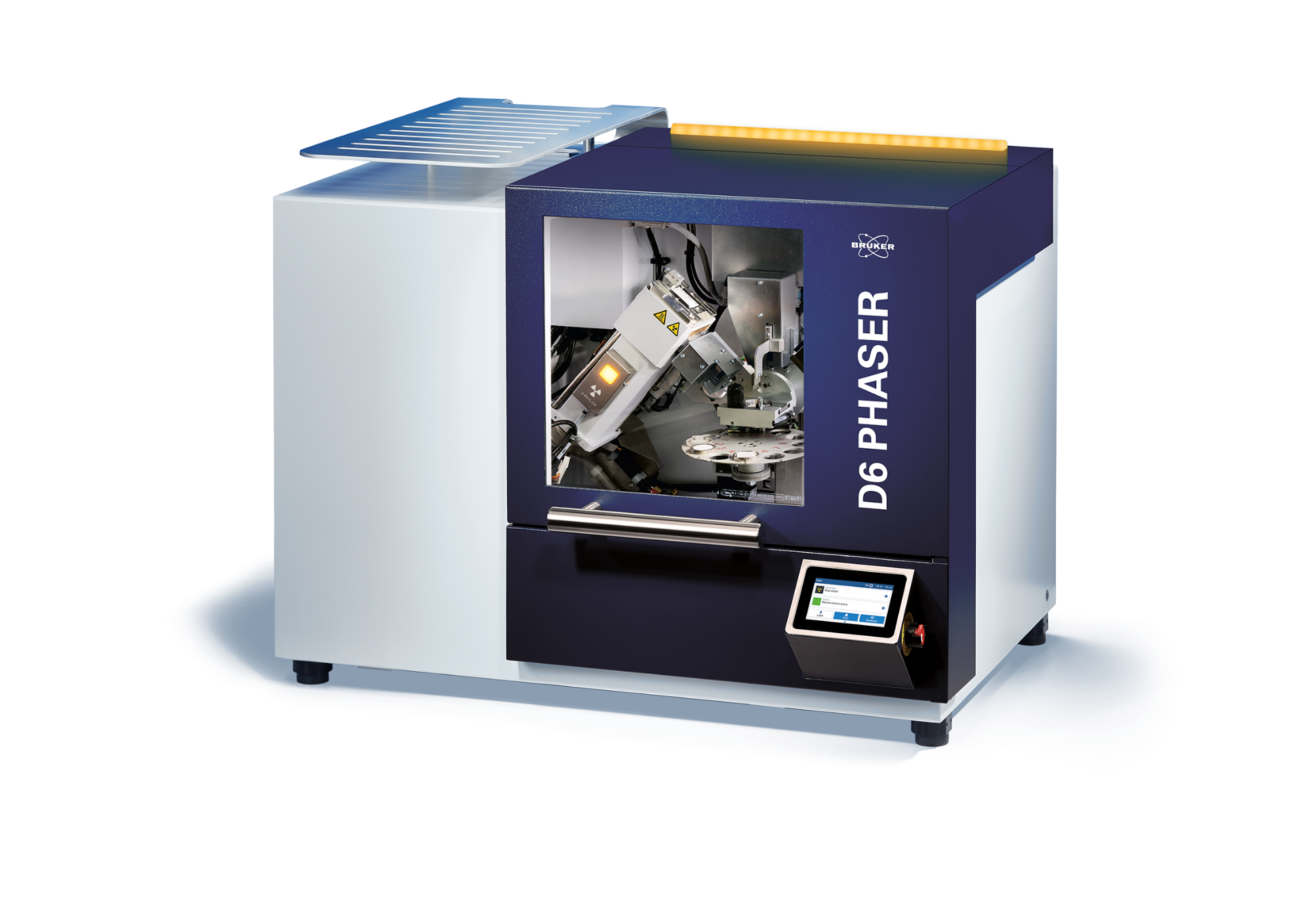

D6 PHASER

All-in-One Benchtop XRD

It’s all you need

A complete benchtop XRD analyzer platform

XRD has changed

D6 PHASER AUTOLOADER

X-ray Diffraction (XRD) plays a pivotal role in the process control of materials ranging from the cement used to build key infrastructure to the nanomaterials driving battery technology. Automation of this key technology is essential to obtaining consistent sample preparation, consistent system operation and consistent result determination.

D6 PHASER: XRD for Everyone, Everywhere and Everything

With the D6 PHASER benchtop XRD platform, the whole is greater than the sum of its parts. See how the D6 PHASER´s components combine to give you flexibility in analytical methods.

Applications of the D6 PHASER: Powerful. Versatile. Accessible.

Supporting a wide ramge of applications for powder, bulk and thin film analysis, the D6 PHASER platform is evergreen with the ability to incorporate new accessories to meet changing analytical needs and new scientific studies.

A new class of X-ray Diffractometers

“The D6 PHASER is the base of a new world of XRD solutions with compact size and unparalleled flexibility.”

Frank Burgaezy, President, Bruker AXS

For more than 60 years Bruker has created innovative analytical instruments to support the scientific community as well as users in industry. Our analytical solutions stand for cutting-edge technology and the highest performance. While we are providing top technology for scientists worldwide, over the past decades, we have more and more focused on making the latest analytical methods also accessible to a broader group of users.

At the forefront of this endeavor for accessibility are our benchtop instruments. Although they come with a smaller form factor than our landmark full-size systems, they share with them the same analytical instrument DNA, including the focus on data quality, robust hardware design, and reliable results.

The D6 PHASER is a groundbreaking benchtop XRD platform that combines operability and flexibility. Unlike traditional benchtop instruments, it offers advanced analytical methods beyond powder diffraction. With its wide range of applications, the D6 PHASER opens up new markets and user communities for XRD. Download the brochure to know more.

Powerful

The combination of the highest X-ray source-power on the market, small goniometer radius, the proven LYNXEYE detector family, and tailor-made beam optics outperform many floor-standing systems.

- Up to 1.2 kW with internal cooling

- Time-tested goniometer

- Energy Discrimination with LYNXEYE XE-T detector

- Optional motorized beam optics

Versatile

“The platform design of the D6 PHASER allows us to continually push benchtop XRD into new applications and markets.”

Michael Evans, Global Product Manager, D6 PHASER

One of the hallmark features of the D6 PHASER is the ability to adapt the system to a multitude of measurement types beyond basic powder diffraction, making it a truly universal platform for every experiment.

- Powder diffraction (reflection, capillary, foil transmission)

- Materials research (Stress, Texture)

- Thin film analysis (GID, XRR)

- Non-ambient and operando battery cell diffraction

- PDF analysis

Accessible

No training is required. The users are guided through analytical methods in an intuitive way based on our easy-to-use software and extensive knowledge of XRD analytical methods, while assisted by affordable, automated accessories.

- Dynamic Beam Optimization

- Touch panel operation

- Stage and optics exchange

Automated

Automated X-ray diffraction streamlines workflows, enhances safety, and maximizes efficiency. The D6 PHASER AUTOLOADER provides a state-of-the-art solution for analysis ranging from positive material identification to phase and structure quantification.

- Sample pre-loading

- Up to 5 magazine positions

- Stand-Alone or Online Operation

The AUTOLOADER allows external loading without having to open the instrument. In addition, sample rings can be automatically loaded and unloaded via an optional conveyor belt interface.

D6 PHASER Key Performance Metrics

Guaranteed Accuracy

Superior Resolution

Lowest, Smoothest Background

D6 PHASER Benefits

Traditional 2D XRD solutions utilize a very small spot on the sample with a very large detector. This works well for large instruments where space is available. In a benchtop, XRD 2D is used to assess the morphological state of the sample for insights into sample preparation and to associate reflections in phase ID. The D6 PHASER is capable of two forms of 2D diffraction. PHI 1D and the patented BRAGG2D utilize the full beam footprint in combination with any member of the LYNXEYE detector family to create a 2D diffraction image. This mode is available on every D6 PHASER no matter the detector, divergence slit, air scatter solution, or stage.

- No special requirements: compatible with any member of the LYNXYE Family of detectors

- High-intensity fast scans as the full-sized beam is used

- Large beam footprint gives a proper assessment of the overall sample preparation quality

- The same information that is available using traditional 2D detectors and small beam sizes

The D6 PHASER is the most powerful and versatile benchtop X-ray diffractometer on the market. The platform design of the D6 PHASER allows us to expand the benchtop concept with more tools and accessories for many years to come. As new technologies are discovered, the backbone systems in the D6 mean that we can create new attachments to extend the D6 PHASER.

- Reflection to transmission, flat plate to foils, bulk to films, standard conditions to non-ambient, a stage for every experiment

- Optimizing the beam is easier than ever before with a range of fixed and motorized slits, Sollers, and air scatter screens

Complete guidance and a friendly interface instill user confidence in component changes for optimal instrument utilization so that the instrument can be used to its fullest extent.

- Startup Verification: The instrument displays a yellow questioning face to indicate its unknown verification status upon startup.

- Touchscreen Interface: The instrument features a user-friendly touchscreen interface with a dedicated push button method to initiate the verification process.

- Evaluation Parameters: During verification, the instrument assesses peak position, relative intensity, and full width at half maximum of four peaks across the measurement range.

- Reporting and Icon Generation: The verification process generates a comprehensive report and an icon that visually represents the system's readiness.

- Readiness Indicators: A green smile icon indicates that the system is ready to use, while a red frown icon suggests the need for new reference values to be applied. Pressing the Referencing and Verification button facilitates this process, resulting in a green smile once the goniometer axis is confirmed to be within specifications.

When it comes to X-ray diffraction, the D6 PHASER AUTOLOADER provides a cutting-edge solution for analysis ranging from positive material identification to phase and structure quantification. Accessing these fast and reliable measurements is ideal for Big Data initiatives. The loading of the sample, the measurement, the unloading and the subsequent data evaluation can be fully automated, making the system operator-independent.

D6 PHASER Applications

XRD for Everyone

XRD is unique in its sensitivity to the fundamental form, not just the elemental identity of a material. As instruments like the D6 PHASER become available, wider adoption of the technique has been seen across markets and scientific disciplines. Obtaining reliable, high-quality XRD results no longer requires years of experience in the technique, allowing users to focus on their analytical area.

XRD for Everything

No matter the sample form, the D6 PHASER can be equipped to measure it. From transmission measurements between foils or in capillaries, to bulk or mounted metallurgical samples to thin films and coatings. Sample holders and stage accessories are both affordable and easy to install, lowering the barrier for adaptation to new sample types.

XRD for Everywhere

Benchtop solutions in the past were limited by their size. Power, versatility, and accessibility all limited the types of measurements that could be performed to classic powder diffraction or limited “advanced” functions. The D6 PHASER was designed to perform a wide variety of measurements while producing uncompromising results.

D6 PHASER Specifications

| Specification | Benefit | |

| Goniometer | Theta / Theta | Sample is always horizontal and cannot fall off during powder diffraction measurement |

| Angular accuracy | Alignment accuracy guaranteed within ±0.01° 2θ Traceable by included corundum (Cu, Co, Cr radiation) or Tungsten (Mo radiation) standard | |

| Generator | 40 kV 30 kV | 600 W or 1,200 W 540 W, optional, simplified registration for countries with 30 kV exception regulation |

| Cooling | Internal External | For all generator versions, no water supply needed Optionally available |

| Detectors | SSD160-2 LYNXEYE-2 LYNXEYE XE-T (*) Detector guarantee | Si-strip detector with 160 channels Ultra fast 1D detector (*) Ultra sensitive, energy dispersive 1D detector (*) absolutely faultless, no dead strips |

| Sample stages | Fix stage | For reflection and foil transmission without sample rotation |

| Rotating single or 12-position | Best sampling statistics, high throughput | |

| BTS 150/500 | Temperature chambers for powder diffraction | |

| Capillary stage | For transmission measurements, rotation for best sampling | |

| Universal stage | Omega/z movement with optional attachments for GID/XRR and Stress/Texture analysis | |

| AUTOLOADER | Automated external sample changer with up to 5 magazine positions, manual loading position, swing with preload function, and rotary sample stage for 51.5 mm or 40 mm diameter samples. One of the magazine positions can be exchanged for a belt connection for conveyor belts (up to 96 mm in width). | |

| Electrical specifications | 110 - 240 V AC, 200 – 240 V AC 47 - 63 Hz | Up to 600 W X-ray generator power For 1,200 W X-ray generator All domestic wall sockets supported |

| Operation | External PC Integrated touch panel | Windows 11, 64 bit Basis instrument operation, trouble shooting and push-button measurements and evaluations |

| Dimensions | H W D Weight | Small footprint, 70x88.5x67.7 cm (27.6″x35″x26.7″) Up to 160 kg (depending on configuration) |

| Safety | CE Compliance Radiation Safety | Machinery Directive 2006/42/EC, directive 2014/30/EU on electromagnetic compatibility Directive 2013/59/EURATOM, safety circuit to meet EN ISO 13849-1:2015 |

Plan. Measure. Analyze with the DIFFRAC.SUITE software

Our X-ray diffraction software solutions are centered around the Plan. Measure. Analyze. concept, providing users with a seamless and intuitive experience. We leverage our extensive knowledge of XRD analytical methods to guide users through the analytical process.

The full-featured, and no-compromise DIFFRAC.SUITE software package provides the easiest measurement method creation and the most powerful and accurate analysis results.

The DIFFRAC.SUITE MEASUREMENT CENTER, DIFFRAC.EVA for general data evaluation and the COD database for phase identification are always included with two licenses for industrial labs and 10 licenses for academic users.

Users start by configuring the appropriate components for their measurements using DaVinci, a graphical representation of the instrument. Our software offers clear instructions and guidance for configuring the instrument setup.

The WIZARD tool allows users to plan method files for measurements. It provides step-by-step guidance through interactive templates, enabling users to define various measurements, including advanced features like variable step size, variable counting time (VCT), non-ambient temperature profiles, texture, stress, grazing incidence diffraction, and X-ray reflectometry.

COMMANDER offers multiple ways to execute measurements on the D6 PHASER. The immediate measurement interface provides direct control over the instrument, including generator power, configured axes, and scan conditions. The interface dynamically adjusts based on the chosen components in DaVinci. Alternatively, the JOB interface allows users to launch measurements using method files generated by WIZARD. A push-button interface is also available for executing method files with a single click or touchscreen interaction.

Measurements are stored in the result database and can be saved as files to specific locations. Our software provides automated analysis routines and a comprehensive scripting platform, allowing users to launch analyses and store the results directly in the database.

DIFFRAC.SUITE, along with the analysis applications, offers controlled access through a user database. This ensures that the right people have access to the appropriate features. The software is also GxP compatible, complying with the 21 CFR Part 11 protocol for regulated industries.

D6 PHASER Resources

Brochures, Spec Sheets, and Application Reports

- D6 PHASER – Benchtop Non-ambient XRD

- D6 PHASER – Benchtop XRD for the Analysis of Crystallite Sizes

- D6 PHASER – Benchtop XRD for Nanoscale Sieve Characterization

- D6 PHASER – Benchtop XRD Residual Stress Analysis

- D6 PHASER – Benchtop XRD Texture Analysis

- D6 PHASER – Benchtop XRD for Monitoring Silica Dust Exposure

- D6 PHASER – Benchtop XRD Two-Dimensional Diffractometry

- D6 PHASER – Benchtop XRD Total Scattering Analysis (PDF)

- D6 PHASER – Benchtop XRD X-ray Reflectometry (XRR)

- D6 PHASER – Benchtop XRD Grazing Incidence Diffraction (GID)

- D6 PHASER 600W – Cement Phase Quantification

- D6 PHASER 1.2kW – Cement Phase Quantification

- D6 PHASER – Operando XRD on a Benchtop

Service & Support

- Helpdesk for technical issues with hardware, software, and applications support using web based and advanced remote service tools.

- LabScape Maintenance Service Agreements

- On-site, on-demand support

- Installation and operational qualification as well as performance verification

- Site planning, relocation, and consultation

- Replacement and spare parts, consumables, and in-person and online training

- Software updates, manuals, and LabScape MSA management (↗brukersupport.com)