In-situ Nanoindenting Optimized for Mechanical Characterization of Soft Biomaterials

Advanced nanoindentation for soft biomaterials

Nanoindentation is a powerful tool for characterizing many types of materials. However, it can be challenging to perform nanoindentation on soft materials, such as biological samples or hydrogels, due to their low modulus, heterogeneity, and environmental requirements during testing. Bruker’s Hysitron BioSoft™ in-situ indenter is specifically designed for multiscale quantitative mechanical testing of biological materials and soft matter, such as hydrogels. This application note discusses the utilities and advantages of using the BioSoft in-situ indenter for the characterization of soft materials. Two case studies highlighting the applications and unique capabilities of this tool for characterizing hydrogels and biological tissues are also provided.

About the Hysitron BioSoft Nanoindenter

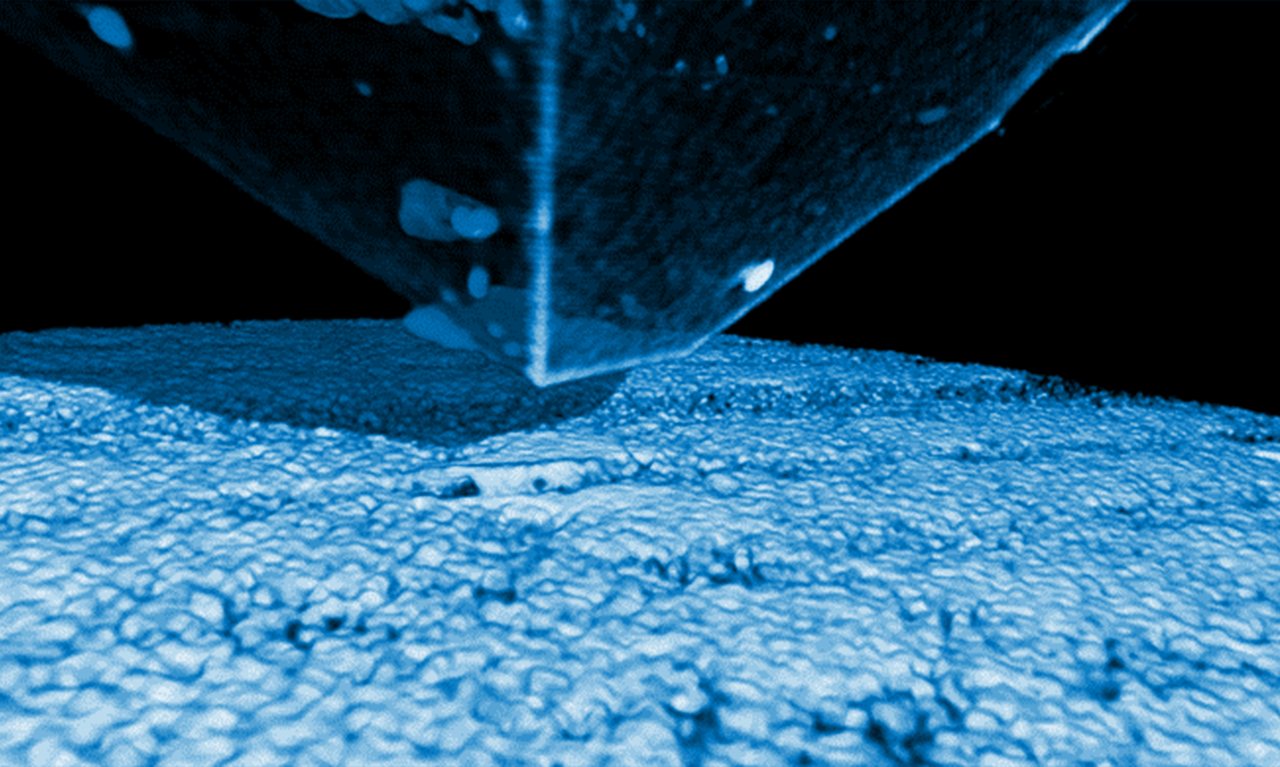

The Hysitron BioSoft is optimized for quantifying the mechanics of the biological world. It combines powerful mechanical and optical characterization techniques to achieve a comprehensive understanding of the mechanics of soft materials. With advanced targeting and precision, the instrument provides a unique combination of force sensitivity and displacement range specifically engineered to measure soft biological specimens from sub-cellular to tissue levels. The system performs advanced indentation that is optimal for delicate, soft materials to enable non-destructive multiscale characterization of localized and bulk properties.

Pairable with Inverted Microscopes

The first-of-its-kind BioSoft seamlessly attaches to an inverted microscope, allowing researchers to visualize the area of interest before performing indentation. This enables users to know exactly where they are within a sample, which is especially important for measuring specific portions of biomaterials that have heterogeneity across the sample.

Customizable Measurement Tips for Soft Materials

Unlike other nanoindenters that use a cantilever for measurements, BioSoft uniquely utilizes a piezo-driven flexure with a capacitive load cell. Using a piezo allows for more idealized measurements by providing near-perfect linear actuation and limited shear compared to what is achievable with a cantilever. The tips on the piezo are interchangeable so that users can change the contact geometry, which is also important for soft materials with heterogeneity of modulus across the sample.

Designed for Testing in Fluid with Environmental Control

BioSoft supports testing of samples in controlled environments, and most importantly, has the ability to test in fluids. This is critical for biomaterials as they typically need to be hydrated to remain alive. Additionally, testing in a fluid environment is important for hydrogels, as their structural integrity will be compromised if they do not remain hydrated.

Measurement Capacities Optimized for Soft Materials

For soft (<1 MPa) and supersoft (<100 kPa) materials, the ability to accurately measure the contact stiffness requires a large throw, while minimizing noise and maximizing the measurement linearity. BioSoft provides access to physiological pressures from Pa to kPa. The instrument maintains a 750 nN noise floor and a <1 nm displacement noise floor and delivers up to 10 mN force and 150 μM displacement range. The complementary Advanced BioMech Control Module allows researchers to change between load control (stress) and displacement control (strain) during a given test.

Easy-to-Use Software

Bruker’s BioScan™ software package provides an intuitive graphical user interface to streamline the testing process, while providing the flexibility to accommodate a broad range of testing needs.

Case Study #1: Characterization of the Mechanical Properties of Contact Lenses

In this experiment, the BioSoft in-Situ indenter was successfully used to measure mechanical properties of two distinct types of contact lenses.1 The mechanical properties of a contact lens, such as stiffness, affect important characteristics, including comfort, ease of handling, and even optical properties. Low-modulus contact lenses are difficult to handle and provide insufficient movement during blinking, leading to poor tear exchange. High-modulus contact lenses can result in mechanically induced eye health complications, such as superior epithelial arcuate lesions, contact lens–induced papillary conjunctivitis, and mucin ball formation. Water content, hydraulic permeability, and viscoelastic behavior inherent to the hydrogel all factor into the mechanical response of a lens. Depth-sensing indentation offers a non-destructive, rapid, reliable, and quantitative method for characterizing the modulus of materials.

BioSoft was used to measure the mechanical response of three contact lenses made of different materials, two types of 2-hydroxyethyl methacrylate (HEMA)-based and one silicone-based hydrogel (SiHy). The result was that HEMA and SiHy lenses showed significant differences in measured effective modulus as a function of loading rate, displacement into the contact lens surface, and relaxation time (Figure 1). This finding has critical implications in the development and optimization of contact lens materials.

Case Study #2: Characterization of Elastic

Properties of Cartilage Tissue

In another experiment, the BioSoft nanoindenter was used to characterize localized mechanical properties across a sample of articular cartilage.2 Articular cartilage is a specialized connective tissue suited for the distribution of contact loads within diarthordial joints. It is a biphasic material that exhibits anisotropic and nonlinear elastic behavior. The liquid phase, primarily water, makes up 65% to 80% of the cartilage by weight. The solid phase consists of dispersed proteoglycans within an extracellular matrix of collagen and glycoproteins. The structure contains four zones based on the arrangement of the collagen fibril network, as shown in Figure 2. Mechanical properties vary across the four zones, meaning that high spatial resolution is needed for characterization of the localized regions of the tissue.

BioSoft was successfully used to probe local mechanical properties across the sample. After collecting modulus measurements from the four zones, the modulus was observed to decrease from the deep zone to the STZ (Figure 3). This makes sense, as the fluid content, which inversely correlates with modulus, increases near the STZ. The modulus approaches that measured on the articular surface, but plateaus at a slightly higher value. This anisotropy is likely due to preferential alignment of the collagen fibrils parallel to the articular surface. The greater deviation observed near the deep zone may be attributed to an increased disparity of the material structure between indent locations.

Summary

Bruker’s Hysitron BioSoft In-Situ Indenter is a first-of-its-kind instrument specifically designed for multiscale quantitative mechanical testing of biological materials and soft matter that opens doors to various applications in the life sciences. BioSoft synchronizes powerful mechanical and optical characterization techniques to achieve a comprehensive understanding of the mechanics of biomaterials. Bruker has developed a comprehensive suite of nanomechanical and nanotribological test instruments that operate in conjunction with powerful microscopy techniques.

References

- Bruker Application Note #1508: Indentation of Contact Lenses Using the Hysitron BioSoft In-Situ Indenter (2017).

- Bruker Application Note #1500 Characterization of the Elastic Properties of Cartilage Tissue by Indentation (2017).

Authors

- Savana Lipps, Life Science Writer, Bruker Savana.Lipps@bruker.com

- Douglas Stauffer, Sr. Manager of NI Applications Development, Bruker, Douglas.Stauffer@bruker.com

Acknowledgements

This application note is sourced from material originally written by:

Prof. Melih Erten

University of Wisconsin-Madison

Ben J. Stadnick

Bruker

Praveena Manimunda, Ph.D.

Bruker

BioScan, BioSoft, and Hysitron are a trademarks of Bruker Corporation. All other trademarks are the property of their respective companies. © 2021 Bruker Corporation. All rights reserved. AN1545, Rev. A0