iTF - Intrinsic Thin Film Mechanical Property Solution

Film Thickness Independent Modulus Characterization

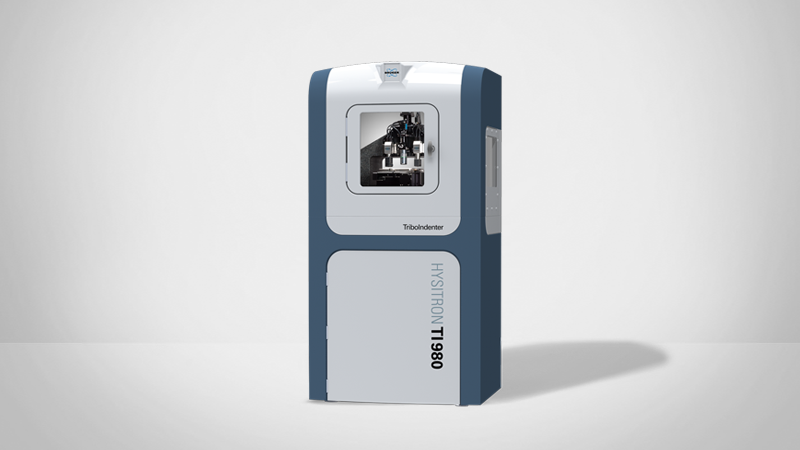

iTF is Bruker’s new analytical software package that provides the most versatile solution to thin film systems. From hard on soft to soft on hard, from 2nm to 2mm, iTF generates accurate intrinsic thin film modulus within minutes. iTF is based on a patented elastic-plastic contact model developed by a research group from Harvard University and optimized for the wide range of Hysitron’s nanomechanical instruments. Since commercialization, iTF has been widely used in microelectronic, automobile, aerospace, and coating industries.

Accurately Account for the Substrate Effect

Traditional nanoindentation analysis utilizes the initial unloading segment to represent a pure elastic response. However, when the instrument probes onto a thin film system, the elastic response is a the material’s response comprised of that much deeper than the actual contact. Using the traditional nanoindentation analysis will result in a deviation from the thin film mechanical response. This substrate effect makes it difficult to understand the film’s own mechanical properties using nanoindentation. iTF calls for pressure distribution with layer material structure in mind, and numerically calculates the intrinsic film modulus. Thus no more substrate effect in nanoindentation analysis, no matter how deep you go.

Simple Operation

Simply put the sample in, 300mm wafer or 3mm chip, perform a depth profile indentation, query the iTF software, and thin film modulus is readily available. iTF software recognizes all file formats from Hysitron nanoindenter, and capable of automating multiple sample analysis. Simple slider bar allows high speed or high accuracy analysis.

Classic Contact Mechanics Model Core

iTF’s core is the classic contact mechanics based on layered materials contact solutions. By reconstructing pressure distribution and boundary conditions with a variety of indent geometries, stiffness, indentation load and displacement become the fingerprint of each thin film system. Matching nanoindentation data with the large library of indentation behaviors of thin films in iTF software, intrinsic thin film modulus is easily pinpointed. The use of classical contact mechanics also enables the large range of elastic mismatch between the film and the substrate.