Quality by Design

The drug development, manufacture and quality control paradigm has shifted dramatically in recent years. Regulators are increasingly driving pharmaceutical and biopharmaceutical companies to demonstrate more complete knowledge of the mechanism of action, metabolism and toxicity early in development. This approach is extended to downstream processes too. Product development, product characterization as well as API manufacture and secondary manufacture all now operate under Quality by Design (QbD) principles.

Bruker technologies and instruments are applied to meet the goals of improved process understanding and closer control of manufacture.

Empirical analysis of test batches is replaced with a set of key product and process considerations – Critical Quality Attributes (CQA) and Critical Process Parameters (CPP) – that are scientifically designed to meet the desired final-quality objectives and meet the US FDA Pharmaceutical Quality Assessment System (PQAS).

In practice, these critical attributes are worked into a design space model for the product and process so that clear control and monitoring regimes can be established. For pharma and biopharma manufacturing, the result is lower risk of rejected batches and rework, higher assurance of product quality, and the creation of a manufacturing environment where continuous improvement can flourish.

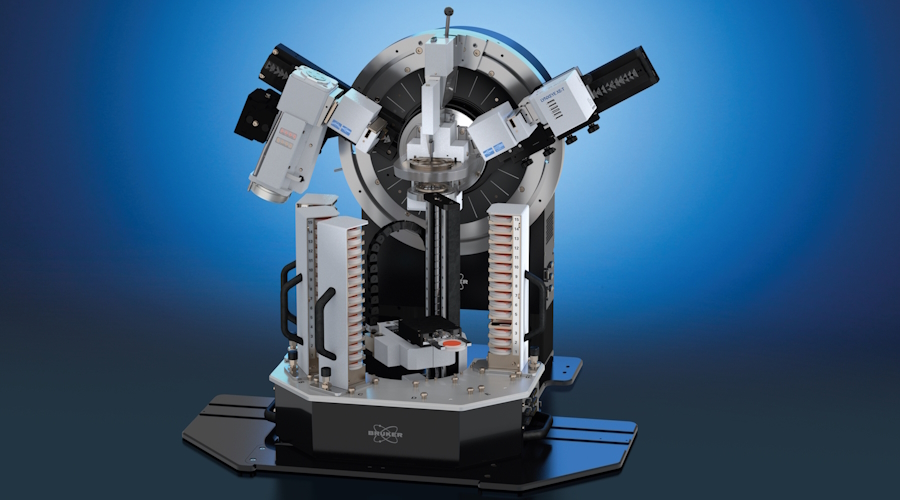

In order to meet the demands of QbD, scientists rely on more powerful analytical instruments to provide the information, insight and control they need. Bruker’s core NMR and optical spectroscopy technologies are employed throughout - from method development to in-situ / on-line analysis in the process.

NMR and FT-IR / FT-NIR have emerged as essential tools for QbD. The quantitative nature and unparalleled structural information given by NMR is being applied to reaction elucidation and the screening of reaction conditions as well as further downstream to monitor reactions on-line.

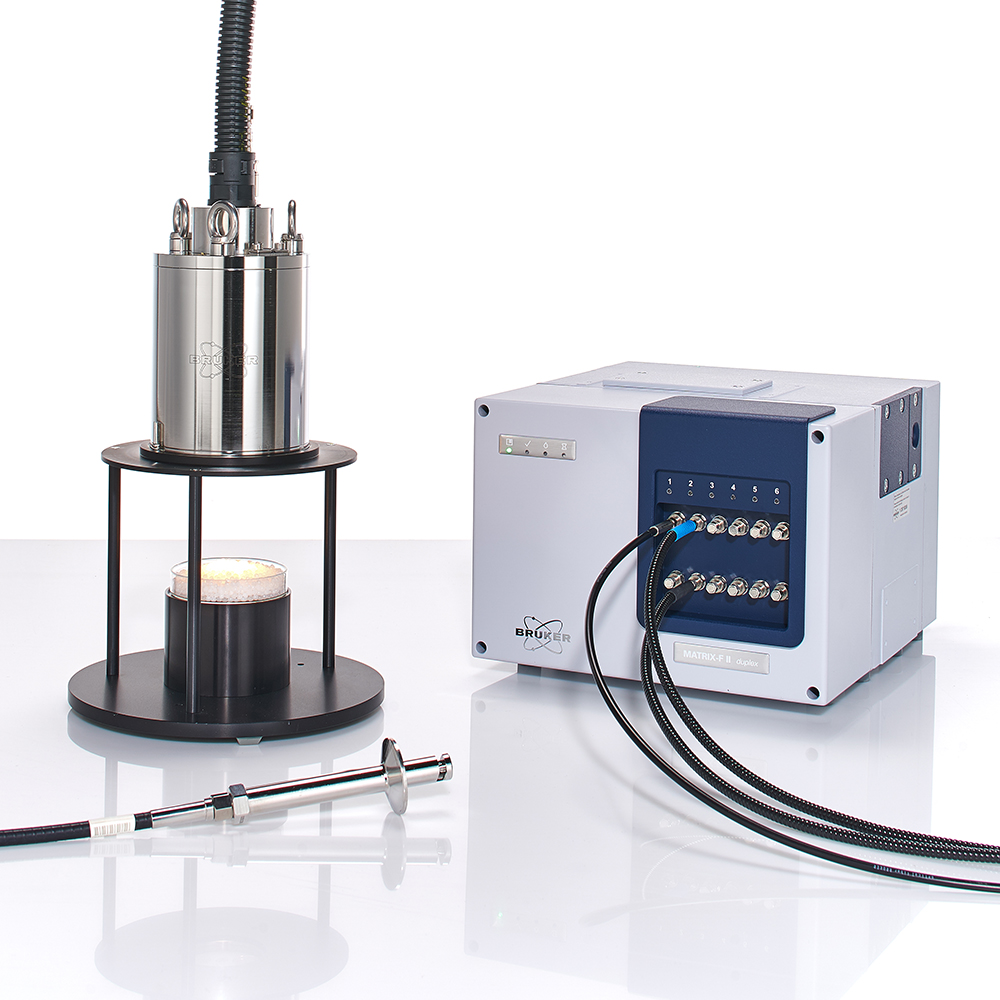

Optical spectroscopy is today a very important method for on-line process monitoring and optimization. FT-IR/NIR instruments measure the unique infrared ‘fingerprint’ of every chemical to identify and quantify them in the manufacturing process. Fiber-coupled probes now allow a direct look into the process in real-time.

Bruker’s range of instruments provide the features and performance required to be easily incorporated into the establishment and subsequent daily routine of a QbD approach.

LabScape

Service & Life Cycle Support for Magnetic Resonance and Preclinical Imaging

Bruker’s commitment to provide customers with unparalleled help throughout the buying cycle, from initial inquiry to evaluation, installation, and the lifetime of the instrument is now characterized by the LabScape service concept.

LabScape Maintenance Agreements, On-Site On-Demand and Enhance Your Lab are designed to offer a new approach to maintenance and service for the modern laboratory