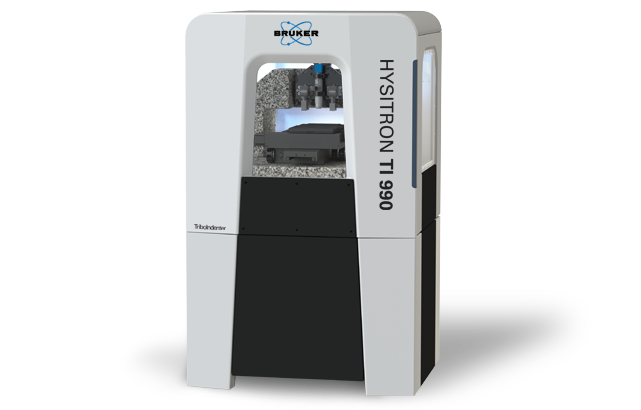

Hysitron TI 990 TriboIndenter

Hysitron TI 990 TriboIndenter

The Hysitron TI 990 TriboIndenter achieves remarkable advances in control and throughput capabilities, testing flexibility, applicability, measurement reliability, and system modularity — enabling more and better research than previously possible.

Bruker's next-generation Hysitron TI 990 TriboIndenter® sets new standards for performance, flexibility, and usability in nanomechanical and nanotribological characterization. A comprehensive advancement of Bruker’s industry-leading TriboIndenter platform, every aspect of TI 990's measurement and analysis process features updated technologies designed to remove the normal limitations of nanoindenter systems. As such, this system features the most measurement modes available and delivers high-precision measurements in the broadest range of laboratory environments.

Powerful Base Configuration

- Dual piezo scanners for in-situ SPM imaging

- High-resolution, color optics

- Exclusive low-noise 2D capacitive transducer

- Metrology-grade granite framing for test stability

- Integrated active anti-vibration system

- Performech III controller

- Vibration-dampening base with 50x improved noise immunity

- Multi-layered environmental isolation enclosure

- Top-view sample-chuck imaging

- Property mapping with XPM II ultrahigh-speed nanoindentation

- Dynamic nanoindentation

- Modular enclosure with customizable panels

- Universal sample chuck

- High-precision, motorized/automated stage with 60% more testable area

No System Has More Testing Modes

With its enhanced measurement capabilities, increased sample flexibility, easier system setup, and more streamlined operation, TI 990 is an unrivalled characterization solution for a variety of applications.

Whether you need improved accuracy for polymer thin films, increased throughput for combinatorial materials science, or multi-measurement analysis of full 300-mm semiconductor wafers, TI 990 keeps up with your dynamic testing needs.

Contact us to discuss your specific application, process needs, and measurement requirements.

Expand TI 990's Capabilities

LEARN MORE:

Contact us for more information about available upgrade options and how TI 990 can be configured to meet your specific measurement needs now and grow with your research going forward.