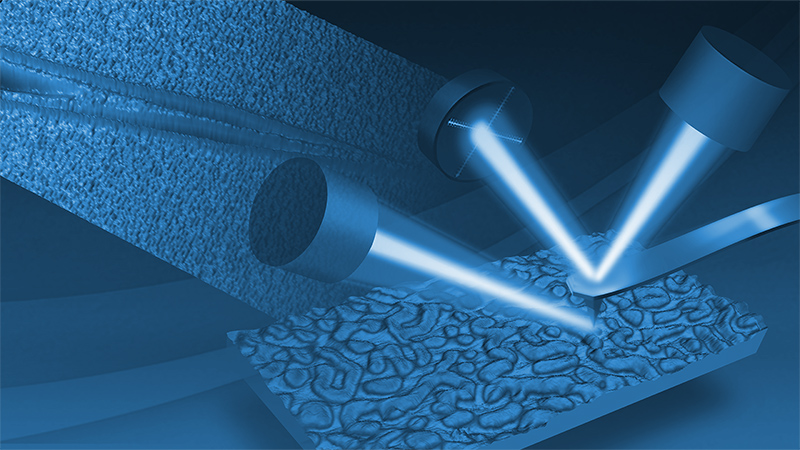

nanoIR Journal Club

Top articles using Bruker's photothermal AFM-IR technology delivered direct to your inbox.

Our Journal Club is meant to be a helpful tool that keeps you up-to-date on the newest in nanoscale infrared spectroscopy research and to assist you in discovering articles you may have missed.

Members of our nanoIR Journal Club receive brief reviews of select papers and direct links to the full article.

OTHER ARTICLES RECENTLY REVIEWED INCLUDE:

- Applications of AFM-IR for Drug Delivery Vector Characterization: Infrared, Thermal, and Mechanical Characterization at the Nanoscale by Jing Zhang et.al. | DOI: 10.1016/j.addr.2022.114646

- AFM-IR and IR-SNOM for the Characterization of Small Molecule Organic Semiconductors by Vaishnavi Rao et.al. | DOI: 10.1021/acs.jpcc.9b11056

- Sustainable Immiscible Polylactic Acid (PLA) and Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHBV) Blends: Crystallization and Foaming Behavior by Christian Brütting et.al | DOI: 10.1021/acssuschemeng.3c00199

... and many more.