QUANTAX Micro-XRF

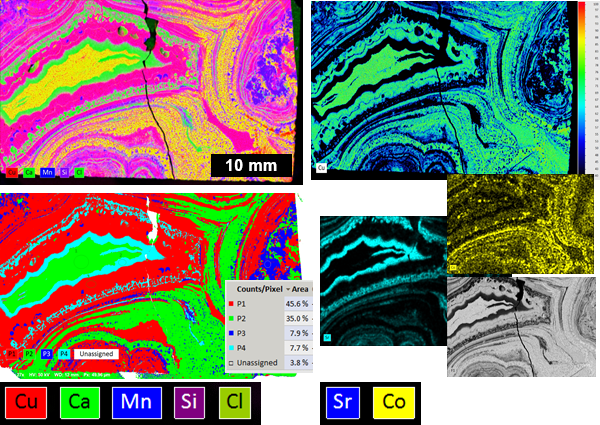

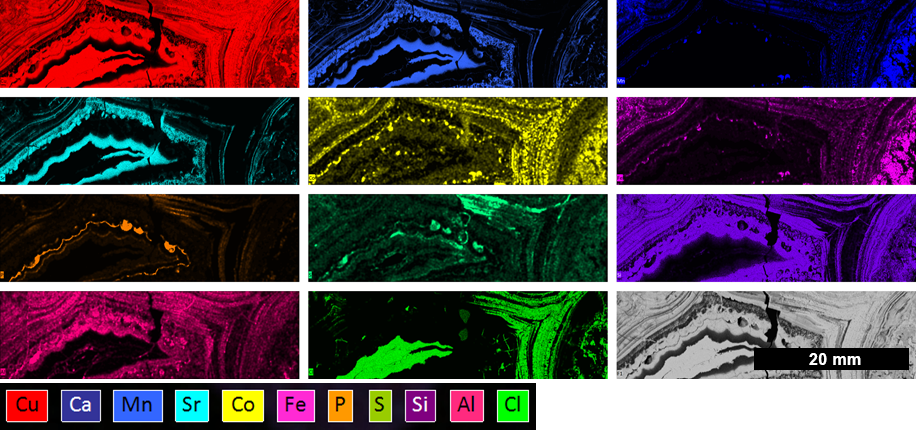

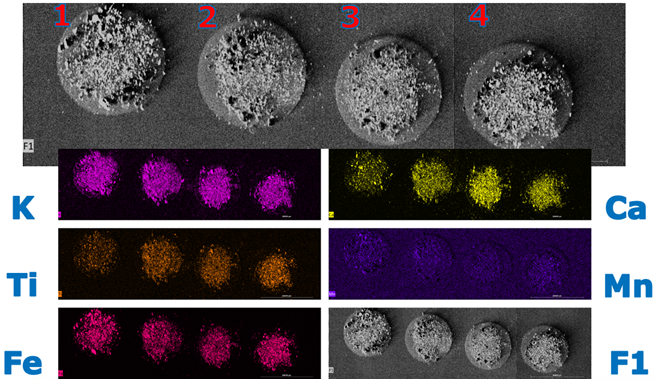

High-Speed Elemental X-ray Mapping even over Large Areas

Film Thickness Analysis

Expand your SEM Capabilities - Augment SEM EDS with micro-XRF Analysis

Micro-X-ray Fluorescence (micro- XRF) spectroscopy is a non-destructive analytical technique that can be used alongside conventional Energy Dispersive Spectroscopy (EDS) on a Scanning Electron Microscope (SEM).

Micro-XRF on SEM, also known as SEM XRF, delivers the SEM with a range of new capabilities such as the ability to measure and map trace elements, the analysis of layered samples, and more.

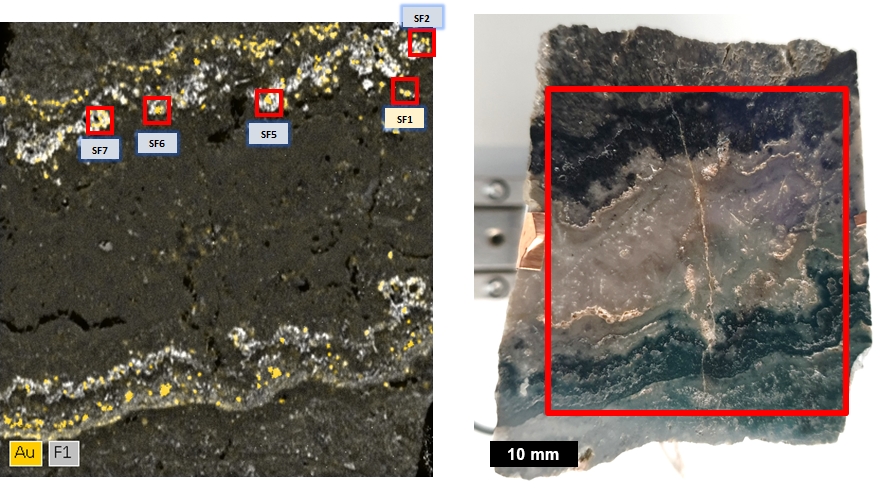

Trace Element Detection

X-ray analysis is more sensitive towards trace elements, allowing their detection at concentrations down to as low as 10 ppm for certain elements, an extended X-ray spectral range (up to 40 keV), as well as information from a greater depth within the sample.

Elemental Mapping with Small Spot Sizes

QUANTAX micro-XRF is equipped with XTrace 2, our latest X-ray source, including a micro-focusing X-ray optic that yields small spot sizes of down to 10 µm at a high-intensity throughput.

Multilayer Sample Analysis

The larger depth of X-ray excitation allows for the characterization of multilayer samples from 1 nm up to 40 µm, which is not possible via electron beam excitation.

The Combined Power of Electron Beam and X-Ray Analysis

- Achieve a more comprehensive analysis - Augmenting SEM EDS with micro-XRF provides users with dual beam potential, allowing samples to be even simultaneously analyzed using an electron beam and an X-ray beam.

- See more elemental lines - High energy K- line detection allows to positively identify typical SEM-EDS overlap.

- One measurement for two spectra - EDS and micro-XRF acquisition take place in the same detector, incorporating light element spectral data as well as trace elements with higher energy X-ray data.

- Collect cleaner data - Well-separated peaks and an extended spectral range enable the seperation of high energy K- lines since they are less complex and less overlapped.

- Save time - no or minimum sample preparation required without the need for a conductive sample surface and/or extensive polishing.

What is included in the QUANTAX Micro-XRF System?

QUANTAX Micro-XRF provides the tools a user needs to conduct micro-XRF analysis within their scanning electron microscope. The system consists of:

- An XTrace 2 50 kV X-ray source

- ESPRIT software for data processing and analysis

- An XFlash® EDS detector for high-intensity throughput analysis with extended energy range (existing on SEM or purchased seperately)

- Rapid Stage for high-speed elemental mapping (optional)

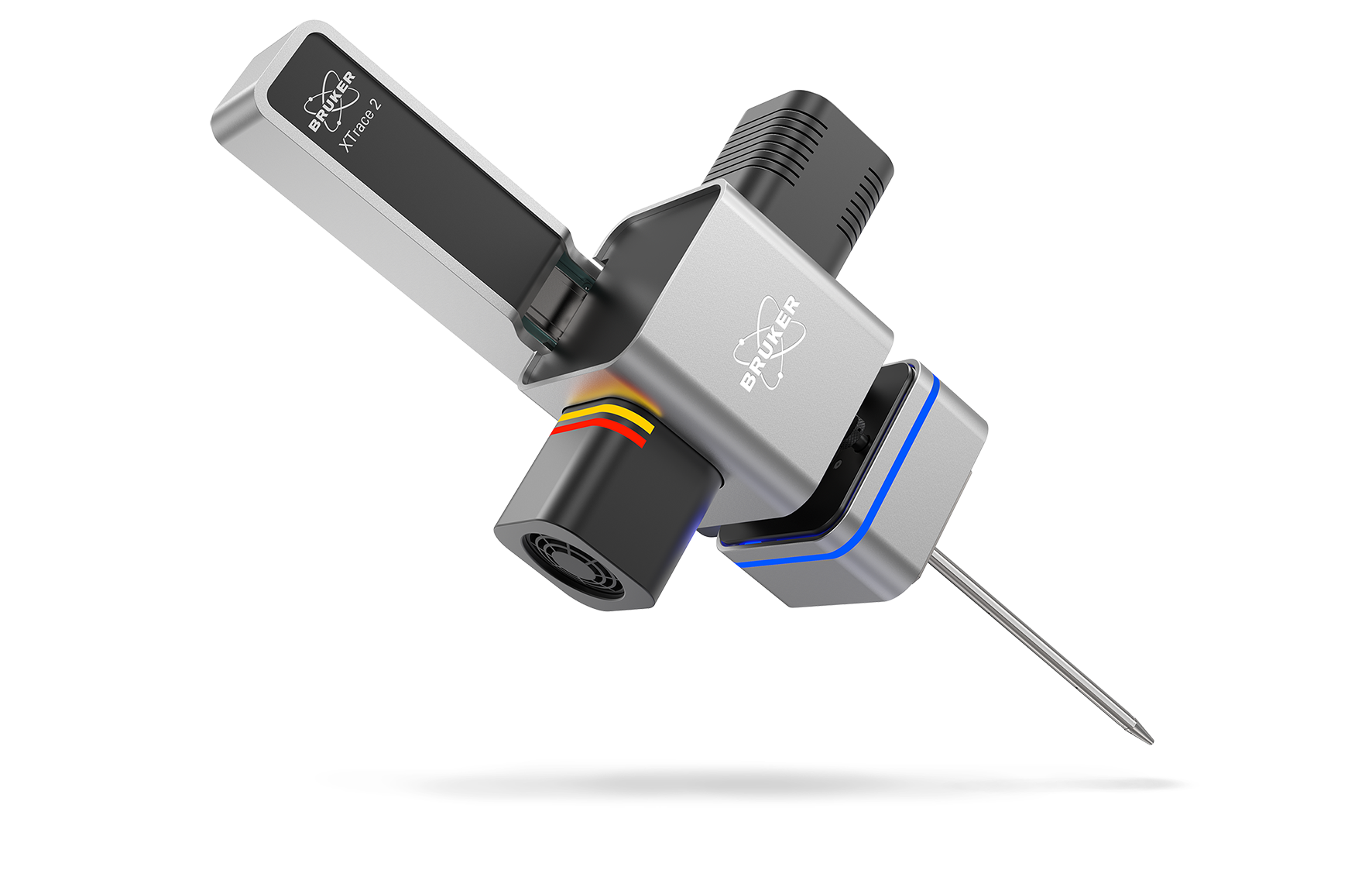

XTrace 2 - Advanced X-Ray Source for micro-XRF on SEM

XTrace 2 is the next-generation X-ray source in the QUANTAX micro-XRF system for micro-XRF on SEM (SEM XRF). This new and innovative X-ray source enables fast micro-XRF spectral acquisition with high-resolution data.

Advanced features, such as a FlexiSpot mode, an Aperture Management System, and motorized filter selection facilitate the collection of rich data from even challenging samples.

- Collect accurate elemental data quickly and efficiently with high-energy X-rays of 50 kV and beam currents of 1000 µA for a high count rate.

- Detection of trace elements at low ppm levels with automatic switching between 6 primary filters for enhanced background reduction.

- Scan topographic samples in high resolution using an Aperture Management System (AMS) that keeps the image in focus across a variable working distance.

- Analyze inhomogeneous and/or irregular samples using FlexiSpot mode, allowing spectral measurements from a small to a larger spot size.

- Retract the X-ray optic when not needed by using a motorized linear stage with automatic source retraction (measuring and parking position).

- Return to areas of interest on your sample by saving measurement positions for correlating micro-XRF / e-beam analysis.

- Maximize X-ray tube lifetime with by automatic X-ray tube warm-up procedure.

- Control the analysis, select filters, and move the linear stage using the intuitive ESPRIT software.

Aperture Management System (AMS) for the Analysis of Topographic Samples in the SEM

XTrace 2 is equipped with the patent protected AMS to retain X-ray spot resolution even when scanning samples with a complex topography in the scanning electron microscope.

The AMS in XTrace 2 keeps the optic in focus at varying working distances by increasing the depth of field. This means that any reduction in resolution due to deviations in the working distance will be minimized, facilitating the high-resolution elemental mapping of highly topographical samples and their 3D features.

FlexiSpot - Variable Spot Sizes

FlexiSpot allows users to not only take measurements from small spot sizes (10 μm, 35 μm) but also a range of larger spot sizes (50 - 500 μm). FlexiSpot works by retracting the X-ray source, allowing the X-ray optic to be defocused out of the nominal optic working distance. Users can select between spot sizes using the automated process in our ESPRIT software.

The ability to measure larger spot sizes allows for a more precise quantification of non-homogeneous and irregular shaped samples, as well as samples with uneven surfaces, such as powders. A large spot area provides more statistically accurate data on a sample's composition in just one measurement.

Easy Switching between up to 6 Primary Filters for Further Background Reduction

The new XTrace 2 comes with 6 primary filters allows the user to adapt the background over the whole energy range up to 40 keV for further improved sensitivity.

Additional filtering allows for the reduction of the background for specific measurements at energies up to 40 keV. Primary filters can be selected via our ESPRIT software.

Auto Source Insertion & Retraction Mode

The polycapillary optic of the X-ray source can be automatically inserted and retracted using XTrace 2's motorized linear stage.

Advanced Safety Interlock

The status (open/close) of the SEM load lock chamber can be integrated in the XTrace 2 security circuit - this safety feature ensures that the X-ray shutter cannot be opened when the load lock chamber is open, keeping users safe from X-ray exposure. The advanced safety interlock is designed to work with various SEM models.

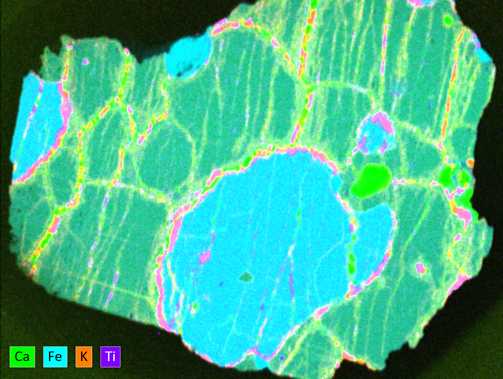

Correlating micro-XRF with e-Beam Analysis

XTrace 2 is a micro-focus X-ray source that can be directly integrated on any type of SEM.

Micro-XRF on SEM analysis and Energy Dispersive X-ray Spectroscopy (EDS) can be used independently or in a correlative workflow, enabling large-area mapping with high spatial resolution as well as the analysis of both surface and sub-surface layers. Using marked stage positions in the ESPRIT software, regions of interest can be automatically tagged for remeasurement without removing the sample, ensuring seamless navigation.

The combination of micro-XRF on SEM with SEM EDS capitalizes on the strengths of both analytical techniques, allowing for more-efficient and comprehensive material characterization. This innovative solution combines rapid large-area analysis with high-spatial-resolution elemental analysis in the SEM.

Rapid Stage - Fast Elemental Mapping over Large Sample Areas

Rapid Stage is a modular piezo-based stage, specially designed to mount on top of the existing SEM stage, enabling high-speed elemental X-ray mapping “on the fly” over large areas with up to a speed of 10 mm/s.

The use of Rapid Stage allows for the acquisition of X-ray mapping data over a sample size of 50 x 50 mm (or higher), incorporating light element spectral data as well as trace element and/ or higher energy X-ray data in a fast and user-friendly workflow.

Both XTrace 2 and Rapid Stage are seamlessly integrated in ESPRIT software.

Further Fields of Application for micro-XRF on SEM

Resources & Publications

Learn about Full Range EDS - Combining EDS with micro-XRF on SEM

Interested in learning about the combination of energy dispersive spectroscopy (EDS) with micro-XRF on SEM? Visit our explainer page:

Product Videos

Application Notes

- MXRF 01 - Analysis of mineral wool

- MXRF 02 - Comparison of element detection with EDS and micro-XRF on SEM

- MXRF 03 - Analysis of a certified copper alloy

- MXRF 04 - Analysis of metal traces in polymers

- MXRF 05 - Analysis of Mo in alloy steels

- Combined SEM Techniques 01 - Quantification of steel and alloys

Publications

- 2022 - Major to trace element imaging and analysis of iron age glasses using stage scanning in the analytical dual beam microscope (tandem)

- 2021 - Science Direct: A dual beam SEM-based EDS and micro-XRF method for the analysis of large-scale Mesoamerican obsidian tablets

- 2017 - Micro-XRF in Scanning Electron Microscopes