Pet Food

Analysis of Pet Food

When it comes to pet food, consumers expect top quality for their loved ones. Pet food regulations require 'guaranteed analysis' information on the label. Moreover, the products must be safe and free of any harmful substance.

Bruker offers solutions based on FT-NIR spectroscopy for a fast and reliable quality control of incoming pet food ingredients as well as the finished pet food. Samples can be analyzed non-destructively in seconds for the main constituents like moisture, fat. Protein, fiber, and ash, saving costs by reducing time and reagent use.

Analyzing in the lab or at-line close to production requires just filling an easy-to-clean cup with the solid sample and to present it to the analyzer. Bruker Optics comprehensive calibration packages for feed and ingredients are developed following the ISO 12099 guideline.

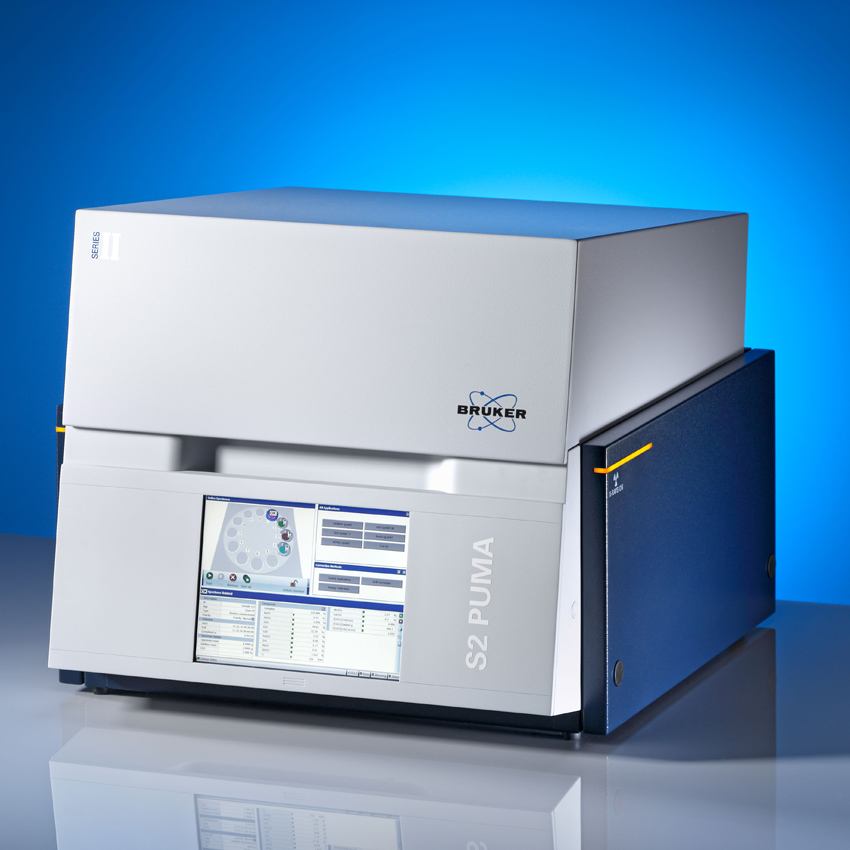

X-ray fluorescence (XRF) enables fast and nondestructive analysis of macro-, micro- and trace mineral nutrients from starting materials to final pet food products. Equally important is its ability to screen for toxic metals and to monitor additives such as Na and fortificants such as Fe. Bruker’s Elemental Analyzer portfolio includes high-throughput lab-based ED-XRF and WD-XRF, point-and-shoot handheld XRF, micro-XRF, and ultra-trace analysis TXRF spectrometers.

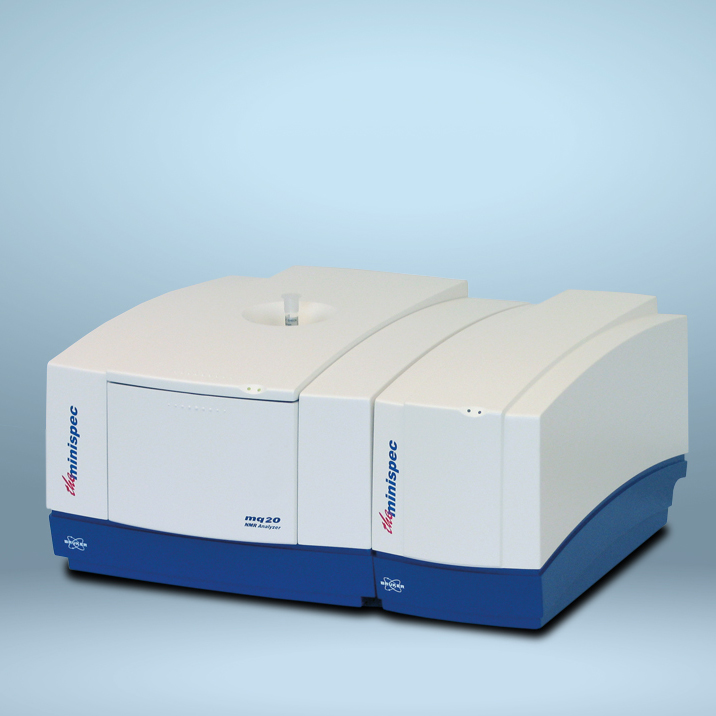

The total fat content of pet food can be easily and rapidly determined using the bench-top TD-NMR analyzer. The measurement takes typically less than one minute and is the method of choice for Quality Control (QC) in the food industry with minimal sample preparation and high accuracy (e.g.+-0.1% for total fat determination).

Any foreign objects found in pet food must be identified to determine their origin for taking corrective action. XRF and FT-IR can rapidly identify such tiny pieces of physical contaminants in the factory or in the laboratory. While XRF spectroscopy is ideal for metals, ceramics, stone and glass, the complementing FT-IR technology is most effective for plastics, rubber, and other organic compounds.

Fish feed pellets are pretty complex to make with different production steps such as extrusion and vacuum coating involved.

Despite the fluctuating quality of the raw materials used, the final product needs to be of constant quality both in terms of nutritional as well as physical properties.

A key parameter to control is therefore the pellet microstructure because it has a significant impact e.g. on the fat distribution, the floating behavior in the water, or the mechanical strength during transport.

XRM enables fast evaluation of the pore structure and separation between matrix and fat. Non-destructive 3D visualization with XRM is thus ideal to support feed engineering, as well as monitoring feed production.

Related Videos

How to use handheld and portable XRF (HH-XRF , pXRF) to to identify physical contamination in food products

Physical Contaminant Spectral Fingerprinting for Food Production