In-Situ SEM and TEM NanoTribology with Hysitron PicoIndenter

Learn about the applications of high-resolution in-situ tribology testing.

Learn from leading experts about in-situ nanomechanical and tribological characterization — including how to quantify friction, adhesion, wear, and more.

Webinar Summary

In this webinar:

- Dr. Sanjit Bhowmick introduces nanoTribological modules of PI 89 SEM and PI 95 TEM PicoIndenter and briefly highlights various examples of interesting applications.

- Prof. Min Zou presents an in-situ SEM tribology study of surfaces with 3D textures fabricated by additive manufacturing techniques.

- Prof. Tevis Jacobs showcases how TEM studies can deepen the understanding of deformation mechanisms at nanoscale sliding contacts.

Find out more about the technology featured in this webinar or our other solutions for In-Situ SEM and TEM NanoTribology:

Additional Information

Why Seek to Understand Nanoscale Surface Changes

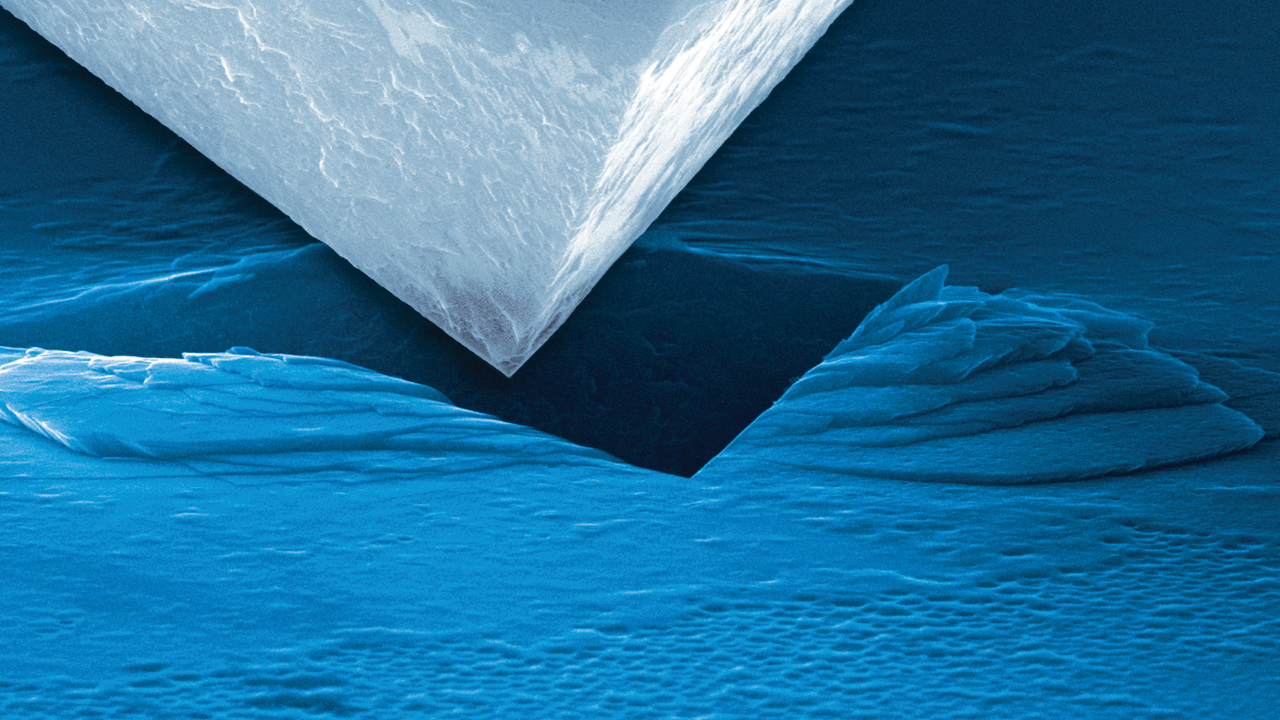

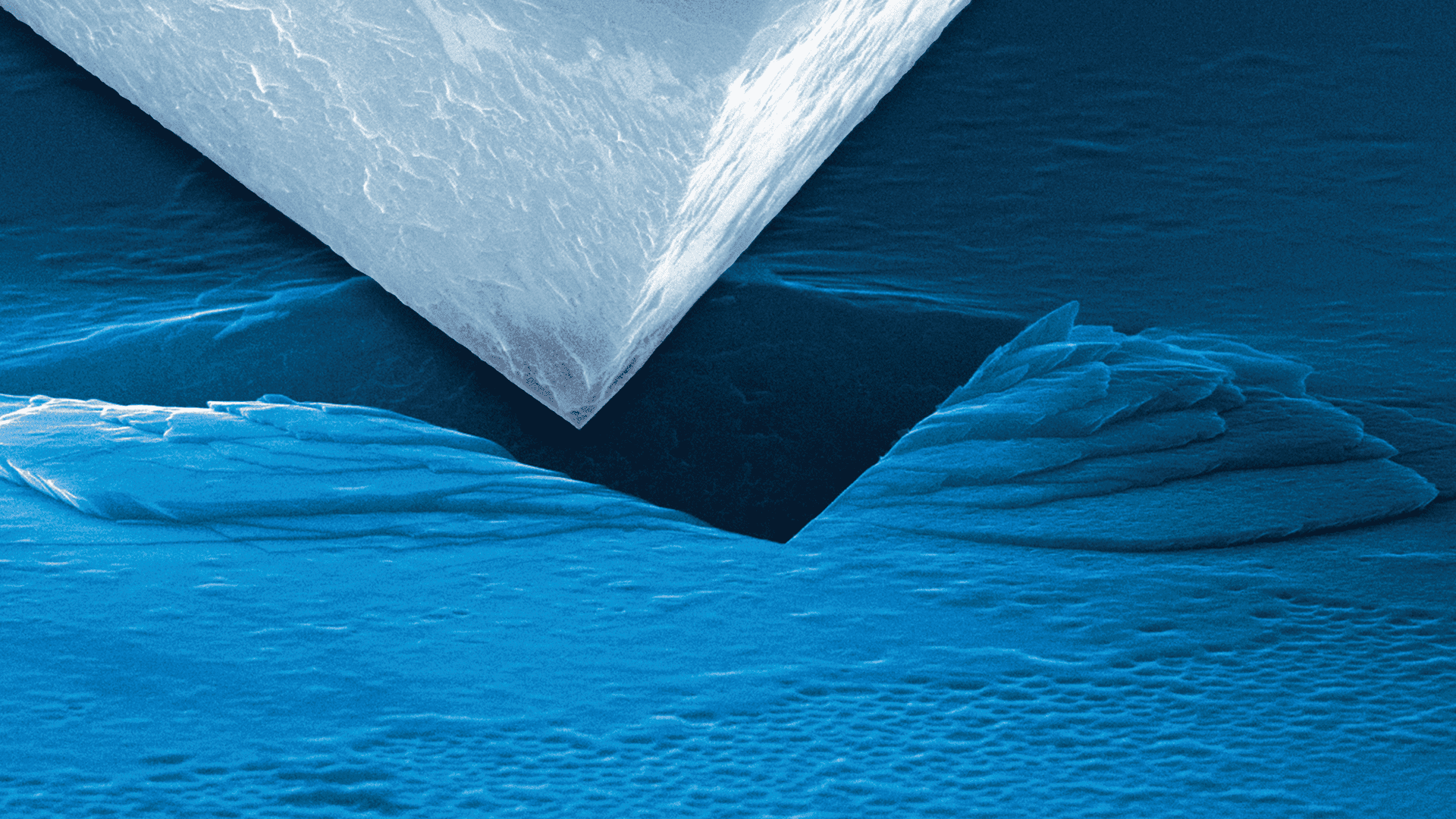

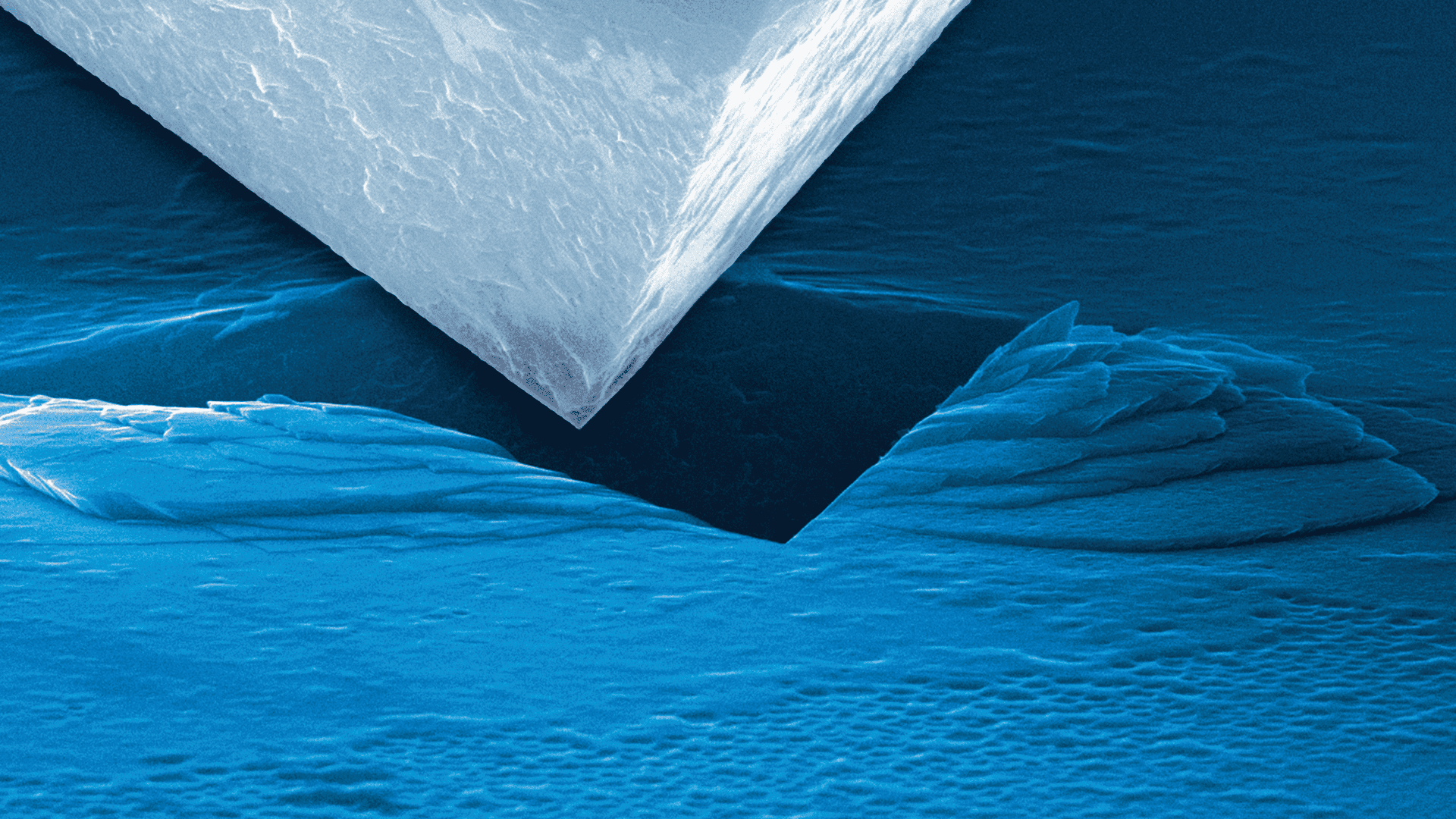

Tribological measurements benefit directly from in-situ techniques which shed light on deformation processes occurring at the sliding interface. In addition to enabling direct observation of wear evolution, in-situ tribology can also be used for studies of friction, tribochemical reactions, interfacial adhesion, abrasion resistance, and nanoparticle rolling.

Applications of in-situ tribology testing can include quantifying (among others):

- Scratch resistance, coefficient of friction, interfacial shear strength and adhesion of films and coatings;

- Shear forces to pillars, solder bumps, beams, MEMS devices, and oriented crystalline materials;

- Particle-substrate Interaction, friction between a single micro- or nanoparticle and the supporting substrate.

How Hysitron Picoindenter Instruments Help

Despite being applicable across a wide range of sample types and industries, until recently, in-situ nanoscale mechanical testing has been limited to the application of purely normal forces. That is, quantitative nanoindentation, compression, bending, and tensile loading coupled with direct SEM observation are accomplished by varying the tip and sample geometry. Often, however, testing in more than one dimension is required to fully understand the performance of a material system, especially when dealing with the tribological properties of a material.

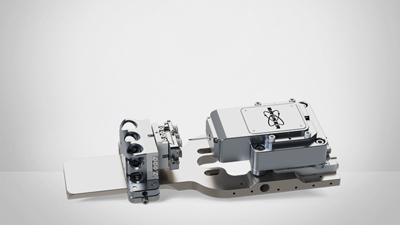

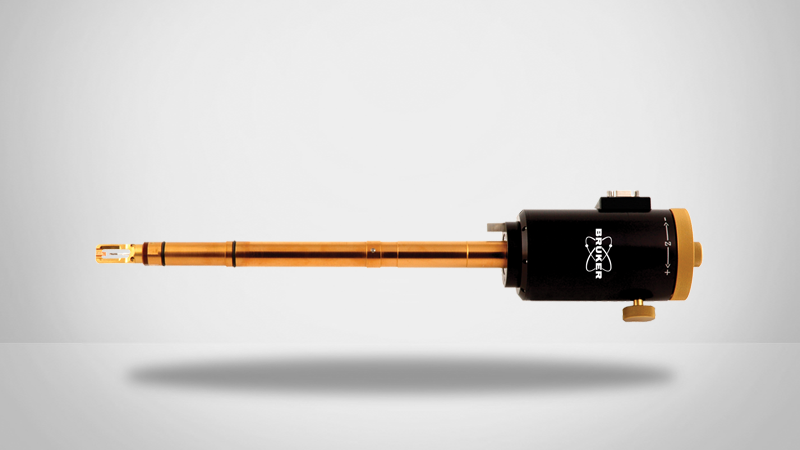

In support of engineers' and researchers' growing need for increased multi-directional functionality, the nanoTribology module for Bruker's Hysitron PI 95 TEM PicoIndenter and Hysitron PI 89 SEM PicoIndenter instruments enables high-resolution measurements with simultaneous normal and lateral force/displacement sensing.

Featured Products and Technology

Speakers

Sanjit Bhowmick, Ph.D.

Senior Staff Scientist, Bruker

Dr. Sanjit Bhowmick is a Senior Staff Scientist at Bruker. His research interest includes understanding microstructure and mechanical property correlation of advance nanostructured materials using in-situ SEM and TEM nanomechanical techniques. He has published more than 80 papers in peer-reviewed journals.

Min Zou, Ph.D., Professor, Mechanical Engineering, University of Arkansas

Tevis Jacobs, Ph.D., Professor, Swanson School of Engineering, University of Pittsburgh