Elemental Analysis of Battery Components and Materials Using Handheld XRF, Micro-XRF and SEM-EDS

What to expect?

Batteries are essential for modern technology, powering devices from smartphones to electric vehicles. Ensuring the quality and safety of batteries is crucial to prevent failures and hazards. Quality control throughout the batteries’ life cycle involves examining the anode, cathode, electrolyte, and separator materials, as well as materials to be recycled.

As a manufacturer of handheld XRF, micro-XRF, and SEM-EDS instruments, we aim to compare how these different analytical techniques can address various analytical questions about battery components:

- Handheld XRF: Quickly identifies elemental composition and detects impurities in raw materials and finished components.

- micro-XRF: Provides detailed elemental mapping of relatively large areas, useful for analyzing specific features or inclusions in battery materials.

- SEM-EDS: Offers high-resolution imaging and precise elemental analysis, crucial for verifying material composition and structural integrity.

- SEM based micro-XRF: As an add-on tool, combines the advantages of EDS and micro-XRF.

In this webinar, we will present results obtained with the different analytical techniques on battery precursor materials and various manufactured electrodes. We will explain the obtained results in terms of elemental sensitivity, detection limits, sample volume/area, spatial resolution and measurement time, while also addressing general limitations that originate from the different physical principles behind the techniques. Understanding these differences helps in selecting the right method for specific analytical needs.

Who should watch?

- Battery technology experts and engineers.

- People working in battery research or battery manufacturing.

- People interested in learning about the differences between X-ray and electron excitation-based elemental analysis.

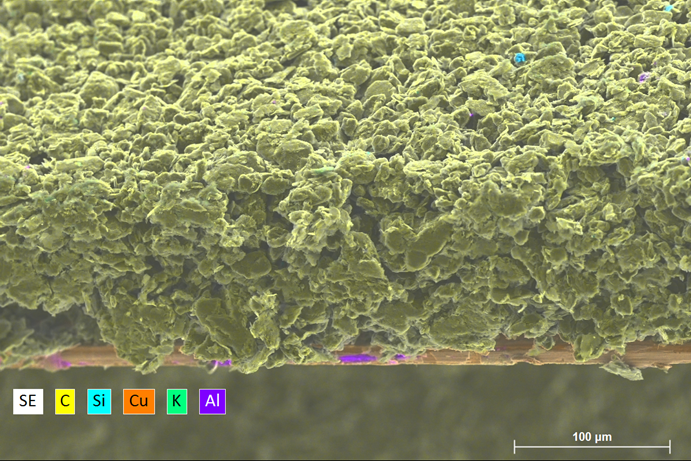

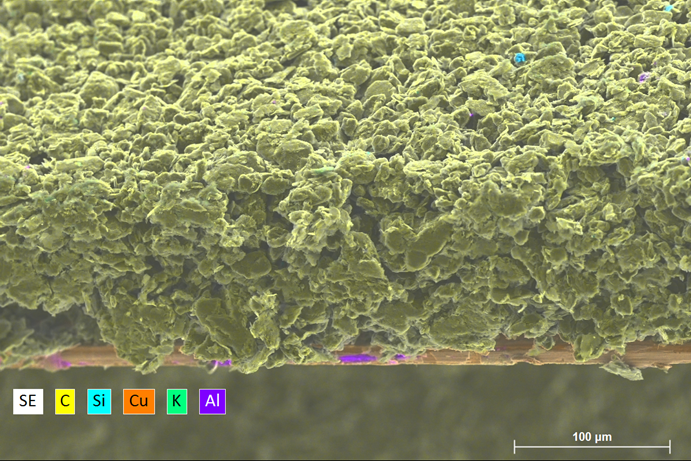

Graphite electrode on Cu-foil viewed in cross section: EDS mapping with QUANTAX FlatQUAD system reveals contaminants within short measurement time.

Speakers

Dr. Igor Németh

Application Scientist EDS, Bruker Nano Analytics

Falk Reinhardt

Senior Application Scientist micro-XRF, Bruker AXS

Dr. Kathrin Schneider

Application Scientist Handheld XRF - Bruker Nano Analytics

Dr. Yang Yang

Application Scientist - micro-XRF on SEM and EDS, Bruker Electron Microscope Analyzers

Watch this On-Demand Webinar

Please enter your details below to gain on-demand access to this webinar.