Battery Research

Shedding Light on the Workings of Energy Storage Materials

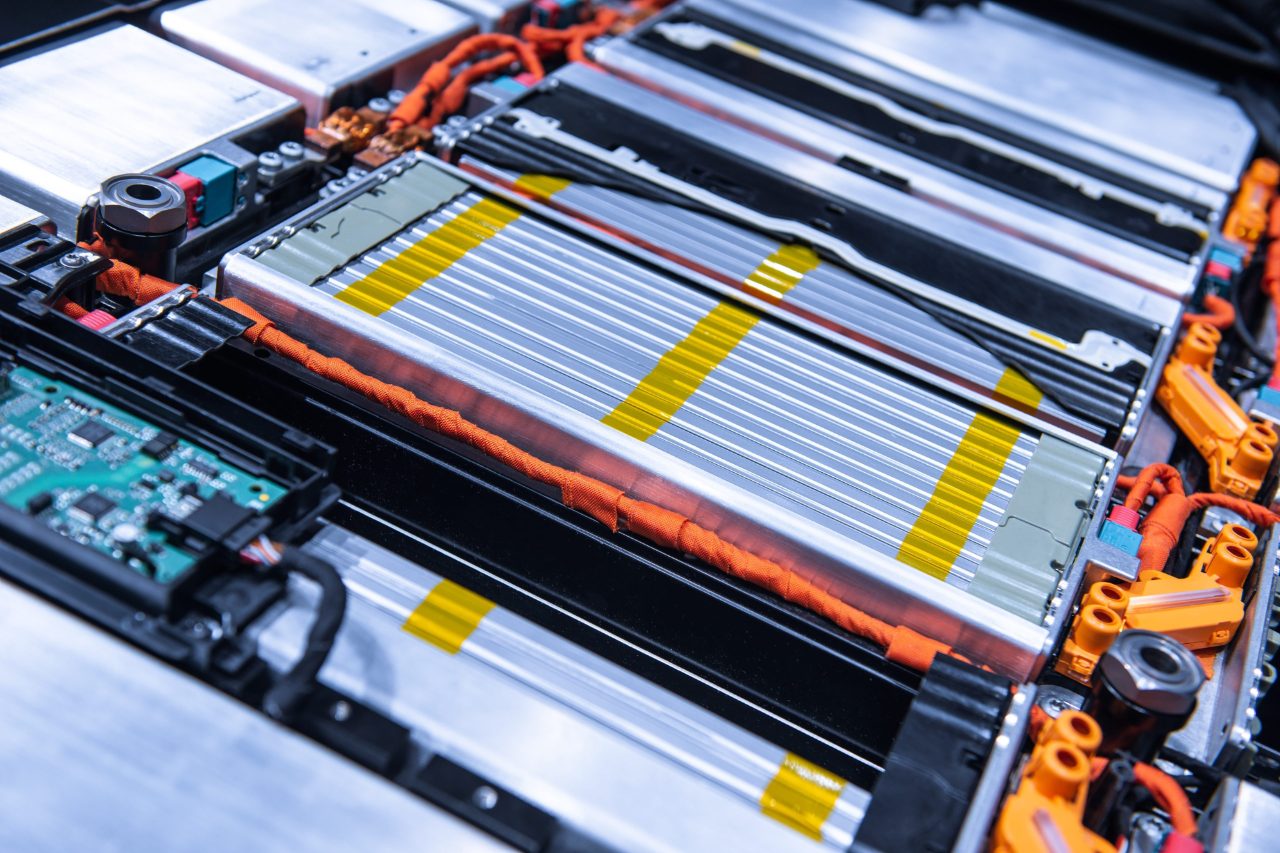

Energy generation and energy storage related applications require some of today’s most complex materials development initiatives to meet efficiency and reliability targets. Many of our electronic devices, from laptops to smartphones, are powered by rechargeable lithium-ion (Li-ion) batteries, and they could soon extend into many other areas as well. This includes transport, through the ongoing development and adoption of electric vehicles. New materials are continuously being developed that transform the ways we capture, transmit, and store energy.

The performance of any battery, whether in terms of its capacity, lifetime or energy density, is ultimately down to the intrinsic properties of the materials that comprise its anode, cathode, electrolyte and SEI. Bruker has developed a comprehensive suite of characterization techniques to enable scientist to understand and optimize the physical and chemical properties, performance and stability of all battery components and the fully assembled battery cells.

Read on to find out how Atomic Force Microscopy, FTIR Spectroscopy, Nanomechanical Testing, X-ray Diffraction, Raman Microscopy, X-ray Microscopy, Magnetic Resonance and X-ray Spectroscopy shed light on the workings of energy storage materials.

In-situ Characterization

Investigating solutes and electrodes

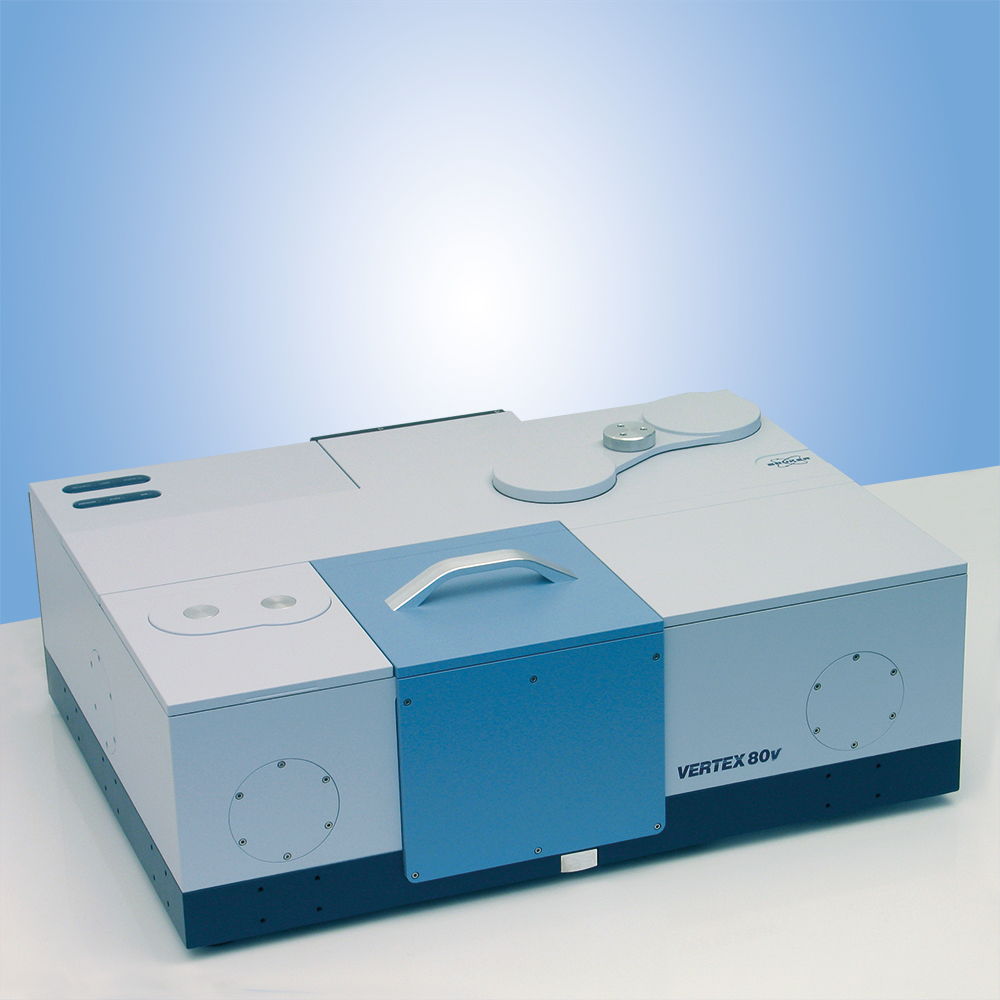

Researchers can in-situ monitor the electrochemical process in the solutes and electrodes of a lab-level battery model system. These model systems are not ready battery products, but one has the possibility to tune the anode, cathode materials, the electrolyte composition, temperature etc. during a programmed voltage cycle. FTIR spectroscopy is synchronised with electrochemical reaction. As result IR spectra over time / potential are collected. The combination of FTIR spectroscopy with electrochemistry offers insight in the molecular change and the reaction process of the studied molecules in addition to the electrochemical response of the experiment.

Follow battery cell behavior during cycling

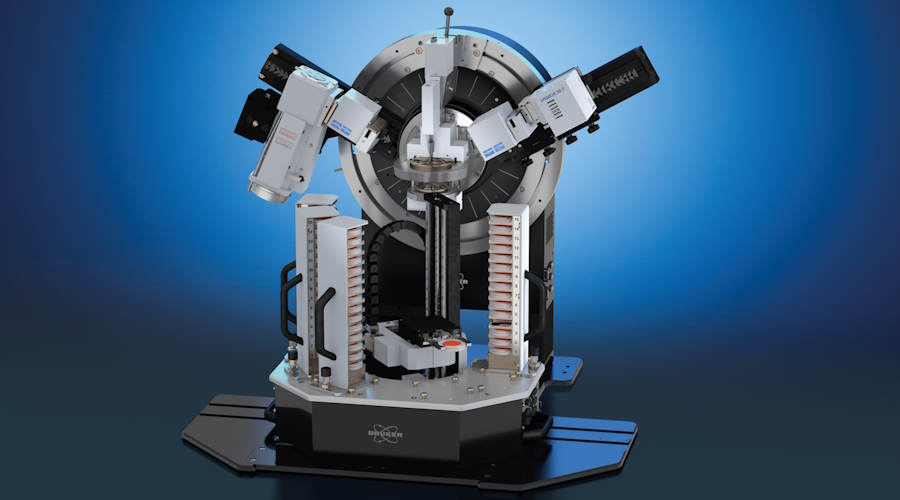

During charge/ discharge, the cathode and anode of every battery cell undergo constant changes, e.g. due to the insertion of Li-cations. With X-ray diffraction (XRD), both the changing phase composition and the evolution of the crystal structure can be followed simultaneously. This allows researchers to understand new energy storage materials on an atomic level, follow the reaction that occur during cycling and monitor degradation behaviour to improve battery performance.

Our X-ray diffractometers support your research and development in battery materials, from ex-situ analysis of isolated cathode and anode materials, to the in-operando investigation of fully functional coin- and pouch-cells.

Observing Li-dendrite growth in situ

Lithium dendrite growth is one of the biggest problems affecting the safety of Li-ion batteries, but probing the initial stages of dendrite growth is difficult due to the reactive and fragile nature of lithium compounds, especially when studying growth at the solid electrolyte interface (SEI).

Using atomic force microscopy with electrochemical mode, the morphological evolution of the electrode surface under potential control can be traced. These experiments reveal different Li-deposition on graphite for different electrolytes, providing a deeper understanding of the underlying mechanism of dendritic growth in Li-batteries.

Solid-state NMR probes for in situ research on energy storage materials

In situ solid-state nuclear magnetic resonance (NMR) spectroscopy can provide valuable insights into the structure, dynamics, and electrochemical properties of battery materials. It allows researchers to study the behavior of materials during battery operation, which can help in the development of new and improved battery designs.

For example, in situ NMR spectroscopy can be used to investigate the behavior of the electrolyte and electrode materials during battery charging and discharging cycles. This information can be used to optimize the performance of the battery and to identify any potential issues that may arise during operation.

In addition, in situ NMR spectroscopy can also be used to study the degradation mechanisms of battery materials over time. This can help in the development of more durable and longer-lasting batteries.

Overall, in situ solid-state NMR spectroscopy is a powerful tool for battery research and manufacturing, as it allows for a better understanding of the fundamental processes that govern battery performance and can help to guide the development of next-generation battery technologies.

Ex-Situ and Failure Analysis

FT-IR based Analysis of Battery Gases

Lithium-ion batteries are widely used storage systems that play a crucial role in electric vehicles. However, in the event of a failure or thermal runaway, these batteries can release various toxic and hazardous gases. This underscores the necessity of monitoring the gases emitted by batteries in diverse scenarios, such as charging, overheating, or physical damage. The MATRIX II-MG and OMEGA 5 gas analyzers based on the FT-IR technology are well-suited for analyzing battery gases, offering rapid, accurate, and real-time analysis of gas mixtures. Consequently, these gas analyzers are indispensable for fire departments, battery cell manufacturers, battery recyclers, and transporters as they aid in detecting and analyzing potentially dangerous gases during emergencies.

Studying electrochemical side reactions by laser desorption/ionization imaging

In the emerging fields of electroorganic synthesis and battery research, electrochemical side reactions on the active surface of electrodes represent a major challenge for efficiency and reproducibility.

Often, the undesired polymerization of one or more compounds on the active surface of electrodes is observed. These polymers tend to adsorb on the electrode leading to a passivation of the active surface, which is often referred to as “electrode fouling”.

Mass spectrometric imaging using the timsTOF fleX enables the identification and the spatially resolved visualization of the adsorbed side products. Hence, timsTOF fleX-based imaging allows the investigation of electrode fouling and provides valuable insight into electrochemical reaction pathways.

Increasing battery safety

Mechanical damage, including brittle failure of the electrodes and separator penetration, can give rise to dramatic releases of stored energy, including battery fires. Moreover, failures of coatings, mechanical (or ion) induced swelling and stiffening, stresses arising from fabrication, and mechanical stresses and damage from multiple charge-discharge cycles pose significant challenges for new device development and integration. Thus, for both safety and performance reasons, it is necessary to understand how these devices perform mechanically, including each component at the appropriate size scale.

Nanomechanical testing of battery materials provides quantitative characterization for emerging materials and deeper insight for improving mechanical performance.

Carbon analysis in flexible electrodes

Batteries using LiFePO4 (LFP) based cathodes are known to be very safe and show no risk of thermal runaway but have a low electrical conductivity, limiting the performance at high charge/ discharge rates. A very thin carbon coating on the LFP particles can improve its conductivity. The anodic stability of carbon coated cathode materials can be studied with Raman Spectroscopy, which demonstrates the homogeneity of the coating.

All components of a battery like anode/cathode materials and electrolytes can be analyzed with a very high lateral resolution using Raman microspectroscopy, both ex- and in -situ. Carbon is widely used in batteries. Raman spectra can be used to distinguish its allotropes and provide further information like defect concentration.

Magnetic Resonance technologies are broadly applied in batteries research and production

Magnetic resonance technology provides a valuable tool for the batteries industry by enabling researchers to gain in-depth insights into the chemical and physical processes that govern battery performance. This technology can be effectively applied as well to the value chain and supply chain of batteries manufacturing to ensure the consistent quality of battery components and materials, including electrodes, electrolytes, and separators. Furthermore, it can be utilized to monitor battery production processes and identify any defects or inconsistencies that may compromise battery performance or safety. By leveraging magnetic resonance technology, batteries manufacturers can enhance their production capabilities and develop more efficient, durable, and cost-effective battery solutions that meet the growing demands of the market.

Whether you are a battery manufacturer or a researcher, Magnetic Resonance can help achieving innovation in the fast-paced world of batteries research and manufacturing.

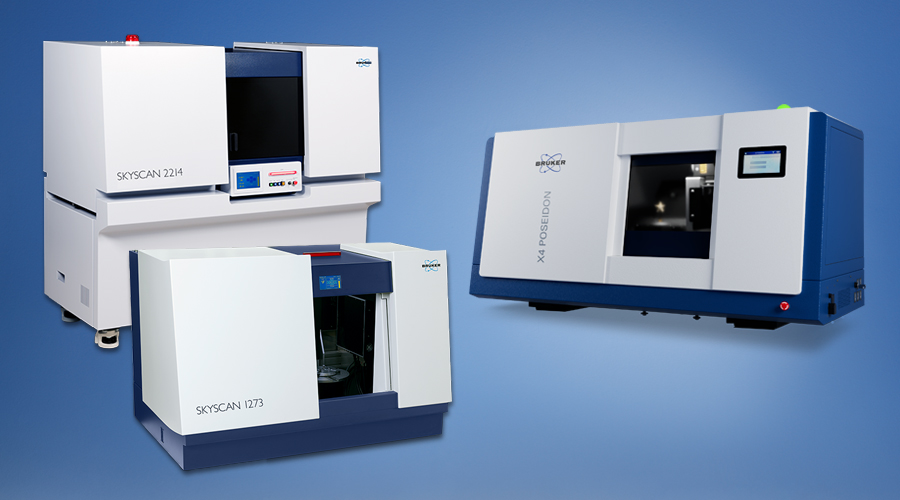

Verify structural integrity and research microstructure of electrodes

X-ray microscopy enables to non-destructively visualize the internal 3D structure of batteries and fuel cells. XRM is therefore a great tool to help understanding failure mechanisms by monitoring the internal alignment of components such as electrode separation over the battery life time, or in stress tests.

The electrode microstructure of modern high-performance batteries such as Li-ion batteries significantly impacts key properties such as cycle life time and capacity. A lot of efforts therefore go into careful optimization of processing parameters to tease out the best battery performance. XRM as multi-scale analysis technique supports advanced battery research since it can reveal at high resolution the microstructure of the individual anode and cathode layers.

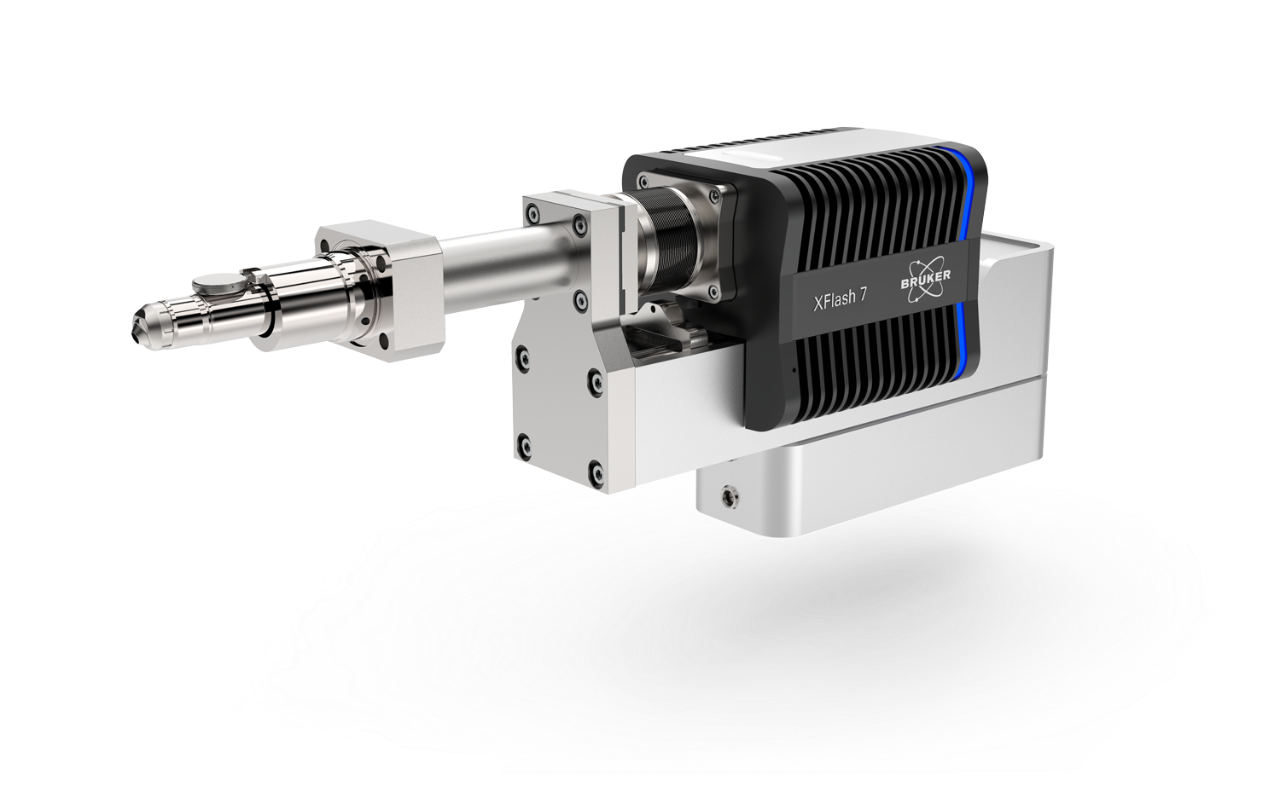

Elemental mapping in lead-acid battery electrodes

Lead-acid batteries (accumulators) are rechargeable devices for storing electric energy generated by electrochemical processes. The batteries consist of electrodes made of lead (Pb) and lead dioxide (PbO2) and dilute sulfuric acid (37% H2SO4) as electrolyte. During discharge of lead-acid batteries, finely dispersed lead sulfate (PbSO4) forms on electrodes in a process that is reversed by recharging. However, under certain conditions, permanent deposits can also form on the electrodes. X-ray element maps acquired by WDS are ideal for investigating the nature and spatial distribution of sulfation deposits leading to battery failure.

Automate Your Battery Research

that significantly enhance research and operational outcomes. Automated systems handle repetitive and time-consuming tasks, allowing researchers to dedicate more time to critical thinking and innovation.

This leads to faster data collection and analysis, enabling quicker identification of material properties and ensuring the development of safer and more efficient batteries.

Additionally, our automation solutions ensures reproducibility and accuracy in experiments, which is crucial for validating results and maintaining high standards of quality control. By reducing manual errors and increasing throughput, our automation solutions help battery research institutions maximize their resources and achieve their goals more efficiently.