電池研究

エネルギー貯蔵材料の働きを解明

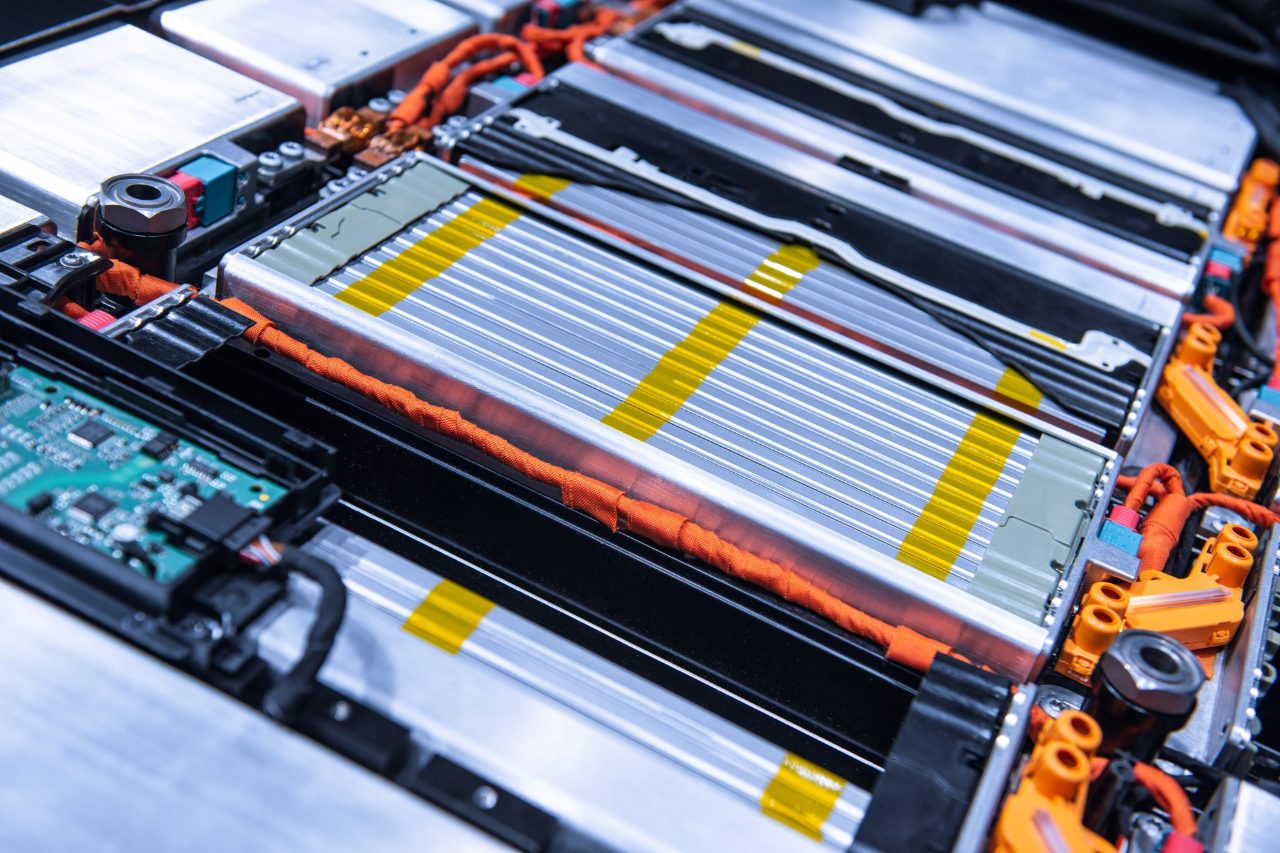

エネルギー生成およびエネルギー貯蔵関連の応用分野では、効率性と信頼性を達成するため、現代で最も複雑な材料開発プロジェクトが求められています。ノートパソコンからスマートフォンに至るまで、私たちの電子機器の多くは充電式リチウムイオン(Li-ion)電池で駆動されており、近い将来、電気自動車の開発と普及を通じて輸送分野を含む他の多くの領域へも拡大する可能性があります。エネルギーの捕捉、伝達、貯蔵の方法を変革する新素材が絶えず開発されています。

あらゆる電池の性能は、容量、寿命、エネルギー密度いずれの観点においても、最終的には負極、正極、電解質、SEI(Solid Electrolyte Interphase, 固体電解質界面膜)を構成する材料の固有特性に依存します。ブルカーは、科学者が電池構成部品および組み立て済み電池セル全体の物理的・化学的特性、性能、安定性を理解し最適化できるよう、包括的な特性評価技術群を開発しました。

原子間力顕微鏡(AFM)、フーリエ変換赤外分光法(FT-IR)、ナノ機械試験、X線回折、ラマン顕微鏡、X線顕微鏡、磁気共鳴、X線分光法が、エネルギー貯蔵材料の働きを解明する仕組みについて、以下詳しくご紹介します。

研究成果と運用効率を大幅に向上させる自動化機能を装置に追加

自動化システムが反復的で時間のかかる作業を処理してくれるため、研究者は検証的および革新的思索により多くの時間を割くことができます。

これによりデータ収集と分析が迅速化され、材料特性の早期特定が可能となり、より安全で効率的な電池の開発が保証されます。

さらに、ブルカーの自動化ソリューションは実験の再現性と精度を確保します。これは結果の検証と高品質管理基準の維持に不可欠です。手作業によるエラーを削減し処理能力を向上させることで、ブルカーの自動化ソリューションは電池研究機関がリソースを最大限に活用し、目標をより効率的に達成することを支援します。

In-situ 特性評価

溶質と電極の調査

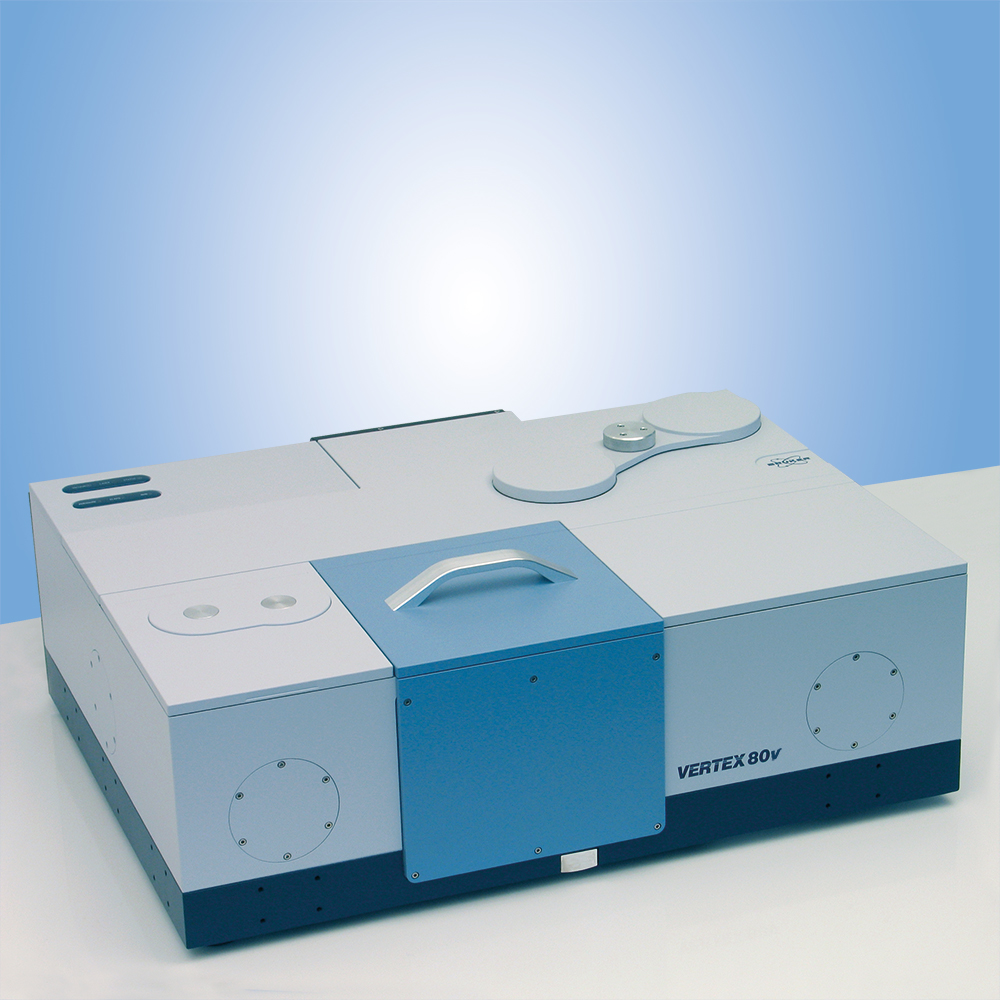

研究者はラボレベルの電池モデルシステムにおいて、溶質と電極内の電気化学的プロセスをIn-situでモニタリングできます。これらのモデルシステムは市販電池製品と違い、プログラムされた電圧サイクル中に負極・正極材料、電解質組成、温度などを調整することが可能です。FT-IR分光法は電気化学反応と同期されます。その結果、時間/電位に応じたIRスペクトルが収集されます。FT-IR分光法と電気化学の組み合わせにより、実験の電気化学的応答に加え、研究対象分子の分子変化と反応プロセスに関する知見が得られます。

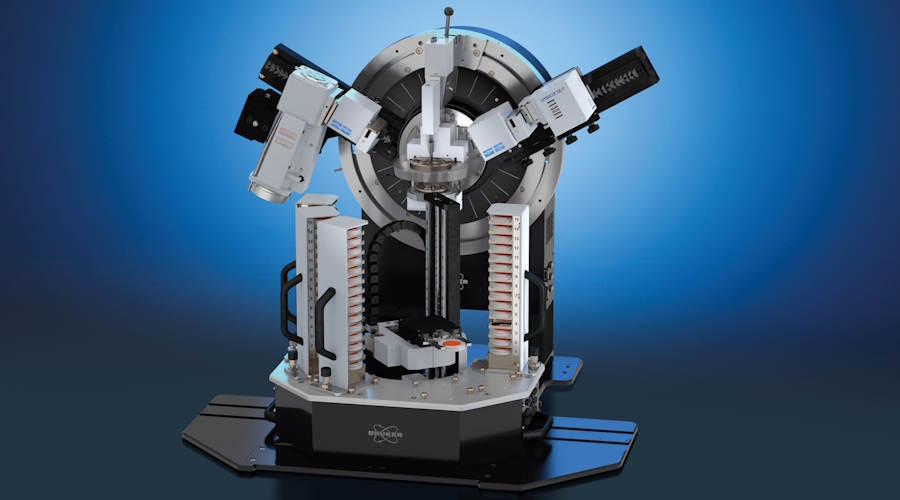

充放電サイクル中の電池セル内結晶情報モニタリング

充放電サイクルにおいて、電池セルの正極と負極はリチウムイオンの脱挿入により絶えず変化します。X線回折(XRD)を用いることで、変化する相構成と結晶構造の変化を同時にモニターできます。これにより、新たなエネルギー貯蔵材料の構造について原子レベルで理解し、充放電中に発生するさまざまな反応を検出、劣化挙動を評価して電池性能の向上につなげることができます。

ブルカーのX線回折装置は、正極・負極材料単体でのex-situ分析から、電池として動作する状態のコイン型・パウチ型電池セルのOperando解析まで、電池材料の研究開発を包括的に支援します。

Observing Li-dendrite growth in situ

Lithium dendrite growth is one of the biggest problems affecting the safety of Li-ion batteries, but probing the initial stages of dendrite growth is difficult due to the reactive and fragile nature of lithium compounds, especially when studying growth at the solid electrolyte interface (SEI).

Using atomic force microscopy with electrochemical mode, the morphological evolution of the electrode surface under potential control can be traced. These experiments reveal different Li-deposition on graphite for different electrolytes, providing a deeper understanding of the underlying mechanism of dendritic growth in Li-batteries.

エネルギー貯蔵材料のIn-situ解析のための固体NMRプローブ

固体状態の核磁気共鳴(固体NMR)分光法を用いたin-situ測定では、電池材料の構造、ダイナミクス、電気化学的特性に関する貴重な知見を提供します。これにより研究者は電池動作中の材料挙動を研究でき、新規かつ改良された電池設計の開発に寄与します。

例えば、 in-situ NMR分光法は、電池の充放電サイクル中の電解質および電極材料の挙動を調査するために使用できます。この情報は、電池の性能を最適化し、動作中に発生する可能性のある潜在的な問題を特定するために活用できます。

さらに、 in-situ NMR分光法は、時間経過に伴う電池材料の劣化メカニズムの研究にも使用できます。これは、より耐久性が高く長寿命な電池の開発に役立ちます。

全体として、in-situ 固体NMR分光法は、電池性能を支配する基本プロセスをより深く理解し、次世代電池技術の開発を導く上で有用なため、電池研究・製造における強力なツールです。

Ex-situおよび故障解析

FT-IRに基づく電池ガス分析

リチウムイオン電池は電気自動車において重要な役割を担う、広く普及した蓄電システムです。しかし故障や熱暴走が発生した場合、様々な有毒・有害ガスを放出する可能性があります。このため充電時、過熱時、物理的損傷時など多様なシナリオにおける電池からのガス放出を監視する必要性が強調されます。FT-IR技術に基づくMATRIX II-MGおよびOMEGA 5ガス分析装置は、電池ガス分析に最適であり、ガス混合物の迅速・正確・リアルタイムな分析を実現します。したがって、これらのガス分析装置は、緊急時に潜在的に危険なガスの検出と分析を支援するため、消防署、電池セルメーカー、電池リサイクル業者、輸送業者にとって不可欠な存在です。

Studying electrochemical side reactions by laser desorption/ionization imaging

In the emerging fields of electroorganic synthesis and battery research, electrochemical side reactions on the active surface of electrodes represent a major challenge for efficiency and reproducibility.

Often, the undesired polymerization of one or more compounds on the active surface of electrodes is observed. These polymers tend to adsorb on the electrode leading to a passivation of the active surface, which is often referred to as “electrode fouling”.

Mass spectrometric imaging using the timsTOF fleX enables the identification and the spatially resolved visualization of the adsorbed side products. Hence, timsTOF fleX-based imaging allows the investigation of electrode fouling and provides valuable insight into electrochemical reaction pathways.

Increasing battery safety

Mechanical damage, including brittle failure of the electrodes and separator penetration, can give rise to dramatic releases of stored energy, including battery fires. Moreover, failures of coatings, mechanical (or ion) induced swelling and stiffening, stresses arising from fabrication, and mechanical stresses and damage from multiple charge-discharge cycles pose significant challenges for new device development and integration. Thus, for both safety and performance reasons, it is necessary to understand how these devices perform mechanically, including each component at the appropriate size scale.

Nanomechanical testing of battery materials provides quantitative characterization for emerging materials and deeper insight for improving mechanical performance.

フレキシブル電極における炭素分析

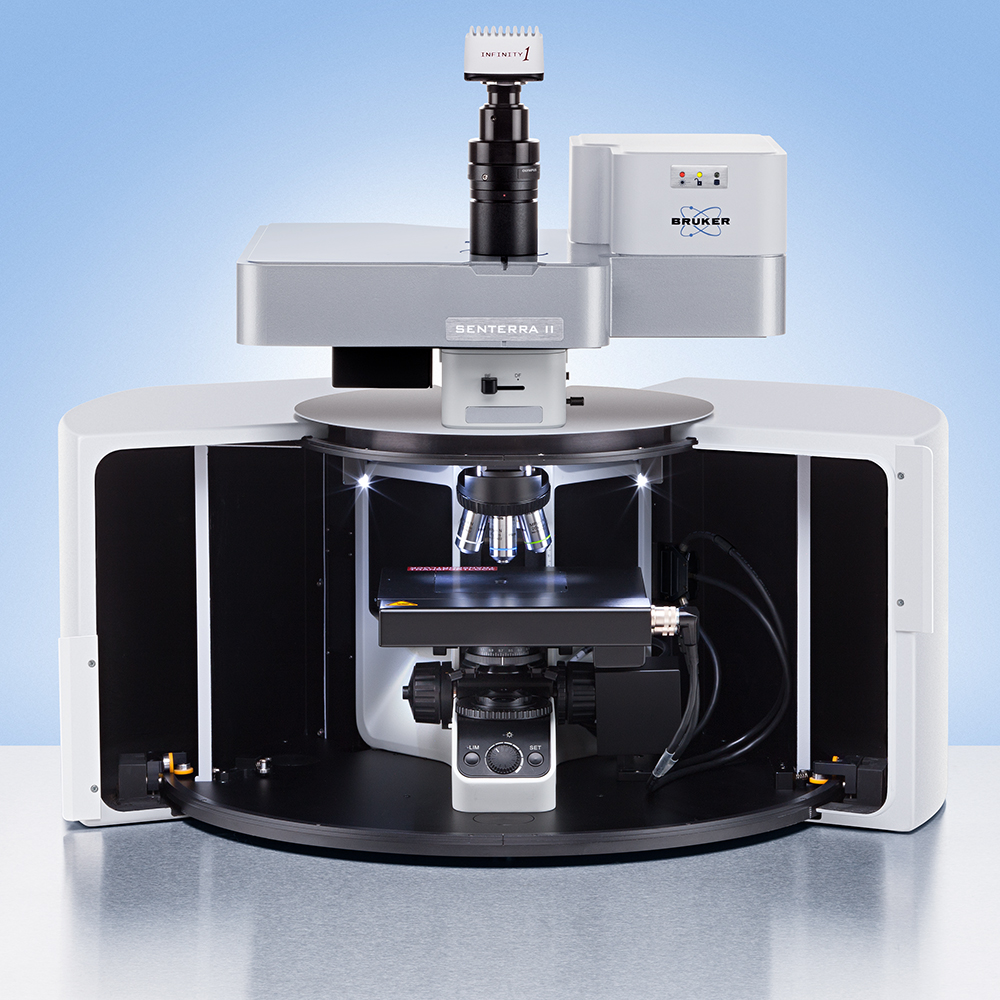

LiFePO₄(LFP)系正極を用いた電池は、熱暴走のリスクが極めて低く、安全性に優れていることで知られています。しかし、LFPは電気伝導性が低いため、高い充放電率では性能が制限されます。この課題を解決するため、LFP粒子に非常に薄い炭素コーティングを施すことで導電性を向上させることが可能です。さらに、炭素でコーティングされた正極材料の安定性はラマン分光法によって評価でき、コーティングの均一性を確認する指標としても有効です。

電池の構成要素である正極/負極材料や電解質などは、顕微ラマン分光法を用いることで、特定の状態を評価するex-situと、動作させながら評価するin-situのどちらでも、非常に高い空間分解能で分析することができます。炭素は電池に広く利用されていますが、ラマンスペクトルによってその同素体を識別し、欠陥濃度などの追加情報を得ることが可能です。

電池の研究・製造における磁気共鳴技術の広範な応用

磁気共鳴技術は、研究者が電池性能を支配する化学的・物理的プロセスを深く理解することを可能にし、電池産業にとって貴重なツールを提供します。この技術は、電池製造のバリューチェーンおよびサプライチェーンにも効果的に適用でき、電極、電解液、セパレータを含む電池部品・材料の一貫した品質を確保します。さらに、磁気共鳴技術は電池製造工程の監視にも活用でき、電池性能や安全性を損なう可能性のある欠陥や不整合を特定します。この技術を活用することで、電池メーカーは生産能力を強化し、市場の増大する需要に応える効率的で耐久性が高く、コスト効率に優れた電池ソリューションを開発できます。

電池メーカーであれ研究者であれ、磁気共鳴は急速に進化する電池研究・製造の世界において革新を実現するお手伝いをします。

構造安全性の検証と電極の微細構造研究

3D X線顕微鏡(XRM)は、電池や燃料電池の内部の三次元構造を非破壊で可視化することができます。電池寿命期間中や応力試験において、電極分離などの構成要素の内部配置を観察することで、故障メカニズムの解明に極めて有用なツールとなります。

リチウムイオン電池などの現代の高性能電池において、電極の微細構造はサイクル寿命や容量といった主要な特性に大きく影響します。そのため、最高の電池性能を引き出すために、加工条件の精密な最適化に多くの努力が注がれています。XRMはマルチスケール解析技術として、個々の負極層および正極層の微細構造を高解像度で明らかにできるため、先進的な電池研究を支えています。

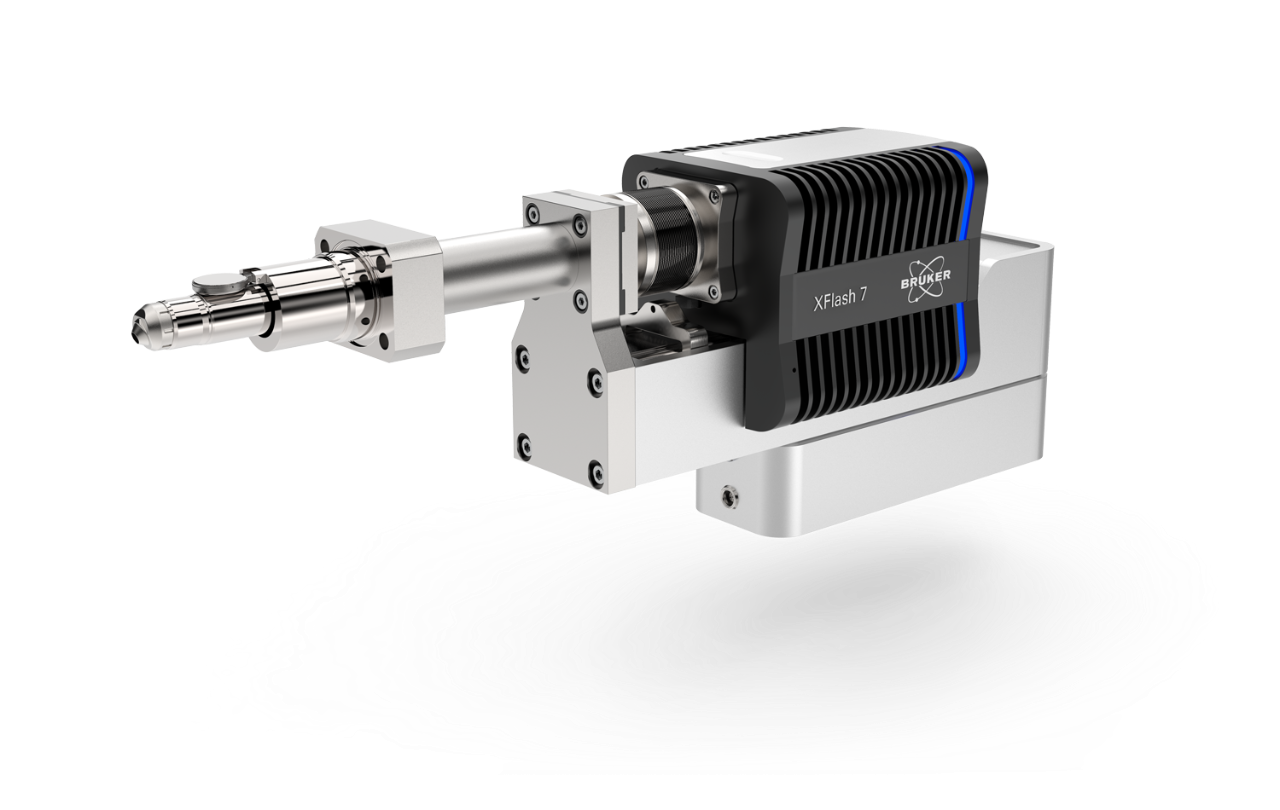

鉛蓄電池電極の元素マッピング

鉛蓄電池は、電気化学的プロセスによって生成される電気エネルギーを蓄える充電式電池です。鉛(Pb)と二酸化鉛(PbO2)で作られた電極と、電解質としての希硫酸(37% H2SO4)で構成されています。鉛蓄電池の放電時には、電極上に微細な分散した硫酸鉛(PbSO4)が形成されますが、このプロセスは充電によって逆転します。ただし特定の条件下では、電極上に永久的な堆積物が生成される場合があります。WDSで取得したX線元素分布マップは、電池故障を引き起こす硫酸化堆積物の性質と空間分布を調査するのに理想的です。

Automate Your Battery Research

that significantly enhance research and operational outcomes. Automated systems handle repetitive and time-consuming tasks, allowing researchers to dedicate more time to critical thinking and innovation.

This leads to faster data collection and analysis, enabling quicker identification of material properties and ensuring the development of safer and more efficient batteries.

Additionally, our automation solutions ensures reproducibility and accuracy in experiments, which is crucial for validating results and maintaining high standards of quality control. By reducing manual errors and increasing throughput, our automation solutions help battery research institutions maximize their resources and achieve their goals more efficiently.