Battery Manufacturing & Quality Control

Advancing Battery Production: From Raw Materials to Next-Generation Cells

Energy storage systems are critical for our transition to a low carbon economy, with the shift towards green energy driving unprecedented demand for both higher-performing batteries and greater production capacities.

In today’s fast-evolving battery industry, precision and efficiency are essential. Bruker offers a comprehensive portfolio of cutting‑edge analytical solutions for the battery industry. These solutions support every manufacturing stage, from raw materials and pCAM characterization to cell quality control, operando measurements and battery recycling.

Bruker's solutions deliver value from start to finish, with each of our analytical technologies finding multiple applications throughout the battery production process.

Continue reading to learn more about using our analytical solutions to improve battery quality and performance at each battery manufacturing stage, or jump to the stage you are interested in using the navigation below:

Inspection & Quality Control of Raw Materials

The inspection of raw materials and precursors to verify their identity and quality is crucial for the production of reliable, high-performance batteries. High-level quality assurance - from material identification to contamination mapping - is practical and reliable using Bruker’s portfolio.

Our solutions include X-Ray Fluorescence (XRF) spectrometers for fast and accurate composition verification, electron microscope-based detectors for spatial elemental and structural analysis down to the nanoscale, and magnetic resonance spectrometers (NMR, EPR) to assess raw materials at molecular and atomic levels.

Purity Analysis & Material ID of Metals, Salts and Wet Precursors

The purity of the raw materials, such as metals, salts, and wet precursors, used in battery production is critical. Even minor impurities can cause battery capacity loss, side reactions, or reduced cell life.

XRF delivers rapid, quantitative and non-destructive elemental analysis for material verification and contaminant detection, even at trace levels.

XRF is routinely used in the battery industry to:

- Determine the Ni:Co:Mn ratio in NCM sulfate solutions (Figure 2) to ensure correct cathode composition.

- Perform quality control of copper and aluminum foils.

- Detect impurities in graphite powders that may affect anode function.

- Determine the purity and stoichiometry of conductive salts and wet precursors, supporting reliable downstream processing.

Integrating XRF into quality workflows helps manufacturers maintain high standards and minimize production risks. Bruker's provides both advanced XRF systems with intuitive software to streamline routine analysis as well as handheld XRF solutions for flexible operation at a factory's receiving dock.

Graphite Quality Control using 3D Imaging

Graphite is the precursor for anodes in lithium-ion batteries, providing the structure for lithium intercalation and influencing conductivity and cycle life. Quality control of the graphite is essential because variations in particle size, shape, or internal defects can lead to uneven coating, reduced performance, and safety risks.

X-Ray Microscopy (XRM) enables the non-destructive 3D imaging of graphite particles, allowing manufacturers to check particle size distribution, shape uniformity, and detect foreign inclusions or voids.

Bruker’s X4 POSEIDON, with sub-micron resolution and advanced segmentation tools, deliver fast, accurate morphological analysis without the need for physical sectioning. The use of 3D imaging in graphite quality control helps ensure the production of high-quality anodes.

Characterization of Graphite using EPR

Graphite’s low-voltage open-circuit potential makes it prone to metallic lithium deposition during charging, especially at low temperatures, high charge rates, and high states of charge.

Electron Paramagnetic Resonance (EPR) spectroscopy is ideal for ex-situ, in situ, and in operando measurements, allowing detailed probing of Li-metal deposits such as bulk, dendrites, or metallic filaments. Surface chemistry, phase transitions and structural changes are monitored and investigated nondestructively by with EPR spectroscopy.

Polymer Membrane Material Characterization using TD-NMR

The separator in a lithium-ion battery (LIB) serves to electrically isolate the anode from the cathode, while permitting the migration of lithium ions between the electrodes. The design and quality of the separator significantly influence the battery’s safety, thermal stability, and overall performance.

For electric vehicle applications, polypropylene (PP) and polyethylene (PE) are the predominant materials utilized in separator fabrication, though alternative polymer formulations and ceramic additives are also under active development.

Time-Domain Nuclear Magnetic Resonance (TD-NMR) is a rapid, non-destructive analytical technique extensively employed for characterizing polyethylene (PE) and polypropylene (PP). By measuring molecular mobility, TD-NMR provides direct insights into physical properties such as crystallinity, density, and crosslink density. This method is routinely applied in both research and development, as well as quality control within the polymer industry.

Monitoring & Optimization of Cathode Active Material (CAM) Production

Cathode Active Material, CAM, is the key component of a battery’s cathode, with CAM quality strongly influencing the energy density, cycle life, and overall performance of batteries.

The production of high-performance CAM requires precise quality control throughout the process, from the monitoring of calcination during production and microstructural analysis of the finished product, to solvent recovery analysis.

Bruker offers a range of X-ray and magnetic resonance based solutions to fine-tune this stage of production for an efficient process and high-quality CAM.

Quality Control of pCAM: Lattice Parameters and Site Mixing

pCAM is the intermediate material produced before the final CAM. It is typically derived from NCM sulfate solutions and undergoes further processing to achieve the desired structure and composition. Because pCAM directly influences the properties of NCM-based cathodes, rigorous quality control is critical at this stage to ensure consistent electrochemical performance and long-term stability.

X-Ray Diffraction (XRD) is an established method used to assess the crystallographic quality of pCAM. The anisotropic width and shape of the diffraction peak can be modeled in terms of probability of stacking faults in the precursor layered structure. Using Bruker's advanced XRD solutions manufacturers can verify structural integrity and optimize pCAM for high-performance NCM cathodes.

Monitoring Calcination during CAM Production

During CAM synthesis, hydroxide precursors undergo calcination to form the desired crystalline structure. Control of this thermal process is critical for the production of CAM with the correct phase composition and lattice integrity.

XRD provides real-time or post-process verification of phase transitions, ensuring complete conversion and detecting residual hydroxide phases. The monitoring of crystallite growth and microstrain development during calcination is also possible, helping optimize temperature profiles and dwell times.

With the D8 ADVANCE X-ray diffractometer manufacturers can ensure structural consistency and prevent defects that would otherwise compromise battery quality.

Compositional Analysis of Recovered Solvents

Solvent recovery helps reduce waste and maintain process efficiency during CAM production. X-Ray Fluorescence (XRF) enables rapid compositional analysis of recovered solvents, allowing manufacturers to quickly and accurately verify solvent purity and detect residual metals or contaminants. This ensures consistent recycling quality and prevents impurities from re-entering the production stream.

Compared to many wet-chemical or ICP methods, XRF provides a faster turnaround with minimal sample preparation, making it ideal for routine process monitoring steps such as this. Bruker provides both lab-based XRF spectrometers as well as handheld XRF devices for flexible use.

Structural and Morphological Quality Control of CAM

The quality of CAM defines the performance and reliability of batteries, meaning its structural and morphological integrity is critical. Quality control at this stage ensures that CAM meets stringent specifications for crystal structure and particle geometry.

X-Ray Diffraction (XRD) has become the industry-standard technique for crystallographic analysis and can deliver routinely precise measurement of lattice parameters, crystallite size, and phase purity - key indicators of structural stability and lithium-ion mobility. Detailed parameters such as atomic site position and site occupancy can also be refined, - e.g. lithium and nickel occupying incorrect lattice positions reducing battery capacity and accelerate degradation. Bruker’s XRD systems deliver high-resolution crystallographic analysis with advanced refinement tools, enabling manufacturers to confirm structural integrity and optimize CAM for consistent, high-performance batteries.

3D X-ray Microscopy (XRM/Micro-CT) complements structural analysis by offering non-destructive 3D imaging of particle size distribution, shape, and surface features. These factors affect electrode packing density, coating uniformity, and mechanical integrity. Detecting irregularities or foreign particles early helps prevent defects and improve reliability. Bruker’s 3D XRM solutions combine sub-micron resolution with automated particle segmentation, providing fast, accurate morphological analysis to ensure adherence to quality standards in CAM production.

Pre-Screening of NCM Particles

NCM (nickel-cobalt-manganese) particles are the primary active material in many lithium-ion battery cathodes, directly influencing energy density, cycle life, and safety.

The composition and microstructure determine how efficiently the battery stores and releases energy. Pre-screening NCM particles is essential to ensure uniformity and the absence of contaminants, helping prevent defects and performance losses in the final battery cells.

Our SEM-based solutions can be used for contaminant localization, particle analysis and in-depth microstructural evaluation.

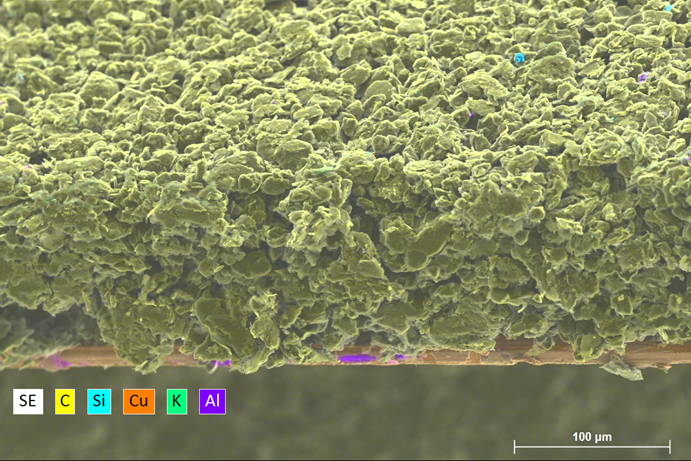

Contamination Screening and Mapping of NCM Particles at Bulk and Nanoscale

Screening NCM particles for contamination is critical because even trace impurities can degrade electrochemical performance. In addition, determining the location of contaminants helps to trace and eliminate their source. Energy Dispersive X-ray Spectroscopy (EDS) on a Scanning Electron Microscope is a powerful tool for spatial element analysis at the micro- to nanoscale.

The industry-leading XFlash® FlatQUAD EDS detector empowers users to quickly screen spherical particles both on the bulk and individual level, without the need for low-vacuum conditions or sample coating. The unique, annular design of this EDS detector facilitates ultra-fast, shadow-free mapping, enabling the accurate screening of hundreds of particles across millimeter-scale regions.

In addition to bulk analysis, the high-resolution data collected by XFlash® FlatQUAD facilitates the in-depth, spatial elemental analysis of individual particles with the identification and localization of contaminants as small as a few hundred nanometers.

Evaluating the Phase Purity and Microstructure of NCM Particles

The quantitative characterization of NCM particle microstructure is vital for ensuring consistent quality in battery production. High-resolution Electron Backscatter Diffraction (EBSD) mapping strengthens quality control processes, helping to ensure that NCM particles are of optimum microstructure.

Using the revolutionary eWARP, the fastest and most-sensitive EBSD detector ever, manufacturers can measure grain orientation and size distribution at the nanoscale in record time. Over 1,000 crystallites within a single NCM particle can be visualized, allowing users to verify microstructural uniformity and identify defects that could impact performance.

Top - High-resolution EBSD map of a NCM (nickel-cobalt-manganese) particles measured at 10 kV and 12 nA in less than 20 minutes.

Bottom - Grain size distribution histogram corresponding to a single particle of cathode material (insert). The particle contains more than 1,000 grains with an average diameter size of 428 nm.

Quality Control of Battery Cell Components

Prior to the manufacturing of battery cells, each component - such as the cathode, anode, electrolyte and polymer membranes - must be inspected for defects and contaminants. Failure to do this can result in malfunctioning or suboptimal batteries.

Bruker's solutions for cell component quality control include:

- X-Ray Diffractometers (XRD) to verify crystal structure and texture

- 3D X-Ray Microscopes (XRM) to non-destructively inspect internal components in three dimensions

- Micro-XRF to quickly detect and localize trace contaminants

- Nuclear Magnetic Resonance (NMR) to probe local structure, ion mobility, and electrolyte quality

- Time- Domain NMR (TD‑NMR) to check polymer membrane integrity, slurry homogeneity and the solid fraction

Electron Paramagnetic Resonance (EPR) to reveal paramagnetic defects, electronic structure, charge storage, and degradation mechanisms of battery raw materials

In combination, these tools help manufacturers ensure cell components are of high quality and consistency before being assembled into cells.

Cathodes: Particle Analysis and Defect Identification

The internal structure of cathodes can be inspected for uniformity and structural integrity using 3D XRM/micro-CT. Equipped with an X-ray microscope, manufacturers can image cathode particles in three dimensions to determine particle size and distribution, and to identify voids or microcracks. This non-destructive analysis helps identify any defective cathodes and avoid their integration into battery cells.

Bruker’s X4 POSEIDON X-ray microscope provides high-resolution 3D imaging with automated measurements, making it easier for manufacturers to integrate strict quality control into the manufacturing processes.

Cathodes: Identifying Structural Changes from Charging and Discharging

The local structure and ion dynamics within cathode materials play a decisive role in performance, degradation mechanisms and cycle life. Techniques capable of probing short‑range order, disorder and ion mobility are therefore essential to understand these processes.

Solid-state Nuclear Magnetic Resonance spectroscopy (ssNMR) is used to analyze the local structure of cathode materials to identify phase changes and structural distortions that occur during charging and discharging.

This includes detecting lithium/sodium ion environments in disordered systems. ssNMR directly probes ion mobility (e.g., 7Li, 6Li) at various timescales, allowing for the study of lithium-ion diffusion within the cathode and is crucial for analyzing the Cathode Electrolyte Interphase (CEI), which governs battery longevity and efficiency. Bruker’s ssNMR solutions provides molecular and atomic-level insights into cathode active materials, enabling optimization of battery performance and manufacturing quality control.

Anodes: Structural Analysis and Orientation Index Determination

The 3D inspection of anode materials is also possible via XRM with the X4 POSEIDON, where it facilitates the quantitative analysis of particle shape, alignment and internal structure.

The additional use of XRD provides an extra layer of vital information, allowing manufacturers to verify crystal structure and texture in the graphite anode, which are both important factors for efficient ion transport. Bruker’s D8 ADVANCE X-ray diffractometer delivers fast, accurate crystallographic analysis, enabling manufacturers to precisely monitor anode quality. Its advanced detector technology and flexible configuration support use at a range of scales.

In combination, XRD and 3D XRM help manufacturers ensure that anodes are well-formed and free from structural issues.

Slurry: Homogeneity Analysis with TD-NMR

The physical and chemical properties of the slurry, along with its uniform deposition on the electrode, are critical quality control parameters. These characteristics are strongly influenced by mixing conditions such as screw speed, mixing time, and accurate ingredient dosing. Maintaining slurry homogeneity is crucial for material stability, which improves both the safety and lifespan of battery cells, ultimately leading to cost savings.

The Bruker minispec provides time domain NMR (TD-NMR) technology in a compact benchtop format, delivering important information on molecular structure, dynamics, and interactions. Designed for ease of use, it allows non-experts to obtain quick and reliable results with minimal sample preparation. This technique is especially effective for early detection of sedimentation in slurry samples, quantifying solid content, monitoring formulation ratios (active material, conductive additives, and binder), assessing homogeneity, and identifying de-mixing phenomena.

Polymer Membranes: Contamination Detection and Pore-Size Analysis

Polymer membranes and separators must be free from contaminants, which would otherwise interfere in electrochemical processes, and have the correct pore size and structure to facilitate ion transport.

Trace metals or other unwanted particles within membranes can be quickly detected and localized using micro-XRF spectroscopy. The M4 TORNADO is a desktop spectrometer that fits easily on the benchtop of a QC lab for the rapid detection of contaminants at trace levels.

3D XRM provides detailed imaging of pore size and distribution, ensuring membranes meet design specifications. By combining these tools, manufacturers can maintain high cleanliness standards and optimize membrane performance.

Polymer Binder: PVDF characterization

Polyvinylidene fluoride (PVDF) is a critical component inlithium-ion batteries (LIBs), acting primarily as the binder in cathodes to hold active materials together and adhere them to the metal current collector.

High-resolution multinuclear NMR (19F, 1H, 13C) characterizes PVDF chain microstructure, including head-to-tail regiodefects, branching, and chain-end structures. Solid-state NMR, particularly 19F MAS, distinguishes crystalline phases (α, β, γ) and amorphous domains, while PFG-NMR measures ionic mobility in PVDF-based electrolytes.

Quality Control of Manufactured Battery Cells

Following the assembly of the components into a battery cell rigorous testing is required to ensure performance, safety, and quality standards are adhered to. Quality control is critical for the identification of hidden defects, verification of internal structure, and to confirm that each battery cell will operate reliably in real-world conditions.

Bruker’s 3D X-Ray Microscopy (XRM) solutions enable the non-destructive, high-resolution 3D imaging of the battery cells internal structure.

Complementing this, Bruker’s X-Ray Diffraction (XRD) and solid-state Nuclear Magnetic Resonance (ssNMR) systems provide precise information on the material's structure. Together these techniques deliver comprehensive insights into the quality, stability and expected performance of a battery cell throughout its lifecycle.

Monitoring Cell Changes During Cycling with Operando Measurements

Operando measurements are the analysis of battery cells in real time whilst actively cycling through charge and discharge under realistic operating conditions.

This in-situ approach allows manufacturers and researchers to observe any changes in a battery cell's internal structure, such as phase transformations, gas formation or degradation, during use. Operando analysis helps manufacturers avoid issues such as unexpected capacity loss, safety risks, or premature failure that may not be detected using traditional inspection methods.

Operando measurements can be performed using XRD, 3D XRM ssNMR or micro-XRF.

Operando Measurements using X-Ray Diffraction

Operando XRD measurements allow users to monitor changes in the crystal structure of battery electrodes during cell cycles. XRD allows users to observe phase changes in cathode and anode materials and quantify lattice parameters during charging and discharging.

The rapid data acquisition and high sensitivity of Bruker's D8 ADVANCE allow manufacturers to record detailed structural information in real time.

Operando Measurements using X-Ray Microscopy

Operando XRM delivers high-resolution, three-dimensional imaging of the battery’s internal architecture while the cell is operating. This approach is used to visualize dynamic changes during cycling such as gas formation and electrode expansion.

The benchtop X4 POSEIDON excels in delivering fast, non-destructive imaging and time-lapse sequences, enabling users to pinpoint potential points of failure.

Operando Measurements using solid state NMR

To meet market needs, manufacturers need to optimize their production processes, improving throughput, speed, efficiency and resource utilization. In-depth investigations are fundamental to addressing these challenges and techniques such as solid-state in-situ NMR spectroscopy offer a reliable, comprehensive analytical tool.

Bruker offers customizable solutions, such as the combined Bruker and ePROBE offering, an operando probe equipped with current collector ports to enable charging and discharging of electrochemical cells while being inside the NMR magnet. In addition, the probes are equipped with integrated flow channels for gas or liquid to enable experiments on redox-flow, metal-air batteries, and similar systems. Bruker’s complete, high-quality solutions, have been specifically developed to meet the needs of battery research within academia and industry.

Operando Measurements using micro-XRF

Operando micro-XRF is an emerging technique to monitor the spatial distribution of key elements within electrodes and across interfaces during cell cycling.

Recent advances, including confocal micro-XRF with the M4 TORNADO, allow for depth profiling and even 3D imaging of elemental changes, making it possible to monitor processes such as metal deposition and ion migration in situ.

Operando micro-XRF is a developing field, with recent publications demonstrating its application to real battery cells using X-ray transparent windows.

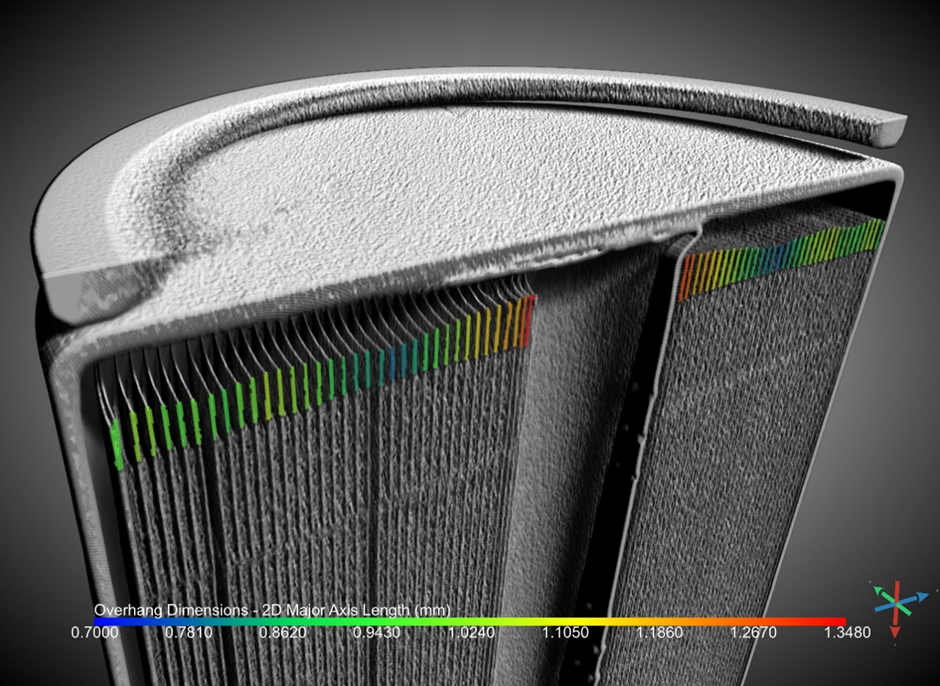

Internal Inspection and Safety Testing of Battery Cells

The internal design and construction of battery cells can also be achieved via 3D XRM/micro-CT with the X4 POSEIDON. This benchtop X-ray microscope gives manufacturers the ability to visualize the internal structure of fully assembled cells in three dimensions, without the need to open or destroy the sample. With XRM, users can precisely measure critical design features such as anode overhang, helping ensure proper alignment and safety margins within the cell.

In addition to overhang analysis, XRM gives manufacturers the ability to detect delamination between layers and identify layer cracks that can develop during manufacturing or handling. By providing clear, high-resolution images of the internal architecture, XRM enables quality control teams to identify these issues early and make informed decisions about process improvements or product acceptance.

Safety testing of battery cells, such as evaluating the impact of a nail puncture, can also be performed via XRM. Using the X4 POSEIDON manufacturers can non-destructively visualize the impact of mechanical intrusion on internal layers, identifying crack propagation, layer separation, or gas formation. Detailed 3D imaging helps manufacturers assess the effectiveness of safety mechanisms and improve cell designs.

Failure Analysis during Battery Manufacturing

In battery cell manufacturing, failure analysis is essential for identifying and addressing potential issues that may lead to premature battery failure or safety concerns. By pinpointing the root causes of failures, manufacturers can implement corrective measures during the manufacturing process, effectively preventing similar issues from recurring.

This proactive approach not only enhances productivity and efficiency but also results in significant cost savings. Understanding the causes of battery cell failures allows for continuous process improvements, ensuring that manufacturing operations are both streamlined and economically viable.

In-situ Nuclear Magnetic Resonance (NMR) spectroscopy provides atomic-level insights into battery materials, enabling manufacturers to optimize electrode compositions, electrolytes, and separators.

Bruker’s Avance NMR solutions provides automated workflow to enhance user efficiency, requiring little to no time for instrument setup, calibration, and validation. The user-friendly interface ensures smooth operation with minimal NMR expertise needed. The solution includes a pre-built and validated method for measuring ionic conductivity, identifying and quantifying product degradation and establishing breakdown pathways throughout the cell lifecycle.

Battery Recycling & Black Mass Analysis

Battery recycling is essential for sustainable battery production, offering significant economic and environmental benefits. By recovering valuable metals from spent batteries through black mass analysis, manufacturers can reduce dependence on volatile supply chains and lower production costs.

Efficient metal recovery ensures that critical elements like lithium, nickel, cobalt, and rare earth elements (REEs) are returned to the supply chain, supporting a circular economy and helping companies meet regulatory and sustainability goals.

Bruker’s advanced solutions enable precise elemental and compositional analysis of black mass, providing the data needed to optimize recycling processes and maximize the recovery of valuable metals.

Compositional Analysis of Battery Black Mass

The fast and precise compositional analysis of black mass is made possible using Bruker's X-Ray Fluorescence (XRF) solutions. These advanced instruments deliver rapid, non-destructive elemental analysis, allowing researchers and recycling operators to accurately determine the concentration of valuable metals and monitor impurity levels in battery recycling streams.

Bruker’s XRF solutions are designed with speed, sensitivity, and reliability in mind, making them an excellent choice for optimizing metal recovery and ensuring a high quality of recycled battery materials. For compositional analysis in the lab desktop and floor-standing XRF spectrometers are available or, for flexible but accurate analysis on the production floor we recommend a handheld XRF device.

Lithium Recovery Monitoring in Battery Recycling

Nuclear Magnetic Resonance (NMR) spectroscopy can be used to monitor the efficiency of lithium extraction from shredded battery waste or leaching liquors (e.g., from cathode materials like NMC) in real-time. This helps optimize the chemical processes, such as identifying the optimal conditions for lithium recovery.

NMR also supports battery recycling by enabling precise, real-time, and quantitative analysis of N-Methyl-2-pyrrolidone (NMP) recovery processes, ensuring the solvent is pure enough for reuse in cathode slurry production. As a critical solvent used to dissolve polymer binders in cathode manufacturing, NMP recovery is essential for cost-effective, sustainable direct recycling of production scrap.

From Start to Finish: Improve Quality Throughout the Battery Manufacturing Process

Bruker's wide range of analytical solutions deliver value throughout the battery production and recycling, with each finding application and helping to improve quality at multiple process stages.

Find out more about each technology and their application in the battery industry below.