Quantification of Steels and Alloys using a dual source multidetector system. Part II: SEM-WDS adding to XRF-EDS and SEM-EDS analysis

EDS and WDS Element Analysis of Steels & Alloys

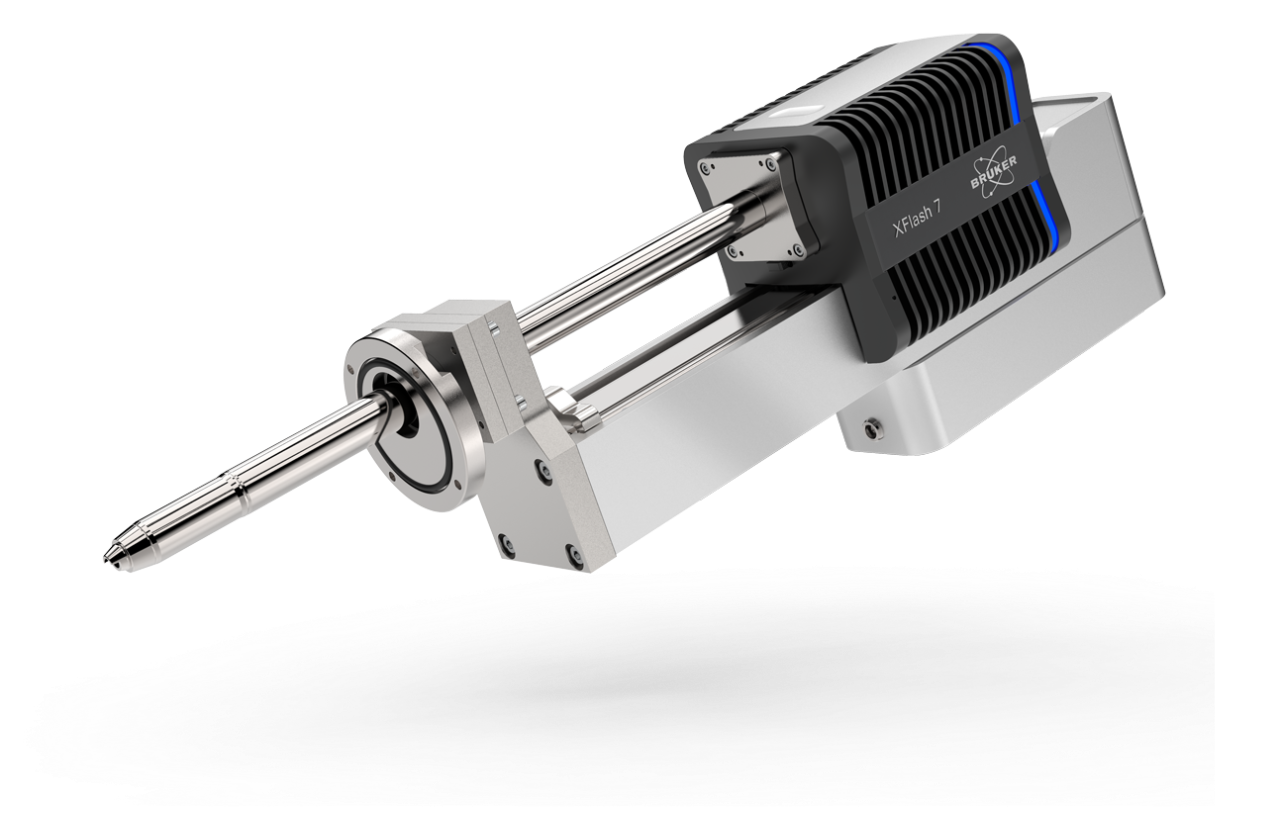

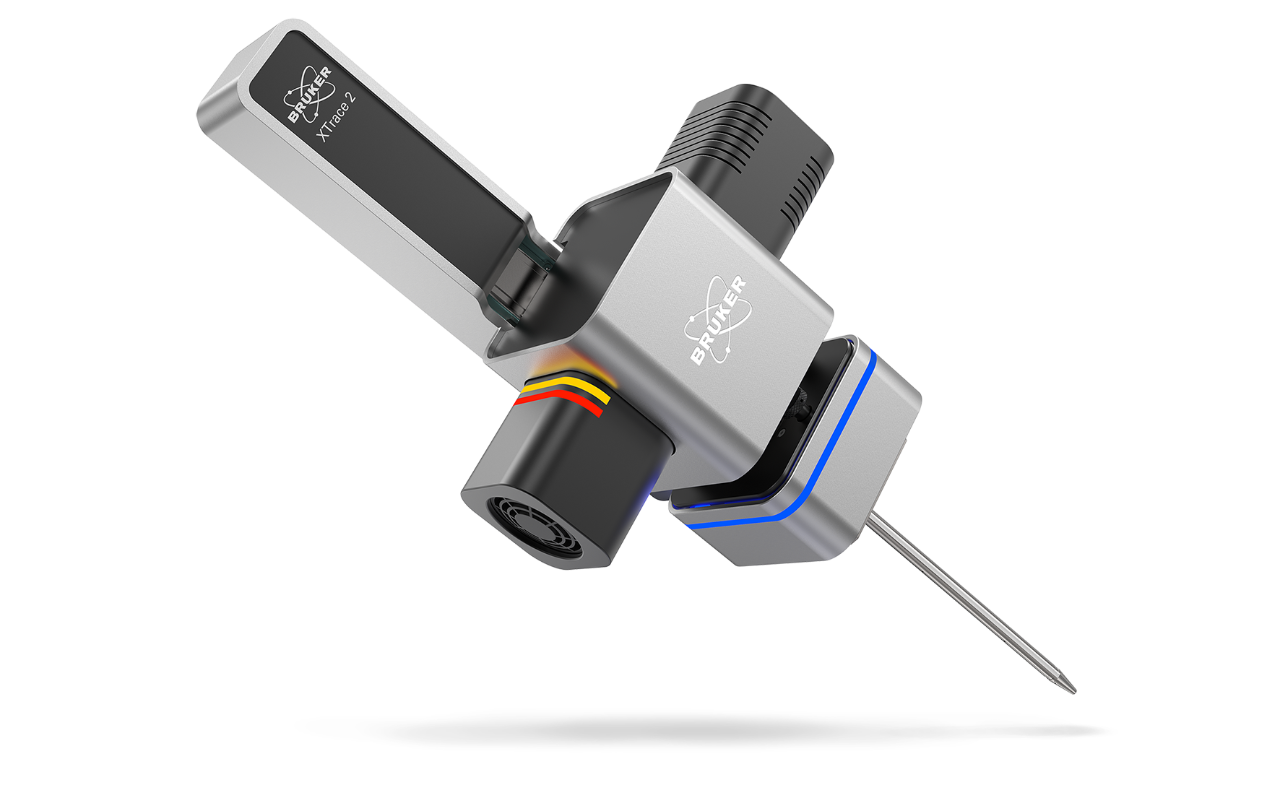

Quantification of steels and alloys can be problematic due to the various elements of interest and the range of concentrations present from majors through to traces. This two-part webinar will show the benefits of using a dual-beam system, that is, a system that has both an electron and micro-XRF source. In addition, this system is equipped with an energy dispersive spectrometer (EDS) and a wavelength dispersive spectrometer (WDS). Preceding Part I of this webinar series focused on the dual-beam sources, and the respective advantages of electron and photon excitation for X-ray analysis. Part II will now compare these results with the measurements using the WDS collected on the same system. We will show that WDS adds value to the combined analysis when certain trace elements or light elements are of interest, when peak overlaps are present or when high spatial resolution is required. The samples used for this webinar are a range of certified steels with variable concentrations of Cr and Ni, expected for those used in industry, as well as quantifying minor and trace elements, like Cu, Mo, S, Si, Al, P, N and C. The results demonstrate the capabilities and benefits of using a dual source multi detector system. The webinar will be rounded off by a 15-minute Q&A session where our experts will answer your questions.

Who should attend?

- Everyone dealing with an application where quantification is required

- Researchers from industry and academia who investigate steels or alloys

Speakers

Stephan Boehm

Product Manager - micro-XRF on SEM and WDS, Bruker Electron Microscope Analyzers

Dr. Michael Abratis

Sr. Application Scientist, Bruker Electron Microscope Analyzers

Watch this Webinar On-Demand

Please enter your details below to gain on-demand access to this webinar.